2015 Silverado 4.3 Head Bolt Torque Specs

Alright, let's talk about the head bolt torque specs for your 2015 Silverado with the 4.3L V6 engine (LV1). This is a crucial step during any cylinder head replacement or gasket work, and getting it wrong can lead to a host of problems, from coolant leaks and compression loss to catastrophic engine damage. I'm going to walk you through the process, the numbers, and the 'why' behind it all. I'm assuming you're comfortable with basic automotive procedures like removing and installing cylinder heads. If not, stop now and consult a repair manual!

Why Torque Matters

Before we dive into the numbers, let's understand torque. Torque, in this context, is the rotational force applied to the bolt, essentially how tightly you're tightening it. The specified torque is designed to create a specific clamping force between the cylinder head and the engine block. This clamping force is what seals the combustion chamber, coolant passages, and oil passages. If the clamping force is too low, you'll get leaks and combustion leaks. If it's too high, you risk damaging the head, block, or even snapping the bolt. Think Goldilocks – it has to be just right.

The 4.3L LV1 uses what are called Torque-to-Yield (TTY) bolts. These bolts are designed to stretch a specific amount when tightened. They actually *yield* – meaning they undergo permanent deformation – when torqued to the correct specification. This is critical because it provides a more consistent and accurate clamping force than simply tightening to a fixed torque value alone. This is because variations in thread friction can significantly affect the clamping force if relying only on torque.

The Torque Sequence: Step-by-Step

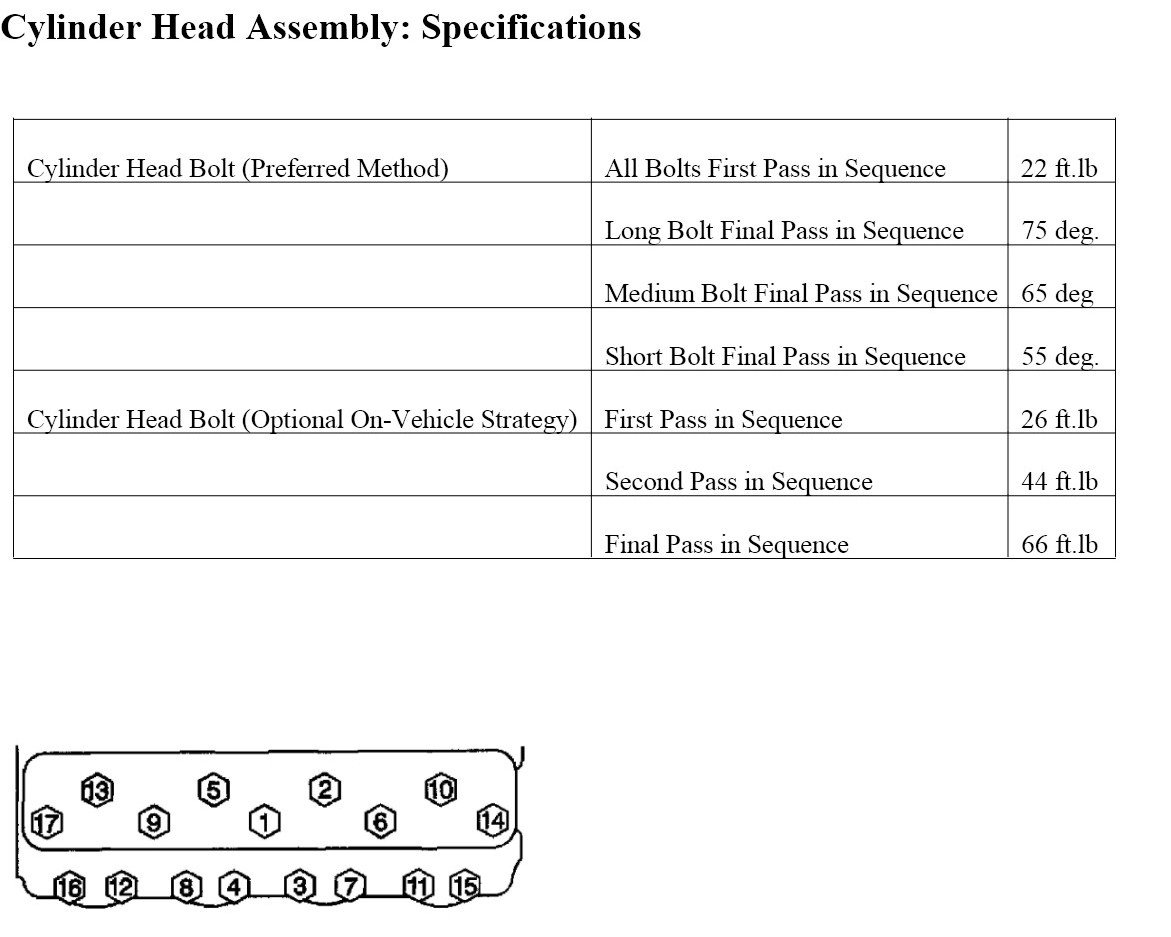

The correct torque sequence is just as important as the torque values themselves. The sequence distributes the clamping force evenly across the head, preventing warping and ensuring a proper seal. The sequence for the 2015 Silverado 4.3L is a multi-step process:

- Visual Inspection: Before you even think about tightening, inspect the head bolts. Are the threads clean and undamaged? Are the bolt heads in good condition? Replace any suspect bolts. Also, make sure the threads in the block are clean. Use a thread chaser (not a tap!) to clean any debris.

- Lubrication: This is absolutely essential. You MUST lubricate the bolt threads and under the bolt head with clean engine oil (SAE 30 is fine). The friction during tightening dramatically affects the final clamping force. Dry threads will give you a false torque reading.

- Initial Torque: Torque all bolts in the sequence to 22 lb-ft (30 Nm). This step ensures the head is seated evenly on the block.

- Angle Tightening: This is where the TTY nature of the bolts comes into play. After the initial torque, you need to turn the bolts a specific angle. The specification for the 4.3L LV1 is to turn each bolt an additional 90 degrees. Use an angle gauge for accurate measurement. These are inexpensive and readily available at auto parts stores.

- Final Angle Tightening: After the first 90-degree turn, turn each bolt another 70 degrees, using the angle gauge.

Here's a summary of the torque specifications:

Step 1: Torque to 22 lb-ft (30 Nm)

Step 2: Turn 90 degrees

Step 3: Turn 70 degrees

Torque Sequence:

Looking at the engine from the front (accessory drive side), the cylinder head bolts should be tightened in the following sequence. This is crucial for even clamping and to avoid warping the head.

Let's assume the cylinders on the driver's side are 1, 3, and 5, and the cylinders on the passenger side are 2, 4, and 6. The front of the engine is the side with the pulleys and belts.

The torque sequence is as follows (this is a simplified representation, refer to a repair manual for an accurate diagram):

- Center Bolt (closest to the intake manifold, near cylinder 3)

- Center Bolt (closest to the intake manifold, near cylinder 4)

- Next Bolt Outward (driver's side, towards exhaust manifold)

- Next Bolt Outward (passenger's side, towards exhaust manifold)

- Outermost Bolt (driver's side, nearest cylinder 1)

- Outermost Bolt (passenger's side, nearest cylinder 6)

- Other Bolt Nearest Cylinder 1

- Other Bolt Nearest Cylinder 6

- Bolt Nearest Cylinder 5

- Bolt Nearest Cylinder 2

Important Notes:

- Always use a calibrated torque wrench. A cheap or inaccurate torque wrench is worse than no torque wrench at all.

- Replace TTY bolts. TTY bolts are designed to be used only once. Once they've been stretched, they won't provide the correct clamping force if reused. Always use new head bolts when reinstalling the cylinder heads.

- Double-check your work. After completing the torque sequence, it's a good idea to go back and double-check each bolt to ensure you didn't miss one.

- Follow the manufacturer's instructions. The information here is a guide. Always refer to the official GM service manual for your specific vehicle and engine. Specifications can change even within the same model year.

What Happens if You Get it Wrong?

I mentioned the potential problems earlier, but let's delve a little deeper:

- Undertightening: This leads to insufficient clamping force. You'll likely experience coolant leaks, oil leaks, and, worst of all, combustion leaks. Combustion leaks can erode the head gasket, damage the cylinder head and block, and cause poor engine performance.

- Overtightening: This can damage the threads in the block, stretch or break the head bolts, and warp the cylinder head. A warped head will never seal properly, even with a new gasket. Snapped bolts are obviously a major headache to extract.

Final Thoughts

Torquing head bolts correctly is one of the most critical steps in rebuilding an engine. Take your time, pay attention to detail, and follow the specified sequence and torque values. If you're unsure about any part of the process, consult a qualified mechanic. A little extra effort upfront can save you a lot of headaches and expensive repairs down the road. Good luck!