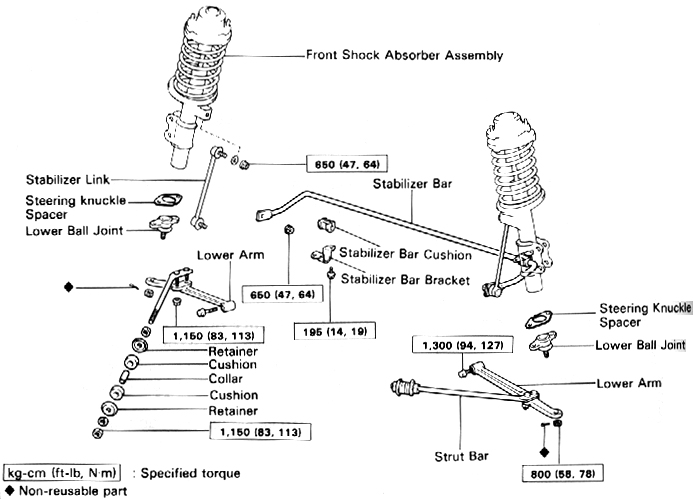

2006 Toyota Camry Front Suspension Diagram

The 2006 Toyota Camry, a cornerstone of reliability and practicality, utilized a MacPherson strut front suspension system. Understanding this system's design, technical specifications, and real-world performance is crucial for automotive professionals involved in its maintenance and repair.

Technical Specifications and Engineering Choices

The front suspension of the 2006 Camry features independent MacPherson struts. Each strut comprises a coil spring surrounding a shock absorber, all housed within a single unit. This design is compact and relatively lightweight, contributing to the Camry's overall fuel efficiency and packaging.

Key components include:

- Lower Control Arm (LCA): A forged steel component connecting the steering knuckle to the vehicle's frame. It allows vertical movement of the wheel while maintaining lateral stability. Bushings at the LCA's mounting points absorb vibrations and allow for controlled movement.

- Steering Knuckle: The pivot point for steering, connecting the strut, LCA, and tie rod end. It houses the wheel bearing and brake assembly.

- Coil Spring: Provides vertical support for the vehicle and absorbs shocks. The spring rate is carefully chosen to balance ride comfort and handling.

- Shock Absorber (Damper): Damps oscillations in the spring, preventing excessive bouncing and ensuring a smooth ride. The shock absorber's damping characteristics are tuned to match the spring rate.

- Stabilizer Bar (Sway Bar): Connects the left and right sides of the suspension, reducing body roll during cornering. It improves handling and stability.

- Strut Mount: Located at the top of the strut, it attaches the strut assembly to the vehicle's body. It incorporates a bearing that allows the strut to pivot during steering.

Toyota chose the MacPherson strut design for several reasons. It's cost-effective, relatively simple to manufacture and assemble, and provides a good balance of ride comfort and handling for a vehicle in this class. Its compactness also allows for a lower hood line and more interior space compared to some other suspension designs.

Real-World Performance and Comparison

The 2006 Camry's front suspension is known for its comfortable ride quality. It effectively absorbs bumps and road imperfections, providing a smooth and quiet driving experience. However, its handling characteristics are not particularly sporty. The focus is on predictability and stability rather than sharp cornering. Body roll is noticeable during aggressive maneuvers, although the stabilizer bar helps to mitigate it.

Compared to a double-wishbone suspension, which is often found in higher-performance vehicles, the MacPherson strut offers less precise control of wheel camber and caster during suspension travel. This can lead to reduced grip and less responsive handling. However, the double-wishbone design is more complex, expensive, and requires more space, making it less suitable for the Camry's target market.

An alternative might have been a multi-link suspension, which offers a better compromise between ride comfort and handling than the MacPherson strut while being more compact than a double-wishbone. However, multi-link systems are generally more expensive and complex than MacPherson struts.

Pros and Cons of MacPherson Strut Suspension

Pros:

- Cost-effective: Lower manufacturing and assembly costs compared to other designs.

- Compact: Requires less space, allowing for more interior volume and a lower hood line.

- Lightweight: Contributes to improved fuel efficiency.

- Good ride comfort: Effectively absorbs bumps and road imperfections.

- Relatively simple to maintain: Fewer components than more complex suspension designs.

Cons:

- Less precise handling: Not as responsive as double-wishbone or multi-link suspensions.

- Limited camber control: Camber changes during suspension travel can reduce grip.

- Higher strut tower: Can impact engine bay layout.

Reliability and Maintenance

The 2006 Camry's front suspension is generally reliable. However, certain components are prone to wear and tear over time, requiring periodic maintenance. Common issues include worn bushings in the lower control arms, leaking shock absorbers, and corroded coil springs. Inspecting these components regularly is crucial for maintaining optimal performance and safety. Look for signs of cracking, tearing, or excessive play in the bushings. Check the shock absorbers for leaks or signs of diminished damping performance. Examine the coil springs for rust or cracks.

Recommended maintenance includes:

- Regular inspection of suspension components (every 12 months or 12,000 miles).

- Replacement of worn bushings and ball joints.

- Replacement of shock absorbers every 50,000 to 75,000 miles.

- Wheel alignment after suspension repairs or tire replacement.

Using quality replacement parts is essential for ensuring long-term reliability and performance. Opt for reputable brands and follow the manufacturer's recommended torque specifications when tightening fasteners.

Future Trends

While the MacPherson strut remains a popular choice for many vehicles, advancements in suspension technology are constantly evolving. Future trends include the increased use of adaptive dampers, air suspension systems, and electronically controlled suspension components. These technologies offer improved ride comfort, handling, and adjustability, allowing vehicles to adapt to different driving conditions. Furthermore, the integration of sensors and control systems is paving the way for semi-active and fully active suspension systems that can proactively adjust damping and ride height in response to road conditions and driver inputs.

Conclusion

The 2006 Toyota Camry's MacPherson strut front suspension represents a well-engineered and cost-effective solution for providing a comfortable and reliable ride. Understanding its design, technical specifications, and maintenance requirements is essential for automotive professionals. As the automotive industry continues to evolve, advancements in suspension technology will undoubtedly lead to further improvements in ride comfort, handling, and safety. A continuous learning approach regarding new technologies is critical to staying ahead in this ever-changing field.