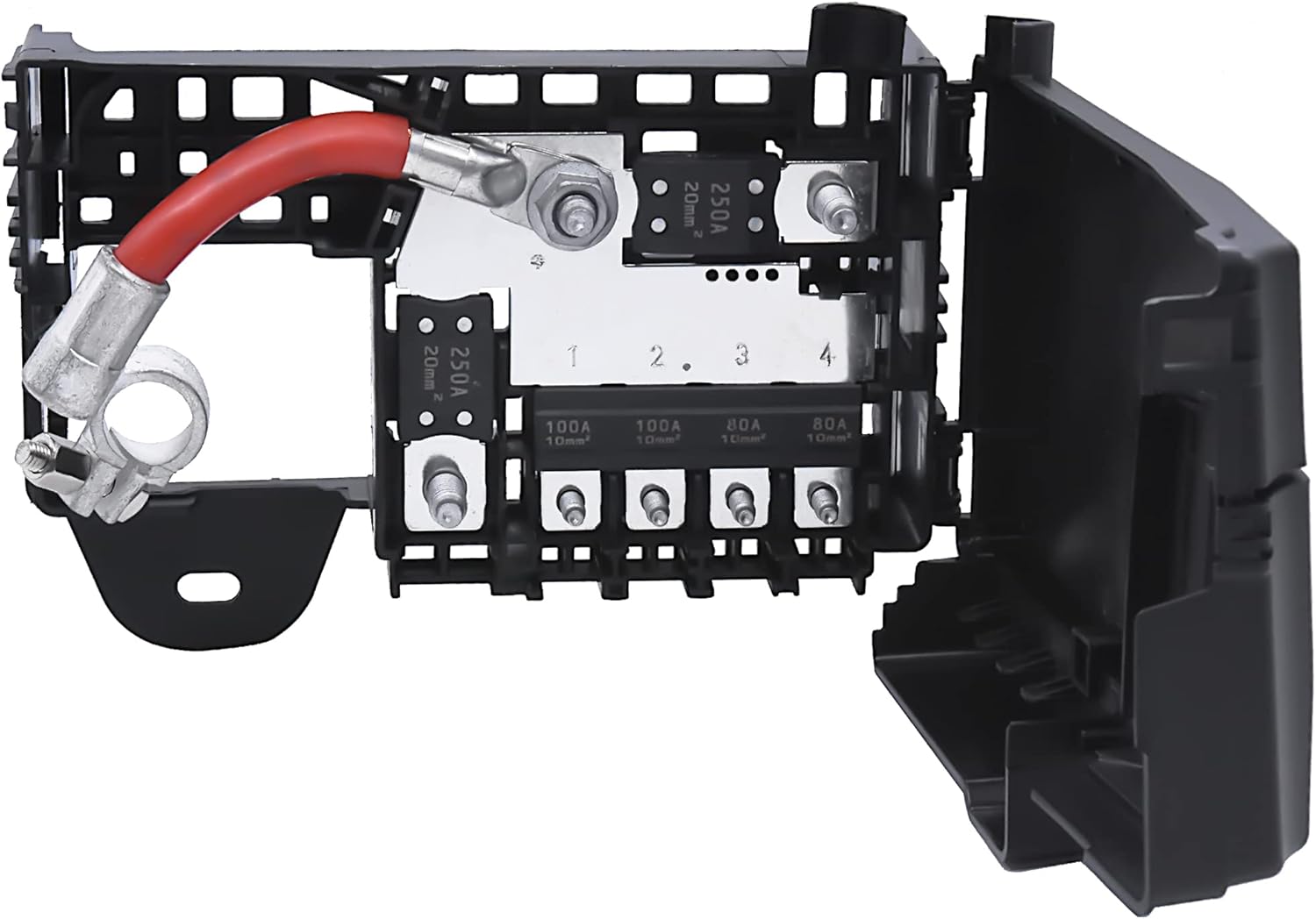

2012 Chevy Cruze Fuse Box Battery Terminal

Alright, let's talk about the fuse box battery terminal on your 2012 Chevy Cruze. This is a critical area, often overlooked but essential for proper electrical function. Understanding its role, potential issues, and how to maintain it can save you a lot of headaches down the road. We're going to dive deep, so buckle up!

Location and Function

The fuse box we're focusing on is typically located in the engine compartment, near the battery. You'll recognize it as a black plastic enclosure, usually rectangular, with a latch or clip securing the lid. Inside, you'll find a collection of fuses and relays, each protecting a specific circuit within your car's electrical system. The battery terminal we're discussing is the point where the main positive (12V+) cable from your battery connects directly to this fuse box. It's the primary power distribution hub for many of the car's systems.

Its function is simple but crucial: to deliver power from the battery to the fuse box, which then distributes that power to individual circuits. Think of it as the main artery delivering blood (electricity) to the rest of the body (the car's electrical system). Without a clean, secure connection at this terminal, you'll experience a range of electrical problems.

Common Problems and Symptoms

Several issues can arise with the fuse box battery terminal, impacting the overall performance of your Cruze. Here are some of the most common problems:

Corrosion

Corrosion is the most frequent culprit. Battery acid, moisture, and exposure to the elements can lead to corrosion build-up on the terminal and the connecting cable. This corrosion acts as an insulator, restricting the flow of electricity. The electrical resistance increases. Symptoms of corrosion include:

- Dim headlights: Reduced voltage at the terminal translates to reduced voltage at the headlights.

- Slow cranking or no-start condition: The starter motor needs a strong surge of power to crank the engine. Corrosion can prevent this.

- Intermittent electrical problems: The connection may be good sometimes and bad others, leading to unpredictable issues like flickering lights, radio cutting out, or even engine stalling.

- Erratic gauge readings: Sensors rely on a stable voltage supply. A corroded terminal can cause fluctuations in voltage, leading to inaccurate gauge readings.

Loose Connection

Over time, the nut or bolt securing the battery cable to the fuse box terminal can loosen due to vibration or temperature changes. This creates a loose connection, which can cause similar symptoms to corrosion.

Damaged Terminal or Cable

Physical damage to the terminal itself, such as cracks or breaks, can also disrupt the electrical connection. Similarly, a damaged battery cable (frayed wires, corroded connectors) can hinder the flow of current. Sometimes, during a jump-start procedure the wires leading to the fuse box terminal can be damaged.

Voltage Drop

A significant voltage drop across the terminal is a key indicator of a problem. Use a multimeter to measure the voltage at the battery terminals and then at the fuse box battery terminal while the engine is running. A substantial difference (more than 0.5 volts) indicates excessive resistance, often due to corrosion or a loose connection. This voltage drop can starve electrical components of the power they need to function correctly. The acceptable voltage drop is dependent on circuit load and wiring lengths. It's important to consult the vehicle's service manual.

Troubleshooting and Repair

Here's a step-by-step guide to troubleshooting and repairing the fuse box battery terminal on your 2012 Cruze:

- Safety First! Disconnect the negative (-) battery cable before working on any electrical components. Use a wrench to loosen the clamp on the negative terminal and carefully remove the cable. Secure it away from the battery to prevent accidental contact.

- Visual Inspection: Carefully examine the terminal, the connecting cable, and the surrounding area for signs of corrosion, damage, or looseness. Look for white or greenish powder (corrosion) on the terminal and cable ends. Check for any cracks or breaks in the terminal housing.

- Cleaning the Terminal: If you find corrosion, use a battery terminal cleaner brush (available at most auto parts stores) to thoroughly clean the terminal and the cable connector. You can also use a mixture of baking soda and water to neutralize the acid. Apply the paste, let it fizz, then scrub with a brush and rinse thoroughly with water. Ensure the area is completely dry before reassembling.

- Tightening the Connection: If the connection is loose, tighten the nut or bolt securing the battery cable to the terminal. Use the correct size wrench and avoid overtightening, as this can damage the terminal. The specified torque value can be found in the service manual.

- Voltage Drop Test: Reconnect the negative battery cable. Start the engine and let it idle. Use a multimeter to measure the voltage at the battery terminals and then at the fuse box battery terminal. A significant difference indicates a problem.

- Cable Inspection and Replacement: If cleaning and tightening the connection doesn't resolve the issue, inspect the battery cable for damage. Look for frayed wires, corroded connectors, or signs of heat damage. If the cable is damaged, replace it with a new one of the correct gauge and length. Consult your service manual for the correct wire gauge.

- Terminal Replacement: In severe cases, the terminal itself may be damaged beyond repair. You can replace the entire fuse box assembly or, in some cases, just the terminal itself. Replacing just the terminal may require some soldering or crimping skills, depending on the design.

- Applying Dielectric Grease: After cleaning or replacing the terminal, apply a thin coat of dielectric grease to the terminal and the cable connector. This grease helps to prevent corrosion and maintain a good electrical connection.

Preventative Maintenance

To prevent problems with your fuse box battery terminal, incorporate these preventative maintenance measures:

- Regular Inspection: Inspect the terminal and cable for corrosion or looseness every six months.

- Cleaning: Clean the terminal as needed to remove any corrosion buildup.

- Applying Dielectric Grease: Apply a thin coat of dielectric grease after each cleaning.

- Check Battery Health: A weak or failing battery can put extra strain on the electrical system, potentially contributing to corrosion and other issues. Have your battery tested regularly.

By understanding the function of the fuse box battery terminal, recognizing common problems, and implementing these troubleshooting and maintenance tips, you can keep your 2012 Chevy Cruze running smoothly and avoid unexpected electrical issues. Remember, if you're uncomfortable performing any of these tasks, it's always best to consult with a qualified mechanic.