2015 Ram 1500 Rear Differential Fluid Type

The venerable 2015 Ram 1500, a stalwart of the American road, might seem an unlikely starting point for a discussion about the future of mobility. After all, we’re talking about the fluid lubricating its rear differential – a component seemingly worlds away from the self-driving electric vehicles and hyper-connected transportation networks that dominate headlines. But even something as fundamental as rear differential fluid highlights the profound changes sweeping the automotive industry. Let's delve into how technological advancements are reshaping our expectations for performance, efficiency, and sustainability, even at the level of seemingly mundane maintenance tasks.

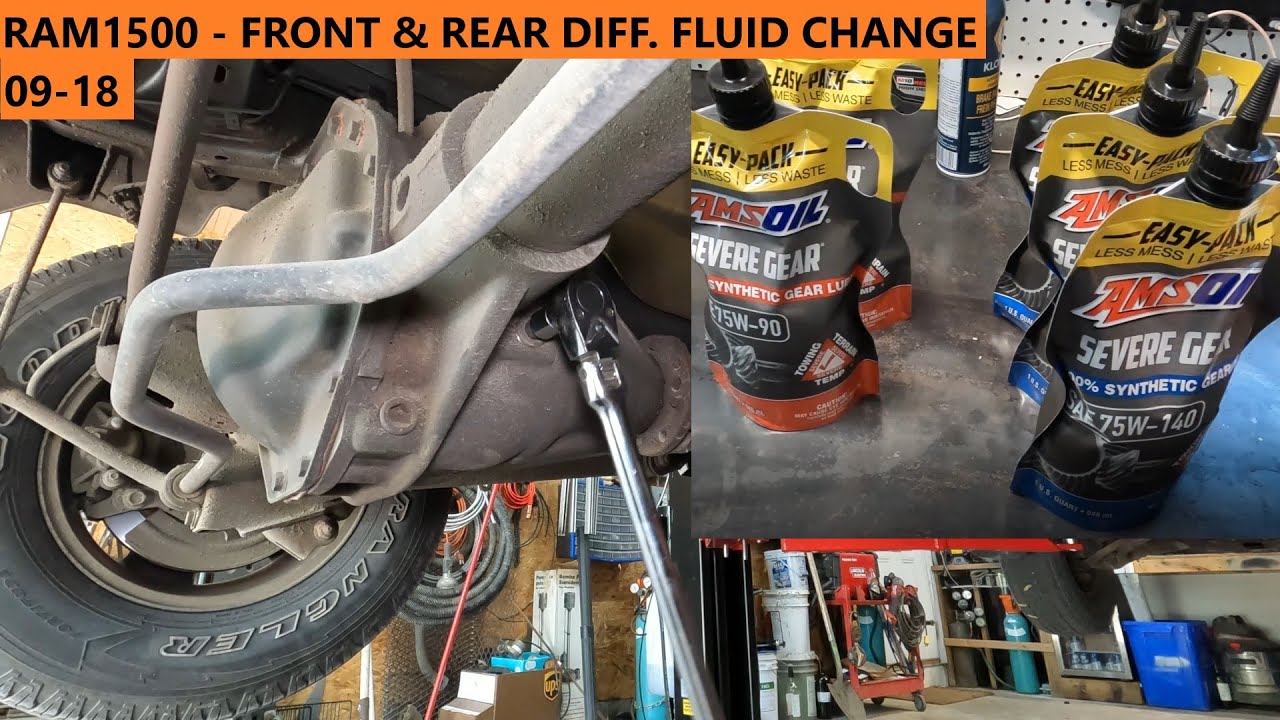

For the 2015 Ram 1500, the specified rear differential fluid type likely revolves around a synthetic gear oil meeting specific viscosity and performance standards (e.g., SAE 75W-90, API GL-5). The goal is to ensure proper lubrication, heat dissipation, and protection against wear and tear, extending the life of the differential. But even here, innovation is creeping in. Advances in fluid chemistry are leading to more durable, higher-performance lubricants that can further reduce friction, improve fuel economy (albeit marginally), and withstand extreme operating conditions. These advanced fluids often boast longer service intervals, reducing the frequency of maintenance and contributing to lower overall ownership costs.

The Electric Revolution and its Impact

The rise of electric vehicles (EVs) is arguably the most significant disruptor in the automotive landscape. While the 2015 Ram 1500 is firmly rooted in the internal combustion engine (ICE) era, the future of pickup trucks – and all vehicles – is increasingly electric. EVs, of course, don’t have traditional rear differentials in the same way. Instead, they utilize gearboxes and potentially single-speed or multi-speed transmissions integrated with the electric motor. This shift necessitates entirely different types of lubricants, primarily focused on cooling the electric motor and managing the high-speed rotational forces within the transmission. These fluids need to be electrically insulating and compatible with the materials used in electric motors and power electronics.

However, the principles of reducing friction, managing heat, and extending component life remain paramount. We can expect to see continued innovation in EV transmission fluids, focusing on improving thermal conductivity, reducing copper corrosion (a concern with electric motors), and extending the lifespan of the fluid to match the extended maintenance intervals typical of EVs. Furthermore, smart fluid monitoring systems, incorporating sensors to detect fluid degradation, contamination, and temperature fluctuations, will become increasingly prevalent. This allows for proactive maintenance, preventing potential failures and maximizing the lifespan of critical components.

Hybrid Systems: A Bridge to the Future

Hybrid systems, including plug-in hybrids, represent a crucial bridge between the ICE-powered past and the all-electric future. The 2015 Ram 1500 actually saw some early attempts at hybrid technology, albeit with limited success. Modern hybrid systems, however, are far more sophisticated. In these vehicles, the rear differential (or its equivalent in an EV architecture) still plays a role, although its operational demands may differ depending on the configuration. The integration of electric motors into the drivetrain can reduce the load on the rear differential in certain driving scenarios, potentially extending its lifespan. Conversely, the increased complexity of the drivetrain requires careful optimization of lubrication systems to ensure compatibility and optimal performance.

The challenge for hybrid systems lies in managing the interplay between the ICE and electric motor. Lubricants must be compatible with both types of powertrains and withstand the variable operating conditions that characterize hybrid driving. This necessitates advanced fluid formulations that can handle the thermal stresses and chemical interactions arising from the combined operation of these systems.

Smart Automotive Solutions and the Connected Car

Beyond powertrain technology, the rise of smart automotive solutions and the connected car is also influencing the future of lubrication. Real-time data from vehicle sensors can be used to monitor the condition of the rear differential fluid (or its EV equivalent) and predict potential failures. This data can be integrated with cloud-based diagnostic platforms, allowing for proactive maintenance scheduling and preventative repairs. Imagine a system that automatically alerts the driver (or fleet manager) when the fluid is nearing the end of its service life, recommending a specific type of replacement fluid based on driving conditions and vehicle usage patterns. This level of precision and personalization will become increasingly common in the future.

Furthermore, the connected car enables over-the-air (OTA) updates to vehicle control software, which can optimize the operation of the drivetrain and lubrication systems based on real-world data. For example, the vehicle could adjust the torque distribution to the rear wheels to minimize stress on the differential, or it could alter the cooling strategy to prevent overheating in extreme conditions. Data-driven optimization is the key to unlocking the full potential of these advanced technologies.

Challenges and Opportunities

While the future of mobility is undoubtedly exciting, it's important to acknowledge the challenges that lie ahead. The transition to EVs requires significant investment in infrastructure, battery technology, and manufacturing capacity. The development of advanced lubricants and fluid management systems also requires ongoing research and development. Moreover, the increasing complexity of vehicle systems necessitates a highly skilled workforce capable of diagnosing and repairing these technologies.

Despite these challenges, the opportunities are immense. The shift to sustainable transportation promises cleaner air, reduced greenhouse gas emissions, and a more resilient energy future. The development of advanced automotive technologies will create new jobs and drive economic growth. And the convergence of transportation, connectivity, and data analytics will revolutionize the way we move people and goods.

The 2015 Ram 1500, a symbol of traditional automotive engineering, serves as a reminder of how far we've come and how far we still have to go. Even the seemingly mundane task of changing rear differential fluid highlights the profound changes transforming the automotive industry. As we look to the future, we can envision a world where vehicles are not just modes of transportation, but intelligent, connected, and sustainable extensions of our lives. A future where even the humble lubricant plays a vital role in powering a cleaner, more efficient, and more connected world. The future of mobility is not just about the destination; it's about the journey, and even the fluids that make that journey possible.