2007 Yukon Denali Air Ride Compressor Fuse

The 2007 GMC Yukon Denali, like many luxury SUVs and trucks of its era, offered a sophisticated ride quality thanks to its auto-leveling rear air suspension. This system uses an air compressor to inflate air springs, maintaining a level ride height regardless of load. A critical component in this system is the fuse protecting the air ride compressor circuit. A blown fuse here can disable the entire system, leading to a saggy rear end and a noticeably harsher ride. This article will delve into the specifics of this fuse, explaining its function, how to identify a blown one, and what steps you can take to diagnose and potentially resolve the issue.

Understanding the Air Ride Compressor System

Before diving into the fuse itself, let's briefly cover how the air ride compressor system works. Think of it as a miniature air pump dedicated to your rear suspension. The system includes:

- Air Compressor: The heart of the system, it compresses air and pumps it into the air springs.

- Air Springs (or Air Shocks): These replace traditional coil springs at the rear wheels. They are essentially inflatable bags that provide support.

- Ride Height Sensors: These sensors monitor the distance between the chassis and the axle. They send signals to the control module indicating whether the vehicle is level.

- Electronic Control Module (ECM): This computer brain receives signals from the ride height sensors and commands the compressor to inflate or deflate the air springs as needed.

- Air Lines: These hoses connect the compressor to the air springs and other components.

- Vent Solenoid: Allows air to be released from the system when the vehicle is too high or when lowering is desired.

When you load up the back of your Denali with cargo, the ride height sensors detect the sag. The ECM then activates the air compressor to inflate the air springs, raising the rear of the vehicle back to the proper level. This keeps the ride smooth and prevents the headlights from blinding oncoming traffic. This is similar in concept to the systems found in some Land Rovers or older Lincoln Navigators, though the specific components and programming may differ. The 2007 Denali's system is relatively simple compared to some more modern air suspension systems that actively dampen and adjust for various road conditions.

The Air Ride Compressor Fuse: Location and Function

The air ride compressor is a high-current device, meaning it draws a significant amount of electricity when operating. To protect the electrical system from overload and potential damage, a fuse is placed in the circuit. If the compressor draws too much current (due to a malfunction, blockage, or other issue), the fuse blows, interrupting the circuit and preventing further damage.

The location of the air ride compressor fuse in a 2007 Yukon Denali is typically in the underhood fuse box. This fuse box is usually located on the driver's side, near the engine compartment's firewall. The specific fuse location is critical information and is usually detailed in the owner's manual or on a diagram inside the fuse box cover. Look for a fuse labeled "Air Suspension," "ELEC SUSP," "Compressor," or something similar. The amperage rating of the fuse is also important and is usually printed on the fuse itself (e.g., 25A, 30A). Never replace a fuse with a higher amperage fuse, as this can bypass the intended safety mechanism and potentially cause a fire or other serious electrical damage. Using the wrong amperage fuse is akin to using the wrong oil filter - it might fit, but it won't protect the system as intended.

It is vital to consult your 2007 Yukon Denali's owner's manual or a reliable service manual to confirm the *exact* fuse location and amperage. Fuse box layouts can vary slightly even within the same model year, depending on options and trim levels.

Symptoms of a Blown Air Ride Compressor Fuse

The most obvious symptom of a blown air ride compressor fuse is a malfunctioning air suspension system. This often manifests as:

- A saggy rear end: The rear of the vehicle sits noticeably lower than the front, especially when loaded with cargo or passengers.

- A rough or bouncy ride: Without the air springs properly inflated, the ride quality becomes significantly harsher.

- The "Service Ride Control" message: The driver information center (DIC) may display this message, indicating a problem with the air suspension system.

- The air compressor not running: You may not hear the compressor activate when starting the vehicle or loading the rear.

However, these symptoms can also be caused by other issues within the air suspension system, such as a faulty compressor, leaking air springs, a malfunctioning ride height sensor, or a problem with the ECM. Therefore, simply replacing the fuse without further investigation is not always the best approach.

Diagnosing a Blown Fuse and its Cause

Before replacing the fuse, it's essential to determine why it blew in the first place. Simply replacing it might result in the new fuse blowing immediately or shortly after, indicating an underlying problem that needs to be addressed.

Here's a step-by-step approach to diagnosing the issue:

- Visual Inspection: Remove the fuse and visually inspect it. A blown fuse will typically have a broken filament inside the clear plastic housing.

- Continuity Test: Use a multimeter to perform a continuity test on the fuse. A good fuse will have continuity (the meter will indicate a closed circuit), while a blown fuse will not.

- Check for Obvious Damage: Inspect the air compressor, air lines, and air springs for any signs of damage, leaks, or corrosion. A leak in the system can cause the compressor to work overtime, leading to a blown fuse.

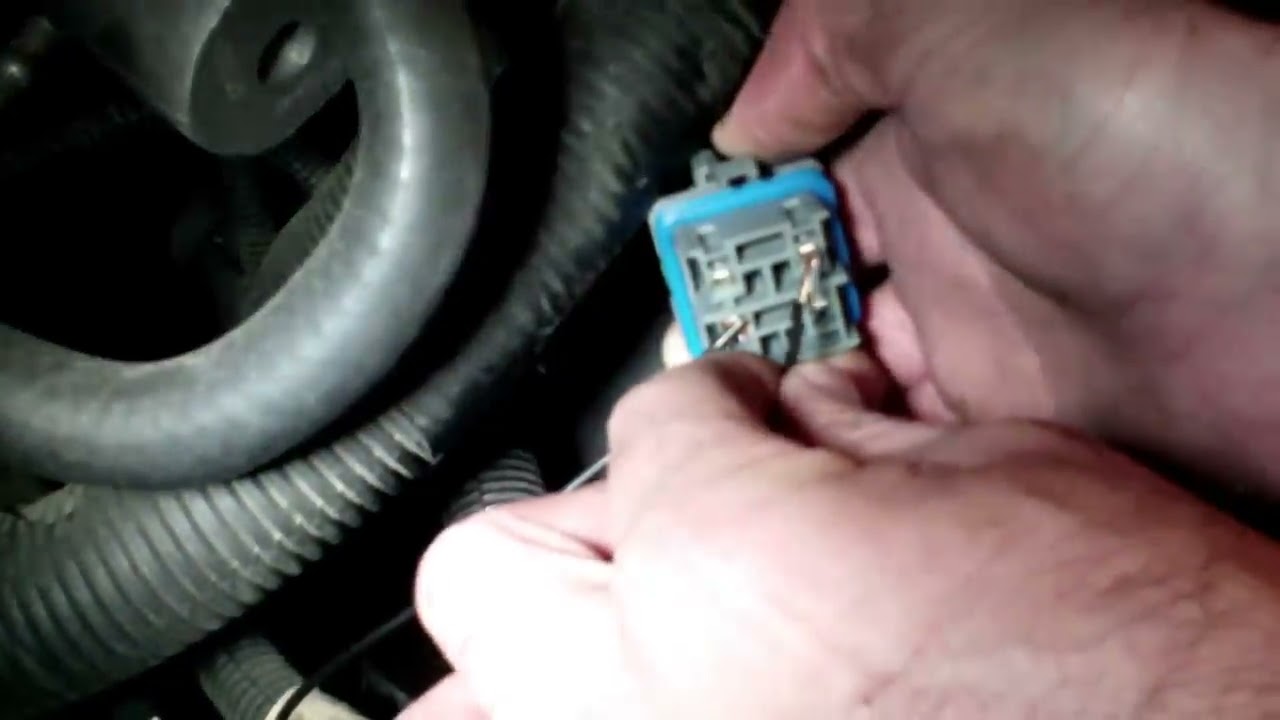

- Test the Compressor Relay: The air compressor is often controlled by a relay. A faulty relay can cause the compressor to run continuously or intermittently, potentially overloading the circuit. The relay is usually located in the same fuse box as the fuse. You can test the relay by swapping it with a known good relay (of the same type) or by using a multimeter to check its operation.

- Check the Compressor Wiring: Inspect the wiring harness leading to the air compressor for any signs of damage, such as frayed wires, loose connections, or corrosion. A short circuit in the wiring can cause the fuse to blow.

If you find any of these issues, address them before replacing the fuse. For example, if you find a leaking air spring, replace it. If you find a damaged wire, repair it. Only then should you replace the fuse and test the system.

Practical Takeaways

Understanding the air ride compressor fuse in your 2007 Yukon Denali is crucial for maintaining a smooth and comfortable ride. Here are some practical takeaways:

- Know the Fuse Location: Familiarize yourself with the location and amperage of the air ride compressor fuse in your owner's manual.

- Carry Spare Fuses: Keep a set of spare fuses in your vehicle, including the correct amperage for the air ride compressor.

- Diagnose Before Replacing: Don't just replace a blown fuse without investigating the underlying cause.

- Address Underlying Issues: Repair any leaks, damaged wiring, or faulty components before replacing the fuse.

- Consult a Professional: If you're not comfortable working on electrical systems or air suspension systems, consult a qualified mechanic. An experienced technician can diagnose and repair the issue quickly and effectively.

By following these guidelines, you can keep your 2007 Yukon Denali's air suspension system working properly and enjoy the comfortable ride it was designed to provide. Remember, preventative maintenance, like checking the air lines for cracks or wear, can save you from bigger headaches down the road.