2007 Honda Odyssey Air Conditioner Recharge

The 2007 Honda Odyssey, a mainstay in the minivan segment, features a robust air conditioning system critical for passenger comfort. While seemingly straightforward, understanding its intricacies allows automotive professionals to perform efficient and reliable recharges. This article delves into the specifics of the 2007 Odyssey's AC system, comparing it with alternatives, highlighting reliability concerns, and offering maintenance advice.

Technical Specifications & Engineering Choices

The 2007 Odyssey's AC system utilizes R-134a refrigerant, a standard for vehicles of that era. The system consists of the following key components:

- Compressor: A variable displacement compressor, typically a Sanden model, driven by the engine via a belt. Its variable displacement capability adjusts cooling output based on demand, improving fuel efficiency.

- Condenser: Located in front of the radiator, the condenser dissipates heat from the high-pressure refrigerant gas, turning it into a high-pressure liquid.

- Receiver-Drier: This component filters contaminants and removes moisture from the refrigerant. It also contains a desiccant which needs periodic replacement.

- Expansion Valve: A thermal expansion valve (TXV) regulates the flow of refrigerant into the evaporator core, controlling the degree of cooling. The TXV in this system is particularly susceptible to clogging if the system is contaminated.

- Evaporator Core: Located within the dashboard, the evaporator core absorbs heat from the cabin air, cooling it before being circulated.

- Refrigerant Lines: Aluminum and rubber lines transport the refrigerant throughout the system. These lines are prone to leaks over time, especially at connection points.

Honda's choice of a variable displacement compressor, instead of a simpler on/off clutch-type compressor, reflects a focus on fuel efficiency and smoother cooling. The system also incorporates pressure switches to protect the compressor from damage due to low or high refrigerant pressure.

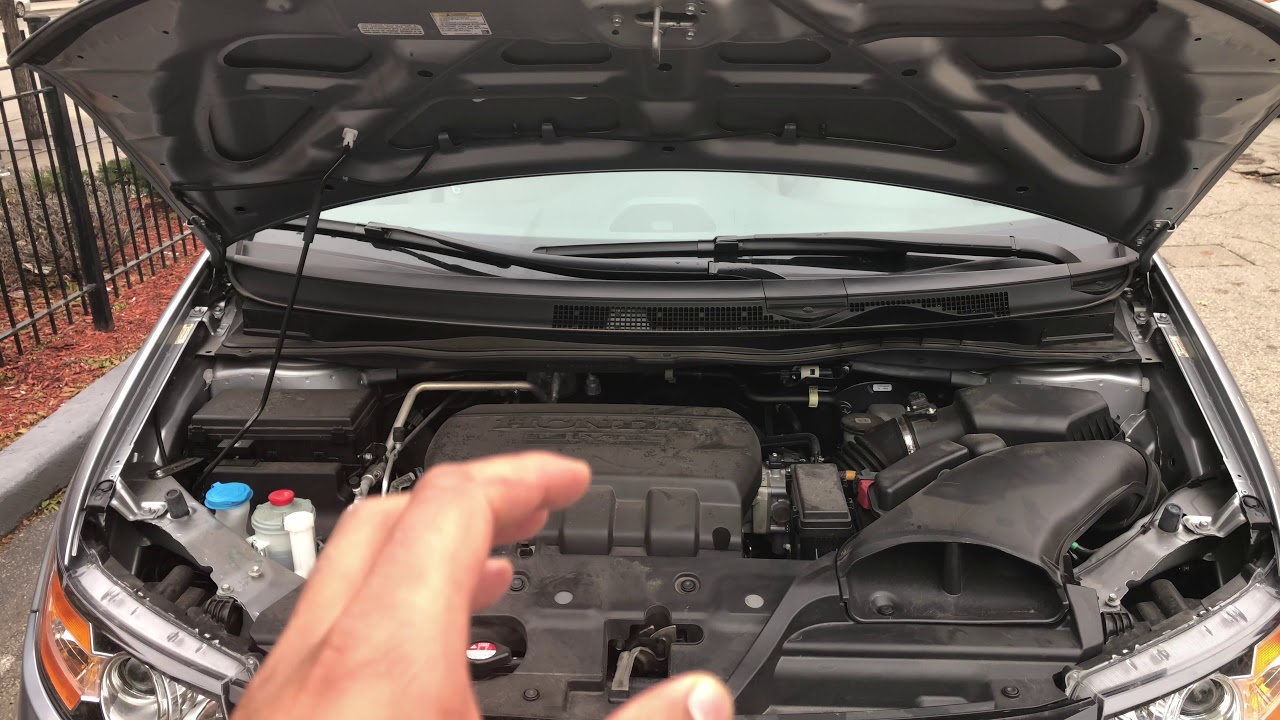

Recharge Procedure & Considerations

Recharging the 2007 Odyssey's AC system requires careful attention to detail. Before initiating a recharge, it's crucial to identify the cause of the refrigerant loss. Common causes include leaks in the refrigerant lines, condenser, or compressor shaft seal. A leak test using UV dye and a black light is recommended to pinpoint the leak source before adding refrigerant. Simply adding refrigerant without addressing the leak is a temporary fix and environmentally irresponsible.

Proper charging procedure:

- Evacuate the system using a vacuum pump to remove air and moisture. A deep vacuum (typically around 29 inches of mercury) should be held for at least 30-45 minutes to ensure complete dehydration.

- Verify the system holds vacuum. If vacuum drops, there's a leak that needs addressing.

- Add the correct amount of R-134a refrigerant. The 2007 Odyssey typically requires around 24-26 ounces of refrigerant. Consult the vehicle's service manual or the sticker under the hood for the precise amount. Overcharging or undercharging can negatively impact performance and potentially damage the compressor.

- Monitor the high and low side pressures after charging. Use a manifold gauge set to ensure the pressures are within the specified range for the ambient temperature.

Alternatives & Comparisons

While R-134a was the standard at the time, newer vehicles are transitioning to R-1234yf, a refrigerant with a lower global warming potential. Retrofitting an older system to use R-1234yf is generally not recommended due to compatibility issues and potential damage to the AC components. The cost of conversion outweighs the benefits for most owners of older vehicles.

Comparing the 2007 Odyssey's AC system with other minivans of that era, such as the Toyota Sienna or Dodge Caravan, reveals similar approaches to refrigerant choice and component design. However, some vehicles might employ different compressor technologies or condenser designs, affecting overall cooling efficiency and reliability.

Reliability, Maintenance & Troubleshooting

The 2007 Odyssey's AC system is generally reliable, but several factors can affect its performance and longevity.

- Refrigerant Leaks: As mentioned earlier, leaks are a common issue. Regular inspections of refrigerant lines and components are crucial.

- Compressor Failure: Compressor failure can occur due to age, lack of lubrication, or contamination. Signs of compressor failure include unusual noises, weak cooling, and a seized compressor.

- Condenser Corrosion: The condenser is exposed to road debris and corrosive elements, leading to corrosion and leaks.

- Expansion Valve Clogging: Debris and contaminants can clog the expansion valve, restricting refrigerant flow and reducing cooling performance.

- Electrical Issues: Problems with the AC clutch relay, pressure switches, or blower motor can also disrupt the system's operation.

Maintenance Tips:

- Run the AC system regularly, even during colder months, to circulate refrigerant and lubricant.

- Replace the cabin air filter regularly to maintain good airflow through the evaporator core.

- Consider having the AC system professionally serviced every few years to check for leaks, refrigerant levels, and component condition.

Future Trends

The automotive industry is moving towards more environmentally friendly refrigerants and advanced AC system technologies. R-1234yf is becoming the new standard, and electric vehicles are employing heat pumps for both heating and cooling. These systems offer improved efficiency and reduced emissions.

Forward-Looking Note

As technology evolves, automotive professionals must stay updated on the latest AC system designs, refrigerants, and diagnostic techniques. Embracing new technologies and prioritizing environmentally responsible practices will be crucial for the future of the automotive service industry. Continuous training and investment in advanced diagnostic equipment are essential for success. The increasing complexity of automotive systems demands a highly skilled and knowledgeable workforce.