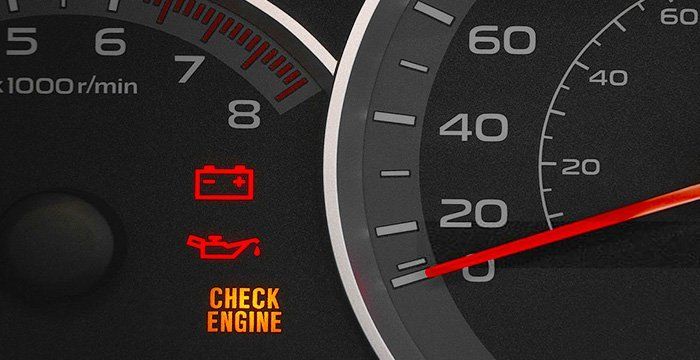

Check Engine Light Flashed Then Went Away

A flashing Check Engine Light (CEL), followed by its subsequent disappearance, is a common yet often perplexing issue for automotive professionals. It's tempting to dismiss it as a minor glitch, but ignoring such an event can lead to more significant problems down the line. Understanding the technical reasons behind this behavior, its implications for vehicle health, and proper diagnostic procedures is crucial for effective automotive service.

Understanding the Flashing CEL

A flashing CEL indicates a severe engine misfire. This is not simply a gentle cough; it signifies that unburnt fuel is being dumped into the exhaust system. The primary reason for the flashing light is to warn the driver of the potential damage to the catalytic converter. Unburnt fuel overheating the catalytic converter can cause it to melt or otherwise fail, a repair that can be costly.

The Engine Control Unit (ECU) monitors the crankshaft position sensor (CKP) and camshaft position sensor (CMP) signals to determine engine speed and cylinder position. When the ECU detects a misfire, it attempts to compensate by adjusting fuel trim and ignition timing. However, if the misfire persists, it triggers the flashing CEL. Once the misfire is no longer detected for a specific number of drive cycles (typically 3-4), the ECU may turn off the CEL, although the diagnostic trouble code (DTC) usually remains stored in memory.

Possible Causes and Diagnostic Procedures

Several factors can cause a misfire that triggers a flashing CEL, including:

- Ignition System Faults: Faulty spark plugs, ignition coils, or spark plug wires can prevent proper combustion. Modern vehicles often use coil-on-plug (COP) systems, which offer improved efficiency and reduced electrical interference compared to distributor-based systems. However, a failure in a single COP unit directly impacts a specific cylinder. Diagnostic procedures include visually inspecting spark plugs, using a multimeter to check coil resistance and primary/secondary voltages, and using an oscilloscope to analyze coil waveforms.

- Fuel System Problems: Issues with fuel injectors (clogged, leaking, or malfunctioning), fuel pump (low pressure), or fuel pressure regulator can lead to an incorrect air-fuel mixture. Fuel injector testing involves checking resistance, spray pattern, and flow rate. A fuel pressure gauge can verify fuel pump performance.

- Vacuum Leaks: Leaks in vacuum lines, intake manifold gaskets, or throttle body gaskets can disrupt the air-fuel mixture, causing a misfire. A smoke test is an effective method for identifying vacuum leaks. The use of propane or carburetor cleaner around suspected leak points can also reveal leaks as the engine RPM changes when the substance is sucked into the intake.

- Compression Issues: Worn piston rings, damaged valves, or a blown head gasket can reduce cylinder compression, hindering combustion. A compression test and a leak-down test are essential for diagnosing compression problems.

- Sensor Malfunctions: Faulty sensors, such as the mass airflow (MAF) sensor, oxygen (O2) sensors, or crankshaft position sensor (CKP), can provide inaccurate data to the ECU, leading to incorrect fuel and timing adjustments. Diagnosing sensor issues involves using a scan tool to monitor sensor readings and comparing them to specifications. A multimeter can also be used to check sensor voltages and resistances.

- EGR System Issues: A stuck-open or malfunctioning EGR valve can introduce too much exhaust gas into the intake manifold, leading to a lean mixture and misfire, particularly at idle.

Real-World Performance and Comparison with Alternatives

In a typical scenario, a customer might report a flashing CEL that occurred during acceleration, then disappeared after they reduced speed. This often points to an ignition system fault, such as a failing ignition coil that only misfires under load. Ignoring this issue can lead to a gradual deterioration of engine performance, reduced fuel economy, and eventually, permanent damage to the catalytic converter.

Compared to older carbureted systems, modern electronically fuel-injected systems offer significantly better fuel efficiency, lower emissions, and improved drivability. However, they are also more complex and require specialized diagnostic tools and knowledge. The increased complexity can make troubleshooting more challenging.

Reliability and Maintenance Tips

To maintain engine reliability and prevent misfires, regular maintenance is crucial:

- Spark Plug Replacement: Follow the manufacturer's recommended service interval for spark plug replacement. Use the correct spark plug type and gap specification.

- Fuel System Cleaning: Use fuel injector cleaner periodically to prevent clogging. Consider professional fuel system cleaning services for vehicles with high mileage or persistent fuel-related issues.

- Air Filter Replacement: Replace the air filter regularly to ensure proper airflow to the engine.

- Regular Inspection: Visually inspect vacuum lines, hoses, and wiring for damage or leaks.

Pros and Cons of Ignoring a Flashing CEL

Pros of Ignoring: Potentially avoids immediate repair costs (short-term).

Cons of Ignoring:

- Catalytic Converter Damage: This is the most significant risk. Replacing a catalytic converter is a costly repair.

- Reduced Fuel Economy: Misfires decrease engine efficiency, leading to higher fuel consumption.

- Engine Damage: Prolonged misfires can cause engine damage, such as cylinder wall scoring.

- Increased Emissions: Misfires increase harmful emissions.

- Further System Damage: The unburnt fuel can degrade oil, leading to other issues.

Future Trends

The automotive industry is moving towards more sophisticated engine management systems with increased sensor integration and more precise control over fuel and ignition. Future trends include:

- Advanced Combustion Strategies: Technologies like gasoline direct injection (GDI) and variable valve timing (VVT) are becoming more prevalent, optimizing combustion for improved efficiency and reduced emissions.

- Improved Diagnostics: Onboard diagnostics (OBD) systems are becoming more sophisticated, providing more detailed information about engine performance and potential problems. The increased use of cloud-based diagnostics will allow for remote monitoring and predictive maintenance.

- Electrification: As electric vehicles (EVs) become more common, internal combustion engine (ICE) related diagnostics will gradually decline, and the focus will shift to battery management systems and electric motor controls. Hybrid vehicles, however, will still require expertise in both ICE and electric systems.

Conclusion

A flashing CEL, even if it disappears, is a critical warning sign that should not be ignored. Proper diagnosis and repair are essential to prevent costly damage to the catalytic converter and other engine components. Automotive professionals must stay updated with the latest diagnostic techniques and technologies to effectively address these issues in modern vehicles. The increasing complexity of automotive systems demands continuous learning and adaptation to ensure quality service and customer satisfaction. The future of the automotive industry will be shaped by electrification and advanced engine management systems, requiring a forward-looking approach to training and expertise.