2003 Honda Element Idle Air Control Valve

The 2003 Honda Element, a vehicle known for its practicality and utilitarian design, utilized an Idle Air Control (IAC) valve to regulate engine idle speed. This article delves into the technical specifications, engineering choices, real-world performance, and long-term implications of the IAC valve system in this specific model.

Technical Specifications and Engineering Choices

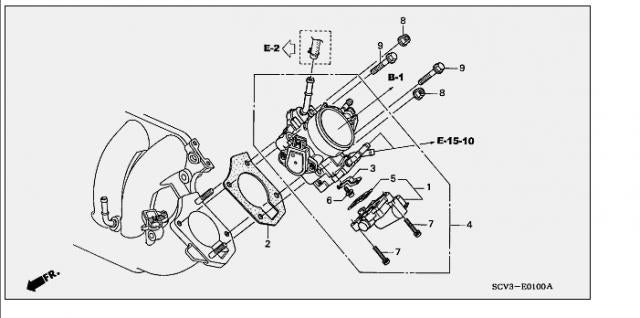

The 2003 Honda Element employs a rotary-type IAC valve, manufactured primarily by Keihin, a well-established Honda supplier. This valve controls the amount of air bypassing the throttle plate when the engine is idling. The Electronic Control Unit (ECU) receives data from various sensors, including the engine coolant temperature sensor (ECT), throttle position sensor (TPS), and vehicle speed sensor (VSS), to determine the appropriate idle speed. Based on this data, the ECU sends a signal to the IAC valve, adjusting its opening to maintain the target RPM.

The rotary design was favored for its relatively simple construction, durability, and ease of integration into the engine management system. The valve typically features a stepper motor that precisely positions a rotary valve element. This element controls the airflow through a bypass passage in the throttle body. The specific resistance values of the IAC valve's windings are critical for proper operation. Deviations from the factory specifications, usually between 20-30 ohms, can indicate a failing or faulty valve.

Real-World Performance and Alternatives

In real-world driving conditions, the IAC valve plays a crucial role in ensuring a smooth and stable idle, particularly during cold starts and when the air conditioning compressor is engaged. A properly functioning IAC valve prevents the engine from stalling or exhibiting rough idle characteristics. A common symptom of a failing IAC valve is a fluctuating or abnormally high idle speed. In some cases, the engine may even stall, especially when coming to a stop.

Alternatives to the rotary IAC valve include linear solenoid-based IAC valves and electronic throttle control (ETC) systems. Linear solenoid valves offer fast response times but can be more susceptible to contamination. ETC systems, also known as drive-by-wire, eliminate the need for a separate IAC valve altogether by directly controlling the throttle plate opening. While ETC systems offer more precise control and integration with other vehicle systems, they are also more complex and expensive to implement. The rotary IAC valve provided a good balance between cost, reliability, and performance for the 2003 Element.

Pros and Cons of the Rotary IAC Valve

Pros:

- Relatively simple and robust design.

- Cost-effective compared to more advanced systems.

- Generally reliable, with a long service life under normal conditions.

Cons:

- Susceptible to carbon buildup and contamination, which can affect performance.

- Requires periodic cleaning to maintain optimal operation.

- Can exhibit slower response times compared to linear solenoid valves.

Reliability Aspects and Maintenance Tips

The reliability of the IAC valve on the 2003 Honda Element is generally good, but it's not immune to failure. The most common cause of failure is carbon buildup inside the valve and throttle body bypass passage. This buildup restricts airflow and prevents the valve from properly regulating idle speed.

Maintenance Tips:

- Regularly clean the throttle body and IAC valve using a throttle body cleaner. It's generally recommended to do this every 30,000 to 50,000 miles.

- Inspect the IAC valve connector for corrosion or damage.

- Use a scan tool to monitor the IAC valve's operating parameters, such as its position and duty cycle.

- When replacing the IAC valve, use a genuine Honda or Keihin part to ensure proper fit and function. Aftermarket parts may not meet the same quality standards and can lead to performance issues.

Troubleshooting a suspect IAC valve can often be done with a multimeter. Checking the resistance of the coil is the first step. Also, check for voltage getting to the valve while the engine is idling. Sometimes a broken wire in the harness will cause issues with IAC functionality.

Future Trends

The trend in the automotive industry is towards more sophisticated engine management systems, including electronic throttle control (ETC) and integrated powertrain control modules. As vehicles become more complex and fuel economy standards become more stringent, the reliance on separate IAC valves is diminishing. Modern vehicles are increasingly using ETC systems to manage idle speed, as well as other functions such as traction control and cruise control.

Forward-Looking Note

The automotive industry is in a period of rapid transformation, driven by technological advancements in areas such as electrification, autonomous driving, and connectivity. While components like the IAC valve may become less prevalent in newer vehicles, understanding their function and limitations remains important for automotive professionals. The knowledge gained from working on older systems like the 2003 Honda Element's IAC valve can provide a valuable foundation for diagnosing and repairing more complex systems in the future. As hybrid and electric vehicles become more common, a solid understanding of fundamental automotive principles will be essential for technicians to adapt and thrive in this evolving landscape. The principles of airflow management, sensor technology, and ECU control, which are evident in the IAC valve system, will continue to be relevant in the development and maintenance of future automotive technologies.