How Many Quarts In A Turbo 400 Transmission

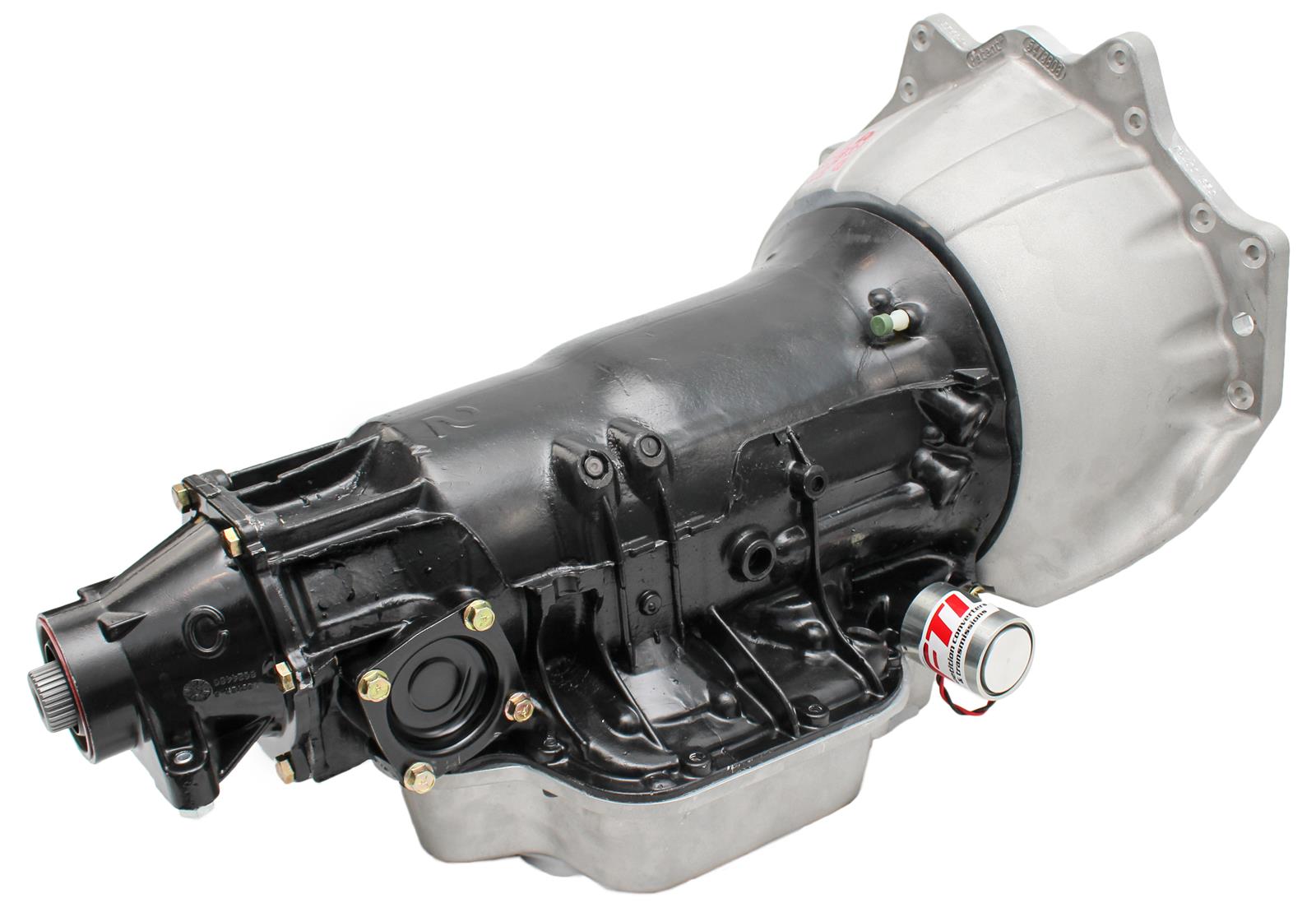

The Turbo 400, also known as the TH400 or 3L80, remains a stalwart in the world of automatic transmissions. Finding precise information regarding its fluid capacity can sometimes be confusing, especially when accounting for various aftermarket modifications and applications. This article aims to provide a comprehensive overview of the TH400's fluid capacity, delve into the technical aspects that influence it, compare it to alternative transmissions, and offer insights into its reliability, maintenance, and future relevance.

Understanding TH400 Fluid Capacity

The stock Turbo 400 transmission typically holds around 9-11 quarts of automatic transmission fluid (ATF) when completely dry, such as after a rebuild. However, this figure is somewhat misleading. In a typical fluid and filter change scenario, you'll likely only drain about 5-6 quarts. This is because a significant amount of fluid remains trapped in the torque converter, valve body, and cooler lines.

Several factors influence the actual fluid capacity. These include:

- Torque Converter Size: Larger torque converters naturally hold more fluid. Aftermarket, high-stall converters, for instance, can increase the overall system capacity significantly.

- Cooling System: An external transmission cooler, whether factory-installed or aftermarket, adds to the total fluid volume. The size and length of the cooler lines also play a role.

- Pan Depth: Deep transmission pans, popular for increased fluid capacity and cooling, directly affect the amount of fluid required.

- Transmission Year and Specific Variant: While the core design remained relatively consistent, minor variations existed across different model years and applications. These variations can sometimes influence the internal fluid pathways and thus, the total capacity.

Technical Specifications and Engineering Choices

The TH400's robust three-speed design was engineered for high-torque applications. Its cast-iron case and heavy-duty internal components contribute to its legendary durability. However, these features also make it heavier and less fuel-efficient compared to more modern transmissions. The TH400 utilizes a planetary gearset for speed changes, a design known for its strength and reliability.

The valve body is a critical component, controlling fluid flow to engage different gears. Modifications to the valve body are common, ranging from shift kits for firmer shifts to full manual valve bodies for racing applications. These modifications can subtly alter the overall fluid requirements.

Comparison with Alternatives

Alternatives to the TH400 include the Turbo 350 (TH350), 4L60E, and more modern transmissions like the 6L80E and 8L90E. Here's a brief comparison:

- TH350: Lighter and more compact than the TH400, but not as strong. Good for moderate horsepower applications where weight savings are important.

- 4L60E: A four-speed electronically controlled transmission. Offers better fuel economy and an overdrive gear compared to the TH400, but generally not as durable in high-horsepower applications without significant upgrades.

- 6L80E/8L90E: Modern six- and eight-speed transmissions offering superior fuel economy and performance. Require electronic control and are more complex to install in older vehicles.

Pros of TH400: Extremely durable, simple to rebuild, readily available parts, relatively inexpensive. Cons of TH400: Heavy, only three speeds, poor fuel economy, significant parasitic power loss.

Reliability and Maintenance

The TH400's reliability is legendary, but proper maintenance is still crucial. Regular fluid and filter changes are essential for longevity. Using the correct type of ATF is also vital. While Dexron III was originally specified, many modern synthetic ATFs that are compatible with Dexron III are available and often offer improved performance and protection.

Signs of a failing TH400 include slipping gears, harsh or delayed shifts, unusual noises, and fluid leaks. Addressing these issues promptly can prevent more serious damage. Overheating is a major killer of automatic transmissions, so ensuring adequate cooling is paramount, especially in high-performance applications.

Future Trends

While the TH400 is an older design, it remains popular in drag racing and other motorsports due to its strength and simplicity. However, the trend in the automotive industry is towards more efficient and sophisticated transmissions with more gears. Modern electronically controlled transmissions offer better fuel economy, smoother shifts, and more precise control.

Despite the shift towards newer technologies, the TH400 will likely remain a relevant option for specific applications where durability and simplicity are paramount. Aftermarket support will continue to be strong, ensuring its availability for years to come.

Forward-Looking Note

The automotive industry is undergoing a rapid transformation with the rise of electric vehicles and advanced driver-assistance systems (ADAS). While the future of traditional automatic transmissions may be uncertain, the core principles of power transmission and control will remain essential. Automotive professionals must adapt to these changes by embracing new technologies and developing expertise in areas such as electric drivetrain maintenance and software diagnostics. Even venerable designs like the TH400 serve as a reminder of the importance of robust engineering and reliable performance, qualities that will continue to be valued in the automotive world for the foreseeable future.