Air Compressor Service And Repair Near Me

For the professional mechanic, the weekend hobbyist, or even the dedicated DIYer, a functioning air compressor is the lifeblood of the shop. From powering impact wrenches and air ratchets to inflating tires and operating paint sprayers, its versatility is unmatched. But like any critical piece of equipment, air compressors require regular service and repair to maintain peak performance and avoid costly downtime. Finding reliable "air compressor service and repair near me" is therefore a crucial task.

Understanding the Need for Service

Ignoring routine maintenance is a surefire way to shorten the lifespan of your compressor. Several key areas demand attention:

- Oil Changes: For oil-lubricated compressors, regular oil changes are paramount. Dirty or degraded oil leads to increased friction, heat buildup, and ultimately, premature wear on the pump. Check your compressor's manual for the recommended oil type and change intervals.

- Air Filter Cleaning/Replacement: The air filter prevents dust and debris from entering the pump, which can score cylinder walls and damage valves. Regularly cleaning or replacing the filter ensures optimal airflow and compressor efficiency. A clogged filter forces the compressor to work harder, consuming more energy and reducing its output.

- Tank Draining: Condensation inevitably forms inside the air tank due to humidity in the compressed air. If left unchecked, this water can corrode the tank from the inside out, leading to leaks and even catastrophic failure. Most compressors have a drain valve at the bottom of the tank; drain it regularly, especially after heavy use. Some shops install automatic tank drains to automate this process.

- Belt Inspection: For belt-driven compressors, the belt's condition is critical. Check for cracks, fraying, or excessive wear. A worn belt can slip, reducing compressor output, or even break, halting operation completely. Proper belt tension is also essential; too loose, and it slips; too tight, and it stresses the bearings.

- Leak Detection: Air leaks waste energy and reduce compressor efficiency. Check all fittings, hoses, and connections for leaks using a soapy water solution. Bubbles will form at the site of a leak. Address any leaks promptly to minimize energy waste and maintain optimal pressure.

Common Compressor Repairs

Even with diligent maintenance, air compressors can experience failures. Some common issues include:

- Pump Failure: Often caused by lack of lubrication or contaminated air, pump failure can manifest as reduced output, excessive noise, or complete seizure. Rebuilding or replacing the pump is often necessary. Pump rebuild kits are available for many models and can be a cost-effective alternative to complete replacement.

- Motor Issues: The electric motor that drives the compressor can also fail due to overheating, voltage fluctuations, or simply age. Troubleshooting motor problems often requires a multimeter and a good understanding of electrical circuits. Replacing the motor is typically the solution.

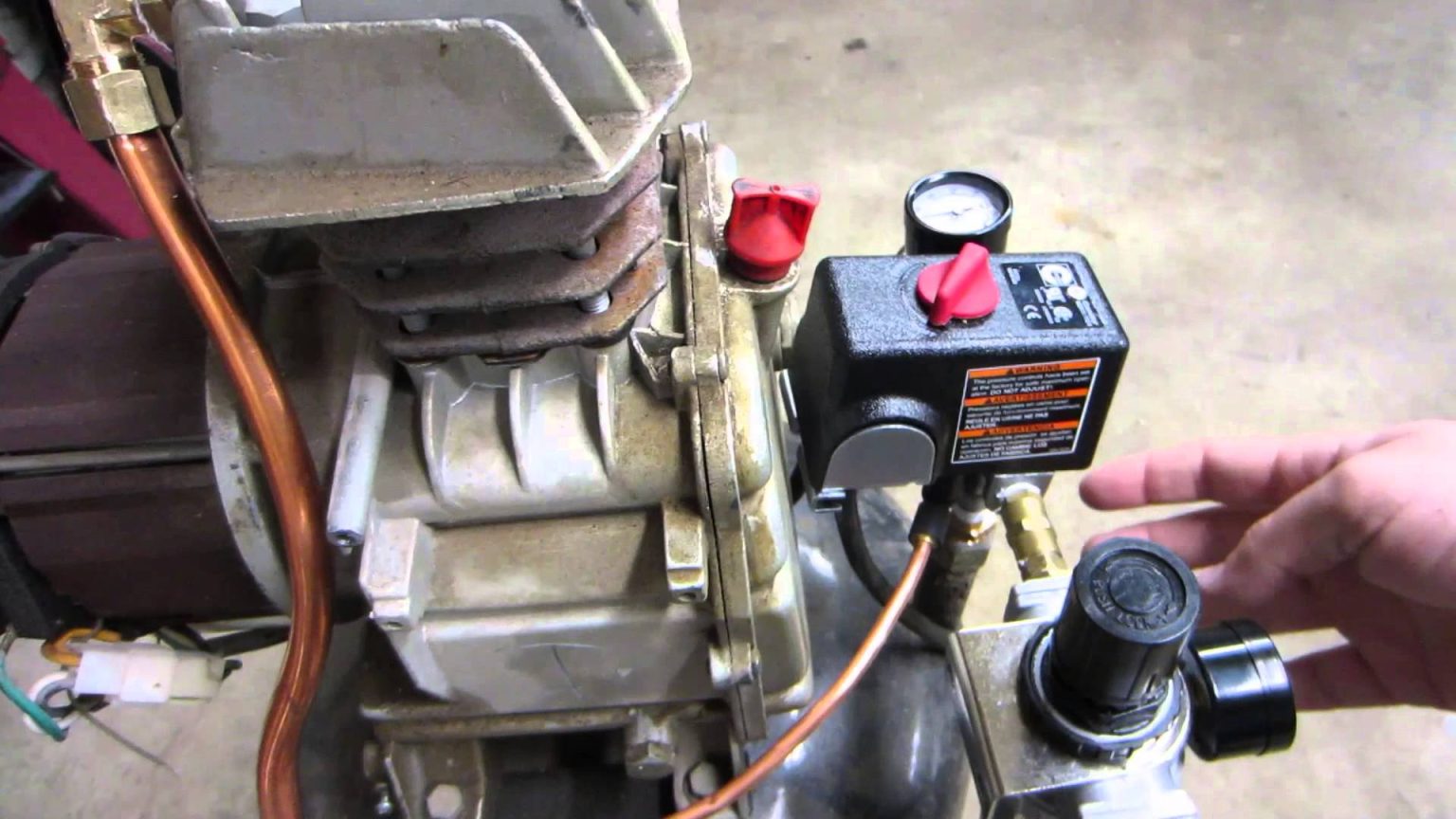

- Pressure Switch Problems: The pressure switch controls the motor, turning it on and off to maintain the desired tank pressure. A faulty pressure switch can cause the compressor to run continuously or not at all. Replacement is usually a straightforward repair.

- Check Valve Failure: The check valve prevents air from flowing back into the pump from the tank. A malfunctioning check valve can lead to backpressure and reduced compressor efficiency.

- Safety Valve Issues: The safety valve is a crucial safety device that prevents over-pressurization of the tank. If the safety valve is constantly releasing air, it indicates a problem with the pressure switch or another component. Never disable or bypass the safety valve.

Finding the Right Repair Service

When tackling repairs beyond your skill level, finding a reputable "air compressor service and repair near me" is essential. Consider these factors when choosing a service provider:

- Experience and Expertise: Look for a service provider with extensive experience in repairing a wide range of air compressor brands and models. Ask about their technicians' qualifications and training.

- Reputation: Check online reviews and ask for references from other shops or individuals. A reputable service provider will have a track record of providing quality repairs and excellent customer service.

- Parts Availability: A service provider with access to a wide range of replacement parts can expedite the repair process and minimize downtime.

- Warranty: Inquire about the warranty offered on repairs. A reputable service provider will stand behind their work and offer a warranty on both parts and labor.

- Cost: Obtain estimates from multiple service providers before making a decision. Be sure to compare the scope of work included in each estimate.

Regular maintenance and timely repairs are crucial for maximizing the lifespan and performance of your air compressor. By understanding the common service requirements and repair issues, and by choosing a reputable service provider when needed, you can keep your compressor running smoothly for years to come, ensuring that you always have the compressed air you need to get the job done.