Cheap Serpentine Belt Replacement Near Me

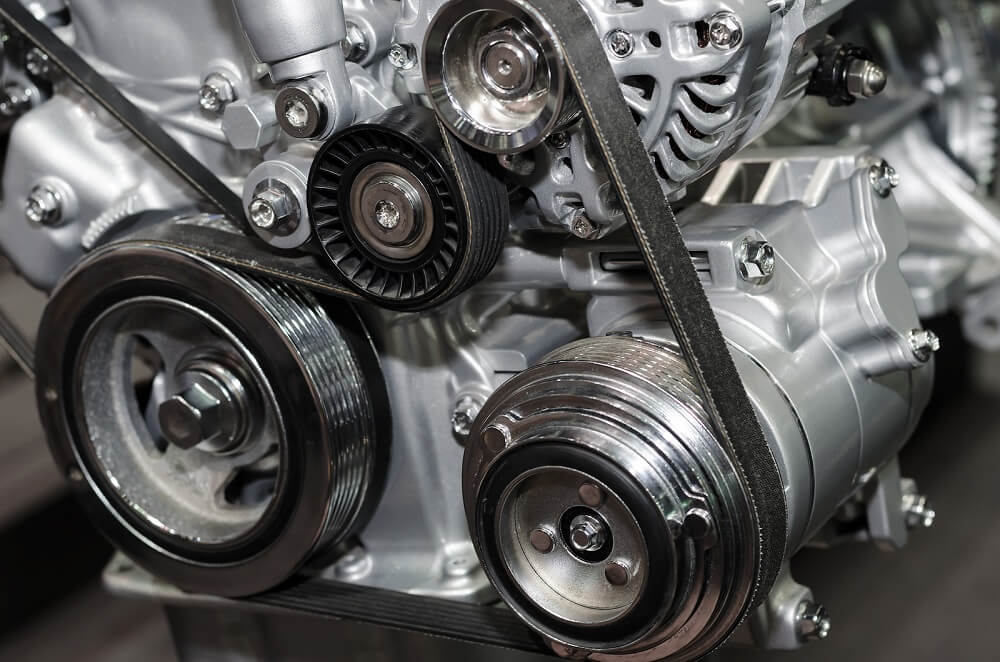

The ubiquitous serpentine belt, often the unsung hero of modern internal combustion engines, plays a crucial role in powering essential vehicle systems. From the alternator to the power steering pump, and the air conditioning compressor to the water pump in some configurations, the serpentine belt is the lifeline that keeps these components functioning. Finding a "cheap serpentine belt replacement near me" is a common search term, but understanding the intricacies involved beyond just price is paramount for automotive professionals.

Technical Specifications and Engineering Choices

Serpentine belts are typically constructed from EPDM (Ethylene Propylene Diene Monomer) rubber, reinforced with high-tensile cords. This composite material offers a balance of flexibility, strength, and resistance to heat and chemicals. The rib design is critical, affecting both grip and noise. Different vehicle manufacturers specify different rib profiles to optimize power transfer and minimize slippage under varying load conditions. The number of ribs and their depth are also critical parameters. A deeper rib profile generally provides better grip, while a higher number of ribs distributes the load more evenly, extending belt life.

Engineering choices also extend to the manufacturing process. Precision molding is essential to ensure consistent dimensions and prevent premature wear. Belt tension is another critical factor. Too little tension can lead to slippage, reducing the efficiency of driven components and potentially causing overheating (especially concerning the water pump). Too much tension, on the other hand, can place excessive stress on bearings and shorten the lifespan of both the belt and the driven components. Automotive manufacturers specify precise tension ranges, often requiring specialized tools for accurate measurement and adjustment.

Real-World Performance and Alternatives

While a "cheap" serpentine belt might seem appealing, it's crucial to consider its real-world performance. Lower-priced belts often utilize inferior materials and manufacturing processes, resulting in reduced lifespan, increased noise, and a higher risk of failure. This can lead to unexpected breakdowns and costly repairs. The alternative is investing in OEM (Original Equipment Manufacturer) or high-quality aftermarket belts from reputable brands. These belts are designed to meet or exceed the original specifications, ensuring optimal performance and longevity. These belts generally use higher quality EPDM and more precise rib profiles.

Alternatives to EPDM belts include those made with different compounds designed for extreme conditions. For example, some heavy-duty applications use belts with a higher temperature resistance or improved resistance to oil and other contaminants. However, these specialized belts often come at a higher price point and may not be necessary for standard passenger vehicles.

Pros and Cons: Cheap vs. Premium Serpentine Belts

Cheap Serpentine Belts:

Pros: Lower initial cost.

Cons: Reduced lifespan, increased risk of failure, potential for slippage and noise, may not meet OEM specifications, potentially damages pulleys due to improper fit or inferior material, more frequent replacements.

Premium Serpentine Belts:

Pros: Longer lifespan, reduced risk of failure, optimized performance, meets or exceeds OEM specifications, reduced noise, improved fuel efficiency due to less slippage, overall lower cost of ownership in the long run.

Cons: Higher initial cost.

Reliability Aspects and Maintenance Tips

The reliability of a serpentine belt is directly related to its quality and the maintenance it receives. Regular inspection is crucial. Look for signs of wear, such as cracks, fraying, glazing, or missing ribs. Listen for squealing noises, which can indicate slippage. Pay attention to the belt tension. Proper installation, using the correct tools and techniques, is also essential. Ensure that all pulleys are properly aligned and that the belt is routed correctly. Incorrect routing can lead to premature wear and failure.

Preventative maintenance includes inspecting pulleys for damage or wear. A worn or damaged pulley can significantly shorten the lifespan of the belt. Also, check for any leaks that could contaminate the belt, such as oil or coolant. Replacing the belt at the manufacturer's recommended interval, even if it doesn't show obvious signs of wear, is a wise investment.

Future Trends

The future of serpentine belt technology is likely to focus on improved materials and designs. Expect to see more belts made from advanced polymers that offer even greater durability and resistance to extreme temperatures and chemicals. Self-tensioning systems are becoming more common, reducing the need for manual adjustments. Furthermore, as electric vehicles become more prevalent, the demand for serpentine belts will decrease, but they will still be necessary in hybrid vehicles. The belts used in these vehicles will likely be engineered for increased efficiency, as the parasitic drag on the engine can significantly impact fuel economy.

The introduction of sensors for measuring belt tension and wear will allow for predictive maintenance, reducing the risk of unexpected failures. These sensors will communicate with the vehicle's computer, providing real-time data on the belt's condition and alerting the driver or service technician when replacement is necessary.

Forward-Looking Note

The automotive industry is in a state of constant evolution. While the immediate focus is on electrification, the internal combustion engine will remain a significant part of the vehicle fleet for years to come. Automotive professionals need to stay informed about the latest technologies and best practices to provide their customers with the best possible service. This includes understanding the nuances of seemingly simple components like the serpentine belt and making informed decisions about replacement parts. Prioritizing quality and reliability over initial cost will ultimately lead to greater customer satisfaction and a more sustainable automotive industry.