2 Wire Oil Pressure Switch Wiring Diagram

The 2-wire oil pressure switch is a critical component in your car's engine monitoring system. It provides a basic, yet essential, indication of oil pressure. Understanding how it works, how to maintain it, and how to troubleshoot common problems can save you from costly engine damage. This article focuses on the practical aspects of dealing with this often-overlooked sensor.

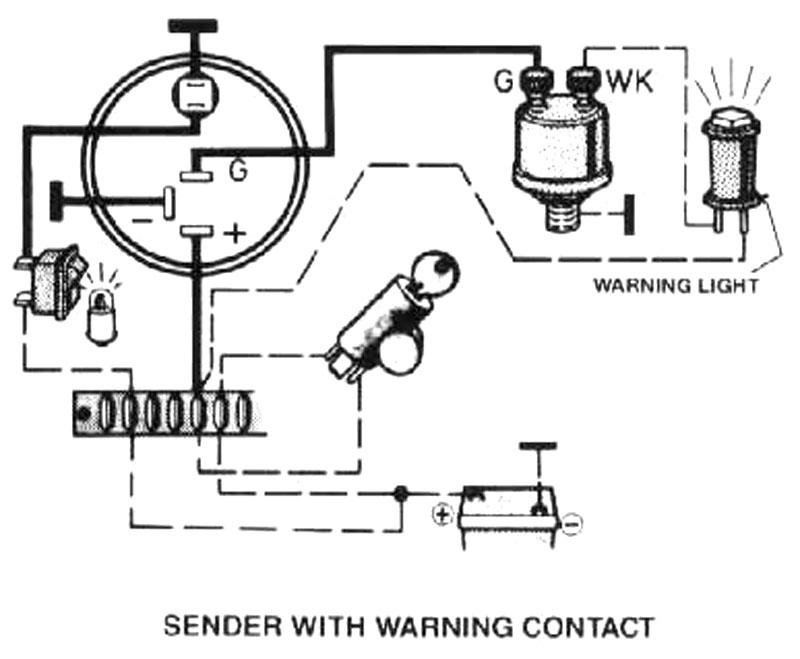

Understanding the 2-Wire Oil Pressure Switch

Unlike more sophisticated oil pressure sensors that provide a variable voltage signal to the engine control unit (ECU), the 2-wire oil pressure switch is a simple on/off device. It essentially acts as a pressure-activated switch. One wire typically provides a 12V power source, and the other wire connects to either the oil pressure warning light in the dashboard or, in some cases, to the ECU for a basic pressure check. When the oil pressure is above a certain threshold (typically around 5-7 PSI), the switch opens, disconnecting the circuit and turning off the warning light. When the pressure drops below the threshold, the switch closes, completing the circuit and illuminating the warning light.

Maintenance: Keeping it Clean and Connected

Preventative maintenance on a 2-wire oil pressure switch is relatively straightforward. The main concerns are corrosion and loose connections. Here's what you can do:

- Visual Inspection: Regularly inspect the switch and its wiring for signs of damage, corrosion, or oil leaks. Look for cracked insulation on the wires, rust on the terminals, and oil seepage around the switch body.

- Cleaning the Connections: If you find corrosion, disconnect the wiring harness from the switch. Clean the terminals with a wire brush or electrical contact cleaner. Apply a small amount of dielectric grease to the terminals before reconnecting to prevent future corrosion.

- Checking Wire Integrity: Gently tug on the wires near the connector to ensure they are securely attached. Loose wires can cause intermittent or complete loss of signal.

Troubleshooting: Problem-Solution Approach

Let's address some common problems you might encounter with a 2-wire oil pressure switch:

Problem 1: Oil Pressure Light Stays On

Symptom: The oil pressure warning light on your dashboard remains illuminated even after the engine has started and is running normally.

Possible Causes:

- Low Oil Pressure: This is the most serious cause! Immediately check your oil level and listen for unusual engine noises. If the oil level is normal and the engine sounds fine, proceed with the following steps.

- Faulty Oil Pressure Switch: The switch might be stuck in the closed position, even when oil pressure is adequate.

- Short to Ground in Wiring: The wire connecting the switch to the warning light could be shorted to ground, completing the circuit and turning on the light.

- Faulty Wiring: A break or corrosion in the wire can lead to incorrect signals.

Solutions:

- Verify Oil Level: Ensure the engine has sufficient oil.

- Test the Switch: Disconnect the wire from the switch. If the light goes off, the switch is likely faulty and needs replacement. You can also test the switch with a multimeter. With no oil pressure, the switch should show continuity (a closed circuit). With sufficient oil pressure, it should show no continuity (an open circuit).

- Inspect the Wiring: Carefully inspect the wiring harness for any signs of damage or chafing. Use a multimeter to check for a short to ground. With the wire disconnected from the switch, test for continuity between the wire and the vehicle's chassis (ground). There should be no continuity.

- Replace the Switch: If the switch is faulty, replace it with a new one of the correct specification for your vehicle.

Problem 2: Oil Pressure Light Doesn't Come On During Start-Up

Symptom: The oil pressure warning light does not illuminate when you turn the ignition key to the "on" position (before starting the engine). This is a crucial self-test function.

Possible Causes:

- Burned Out Bulb: The warning light bulb in the dashboard might be burned out.

- Open Circuit in Wiring: There might be a break in the wire connecting the switch to the warning light.

- Faulty Oil Pressure Switch: The switch might be stuck in the open position, preventing the circuit from completing.

Solutions:

- Check the Bulb: Confirm that the warning light bulb is functional. You might need to remove the instrument cluster to access the bulb.

- Inspect the Wiring: Carefully inspect the wiring harness for any breaks or loose connections. Use a multimeter to check for continuity between the switch and the warning light.

- Test the Switch: Disconnect the wire from the switch and use a jumper wire to connect the wire directly to ground. If the light comes on, the switch is likely faulty and needs replacement.

Real-World Examples

Toyota Camry (1997-2001): A common issue is oil leaks around the oil pressure switch due to age. This can lead to misreadings. Replacing the switch and cleaning the surrounding area often solves the problem.

Honda Civic (2006-2011): Corrosion on the switch terminals is a frequent problem, especially in regions with harsh winters. Regular cleaning and application of dielectric grease can prevent this.

Ford F-150 (2004-2008): Wiring issues due to rodent damage are not uncommon. Inspecting the wiring harness for chewed wires is crucial.

Preventive Measures: Keeping Your Car in Top Condition

Regular maintenance is key to preventing problems with your oil pressure switch and other vital components:

- Regular Oil Changes: Use the correct type and viscosity of oil recommended by your vehicle manufacturer. Clean oil ensures proper lubrication and extends the life of engine components.

- Inspect Regularly: Make it a habit to visually inspect your engine bay regularly for leaks, damage, and corrosion.

- Address Issues Promptly: Don't ignore warning lights or unusual engine noises. Address potential problems as soon as possible to prevent them from escalating into more serious (and costly) repairs.

- Professional Check-ups: Schedule regular check-ups with a qualified mechanic. They can perform more thorough inspections and identify potential issues before they become major problems.

By understanding the function of the 2-wire oil pressure switch and following these maintenance and troubleshooting tips, you can ensure your engine remains properly lubricated and protected from damage.