2015 Gmc Yukon 6.2 Head Bolt Torque Specs

The 2015 GMC Yukon Denali, with its potent 6.2L EcoTec3 L86 V8 engine, is a popular choice for those needing a blend of power, luxury, and utility. When undertaking cylinder head work on this engine, adhering to the correct head bolt torque specifications and tightening sequence is paramount for ensuring proper sealing and preventing catastrophic engine damage. This article delves into the specific torque specs and procedures for the 6.2L L86 engine found in the 2015 Yukon Denali.

Head Bolt Identification

Before diving into the torque sequence, it's crucial to identify the different types of head bolts used in the L86 engine. The 2015 Yukon 6.2L utilizes torque-to-yield (TTY) head bolts, which are designed to stretch upon tightening. These bolts are not reusable and must be replaced with new ones each time the cylinder heads are removed. Typically, you'll encounter two different lengths of head bolts. Ensure you keep track of their original positions during removal to reinstall the correct length in the corresponding location.

Required Tools

To accurately torque the head bolts, you will need the following tools:

- A reliable torque wrench capable of measuring in Newton-meters (Nm) and degree increments. Digital torque wrenches are highly recommended for accuracy.

- A degree wheel or digital angle gauge to measure the final angle of rotation.

- A set of sockets, including a six-point socket of the correct size for the head bolts. Using a six-point socket minimizes the risk of rounding off the bolt heads.

- New head bolts specifically designed for the L86 engine. Using aftermarket or incorrect bolts can lead to engine failure.

- Engine oil or assembly lube to lubricate the bolt threads and under the bolt heads.

Torque Specifications and Sequence

The following torque specifications and tightening sequence are crucial for achieving proper cylinder head sealing on the 2015 GMC Yukon 6.2L L86 engine. This information is generally applicable to other vehicles using the same engine, but always verify with a reputable source like the service manual.

Important: Ensure the cylinder head and block mating surfaces are clean and free of debris before installation.

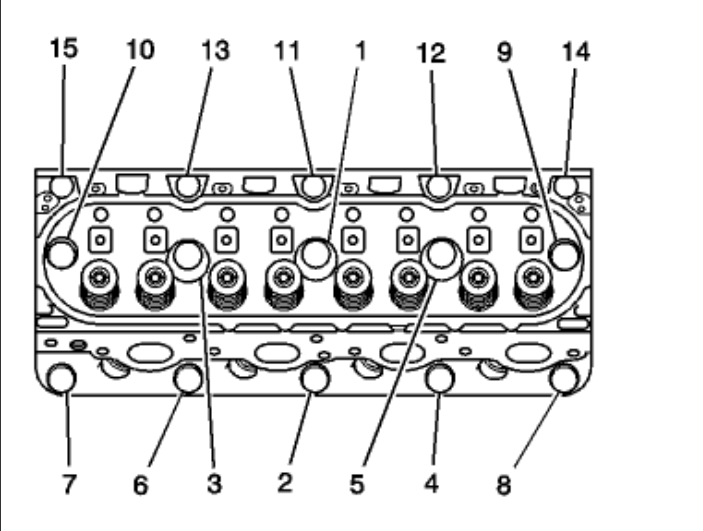

The tightening sequence is as follows (refer to a diagram for the numbering of the head bolts, typically starting from the center and working outwards):

- Stage 1: Torque all head bolts in sequence to 22 Nm (16 lb-ft).

- Stage 2: Torque all head bolts in sequence to 47 Nm (35 lb-ft).

- Stage 3: Using the degree wheel or angle gauge, tighten all head bolts in sequence an additional 70 degrees.

- Stage 4: Tighten all head bolts in sequence an additional 50 degrees.

Note: The angular tightening is critical for TTY bolts. Do not skip or deviate from these steps. A slight variation in the degree of rotation can significantly impact head gasket sealing and longevity. Furthermore, always double-check your work to ensure each bolt has been tightened according to the specified sequence and torque values.

Lubrication

Proper lubrication is essential for accurate torque readings and prevents galling of the bolt threads. Apply a thin coat of engine oil or assembly lube to the threads and under the heads of all new head bolts before installation. This ensures consistent friction and accurate tensioning during the tightening process.

Post-Installation Checks

After completing the head bolt tightening procedure, it's recommended to allow the engine to sit for a short period before adding coolant and starting the engine. This allows the head gasket to settle and conform to the mating surfaces. Once the engine is running, closely monitor for any signs of leaks or overheating. Retorquing the head bolts is not recommended with TTY bolts; however, regularly checking for coolant leaks is essential during the break-in period.

Disclaimer

This information is provided as a guideline and should not be considered a substitute for consulting the official 2015 GMC Yukon service manual. Always refer to the official service manual for the most accurate and up-to-date torque specifications and procedures. Improper installation of cylinder heads can result in severe engine damage. If you are not comfortable performing this procedure, it is recommended to seek assistance from a qualified automotive technician.