2008 Ford F350 6.4 High Pressure Fuel Pump

The 2008 Ford F350, particularly those equipped with the 6.4L Power Stroke diesel engine, is a workhorse admired for its towing capacity and overall durability. However, a known Achilles' heel of this engine is the High-Pressure Fuel Pump (HPFP), also known as the CP4 pump. Understanding the intricacies of this component is crucial for owners, mechanics, and anyone considering purchasing or working on these trucks.

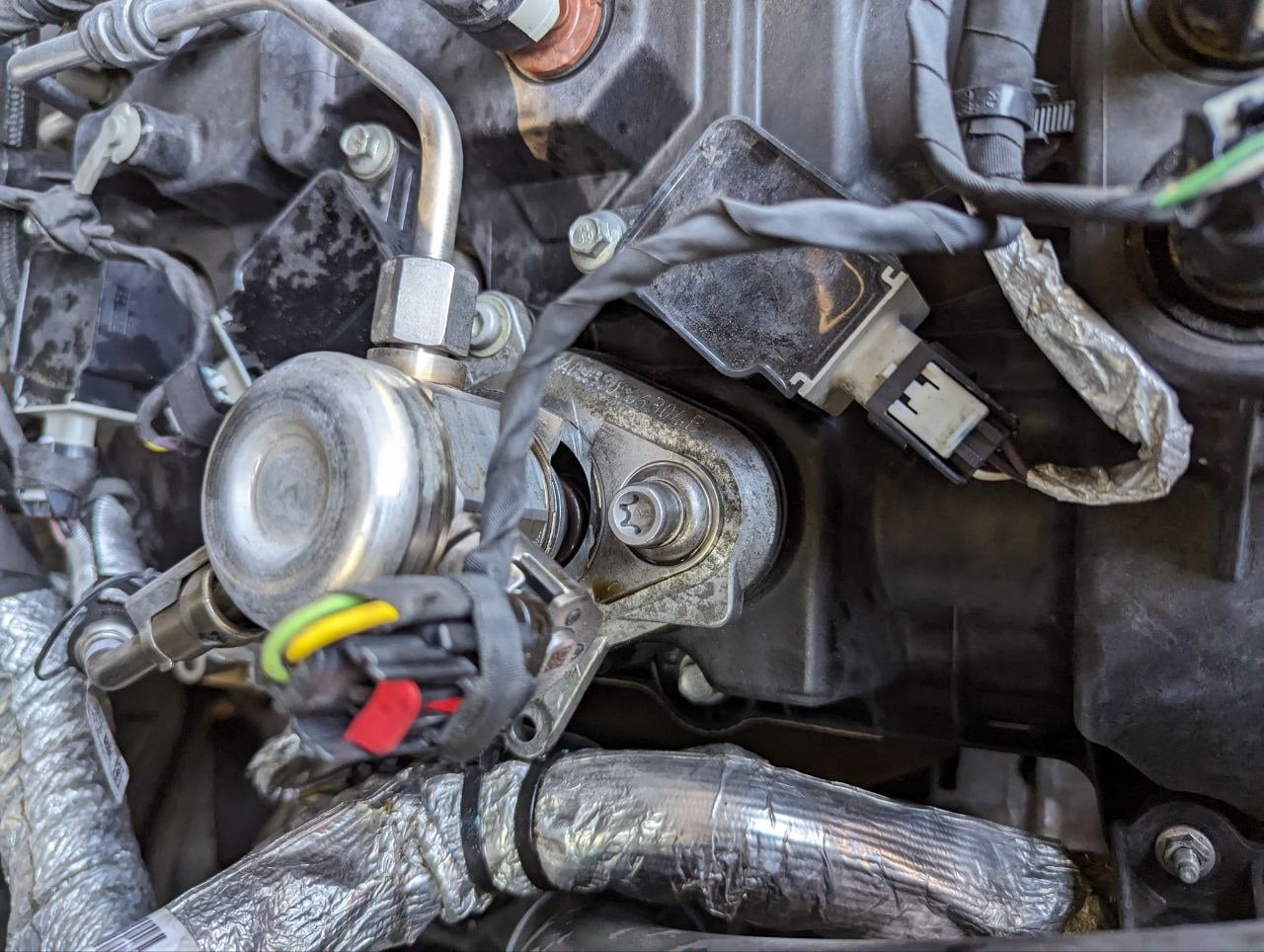

The CP4 HPFP: Design and Function

The 6.4L Power Stroke utilizes a CP4 injection pump, a design adopted by many diesel manufacturers to meet stringent emissions standards. Its primary function is to pressurize fuel from the low-pressure fuel system (typically around 5-10 PSI) to extremely high pressures (over 26,000 PSI) required by the common rail fuel injection system. This high-pressure fuel is then delivered to the injectors, which precisely meter and spray fuel into the cylinders for combustion.

Unlike its predecessor, the CP3 pump found in earlier Power Stroke engines, the CP4 is a single-piston pump. While smaller and potentially more efficient, this design introduced a significant vulnerability. The CP4 relies heavily on fuel lubricity. If the fuel isn't sufficiently lubricious, or if contamination enters the system, the rollers and camshaft within the pump can experience excessive wear. This wear generates metal debris, which then contaminates the entire fuel system – injectors, fuel rails, and even the fuel tank.

Failure Symptoms of the 6.4L Power Stroke HPFP

Recognizing the symptoms of a failing HPFP is critical for preventing catastrophic engine damage. Common warning signs include:

- Hard Starting or No Start: Difficulty starting, especially when the engine is cold, or a complete inability to start.

- Reduced Power and Performance: Noticeable decrease in engine power, acceleration, and overall performance.

- Rough Idling: Unstable or erratic engine idling.

- Fuel Knocking: An unusual knocking or pinging sound originating from the engine, potentially indicating issues with fuel delivery or combustion.

- Check Engine Light (CEL): Illumination of the check engine light with diagnostic trouble codes (DTCs) related to fuel pressure or injection system malfunctions. Codes like P0087 (Fuel Rail/System Pressure - Too Low) are often indicative.

- Metal Flakes in Fuel Filter: This is the most definitive symptom. Regularly inspecting the fuel filter for metallic particles is crucial for early detection.

Causes of HPFP Failure

Several factors contribute to the premature failure of the 6.4L Power Stroke's CP4 pump:

- Poor Fuel Lubricity: Ultra-Low Sulfur Diesel (ULSD) fuel inherently has lower lubricity than previous diesel formulations. Without adequate additives or supplements, the CP4 pump experiences increased wear.

- Fuel Contamination: Water, dirt, or other contaminants in the fuel can quickly damage the pump's internal components.

- Air in Fuel System: Air pockets in the fuel lines can cause cavitation and damage to the pump.

- Fuel Additives (Potential Issues): While some additives can improve lubricity, others can be detrimental. Ensure any fuel additive used is specifically formulated for common rail diesel systems and follow the manufacturer's instructions carefully.

Repair and Prevention Strategies

Unfortunately, a failed CP4 HPFP often necessitates a complete fuel system replacement, including the pump, injectors, fuel rails, and fuel tank, to eliminate any residual metal debris. This is a costly repair, typically ranging from $6,000 to $10,000 or more.

Preventative measures are crucial for extending the life of the HPFP:

- Use Fuel Additives: Regularly use a high-quality fuel additive specifically designed to increase lubricity in ULSD fuel.

- Maintain Fuel Filter: Replace the fuel filter at the recommended intervals (or even more frequently) to ensure clean fuel is reaching the pump.

- Check for Fuel Leaks: Promptly address any fuel leaks in the system to prevent air from entering.

- Consider a CP3 Conversion: For those seeking a more robust and reliable solution, consider a CP3 pump conversion. This involves replacing the CP4 pump with the older, more durable CP3 pump. While more expensive upfront, it can provide long-term peace of mind.

In conclusion, the 2008 Ford F350 6.4L Power Stroke's HPFP is a known weak point. By understanding the pump's design, recognizing failure symptoms, and implementing preventative maintenance strategies, owners and mechanics can significantly mitigate the risk of costly repairs and keep these powerful trucks on the road.