40 Series Torque Converter Belt Size Chart

The 40 series torque converter is a staple in the world of small engine applications, powering everything from go-karts and mini bikes to ATVs and even some industrial equipment. A crucial component of its operation is the torque converter belt, responsible for transmitting power from the engine to the driven unit. Choosing the correct belt size is paramount for optimal performance, longevity, and safety. Using the wrong size can lead to belt slippage, premature wear, and even damage to the entire torque converter system.

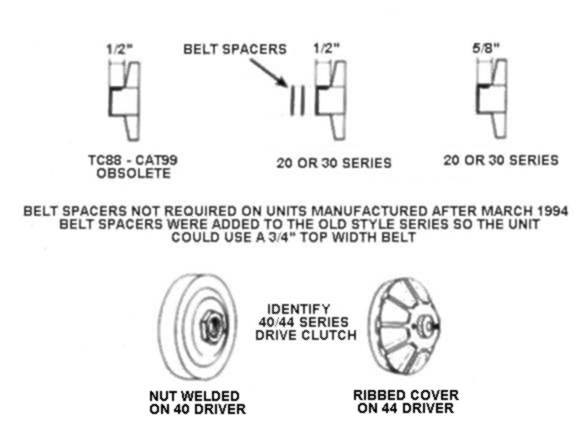

Understanding the 40 Series Torque Converter System

Before diving into belt sizes, let's briefly recap what a 40 series torque converter does. Unlike a traditional clutch system, a torque converter provides a variable drive ratio, allowing the engine to operate within its optimal power band regardless of the vehicle's speed. This is achieved through a system of pulleys (or sheaves) and a belt. The driver pulley is connected to the engine's crankshaft, and the driven pulley transmits power to the axle or transmission. As engine speed increases, the driver pulley closes, effectively increasing the drive ratio. The opposite happens on the driven pulley, opening to accommodate the changing belt position. This seamless shifting allows for smoother acceleration and improved performance, especially at lower speeds.

The 40 series typically handles engines ranging from 8 to 18 horsepower, making it a popular choice for various applications. However, within the 40 series, there can be slight variations depending on the manufacturer and specific model. Always consult the manufacturer's specifications for your particular unit.

The Importance of Belt Size

A torque converter belt isn't just a simple drive belt; it's specifically designed to withstand the stresses and friction inherent in a torque converter system. Using a generic V-belt from an automotive parts store is a recipe for disaster. The 40 series belt is wider and often made from a more robust compound to handle the heat and tension. Proper belt tension is critical. Too loose, and you'll experience excessive slippage and poor performance. Too tight, and you'll overload the bearings and potentially damage the pulleys and belt.

40 Series Torque Converter Belt Size Chart: A Starting Point

While exact dimensions can vary slightly between manufacturers (such as Comet, Manco, or Yerf-Dog), the most common 40 series belt size falls within the following approximate range. Always double-check with your specific torque converter documentation for the most accurate measurement:

- Belt Top Width: Typically around 3/4" (0.75 inches) or 19mm.

- Belt Length (Outside Circumference): This is the critical measurement that varies depending on the center-to-center distance between the engine and the driven unit. Common lengths include (but are not limited to):

- 40 Series Belt 203581: Approximate length of 35 1/8" (35.125 inches)

- 40 Series Belt 203589: Approximate length of 35 3/4" (35.75 inches)

- Other common sizes: 34", 36", 37", 38"

- Belt Angle: The angle of the V shape, crucial for proper engagement with the pulleys. Generally, 28-30 degrees.

Disclaimer: These dimensions are approximate and should not be used as a definitive guide. Always verify the correct belt size for your specific torque converter model before purchasing or installing a new belt.

Finding the Right Belt for Your Application

The best way to determine the correct belt size is to consult the owner's manual or the manufacturer's website for your specific go-kart, mini bike, or other application. If that information is unavailable, you can use the following methods:

- Measure the Old Belt: If you have the old belt, carefully measure its outside circumference using a flexible measuring tape. Ensure the belt is not excessively worn or stretched before measuring.

- Measure Center-to-Center Distance: Measure the distance between the center of the engine's crankshaft and the center of the driven unit's shaft. Use this measurement to consult a belt size chart specific to your torque converter brand and model. Most charts will provide a recommended belt length based on this distance.

- Consult a Professional: If you are unsure about the correct belt size, consult a qualified mechanic or torque converter specialist. They can help you identify the correct belt based on your application and measurements.

Real-World Examples and Troubleshooting

Example 1: Go-Kart with a Comet 40 Series: A common scenario involves a go-kart with a Comet 40 series torque converter. After replacing the engine, the owner notices significant belt slippage. Upon inspection, it's discovered that the new engine is slightly further away from the axle than the old one. The solution? Increase the belt length by 1-2 inches to accommodate the increased center-to-center distance.

Example 2: Mini Bike with a Manco 40 Series: A mini bike owner experiences premature belt wear. They've been using a generic V-belt instead of a proper 40 series belt. Switching to a dedicated 40 series belt with the correct width and angle significantly extends the belt's lifespan and improves performance.

Troubleshooting Tip: If you experience belt slippage even with the correct belt size, check for worn pulleys, proper engine alignment, and adequate belt tension. These factors can all contribute to poor torque converter performance.

Conclusion

Selecting the correct 40 series torque converter belt is crucial for maximizing performance and longevity. By understanding the importance of belt size, consulting manufacturer specifications, and utilizing accurate measurement techniques, you can ensure your small engine application runs smoothly and efficiently. Always prioritize using a dedicated 40 series belt designed for the specific demands of torque converter systems.