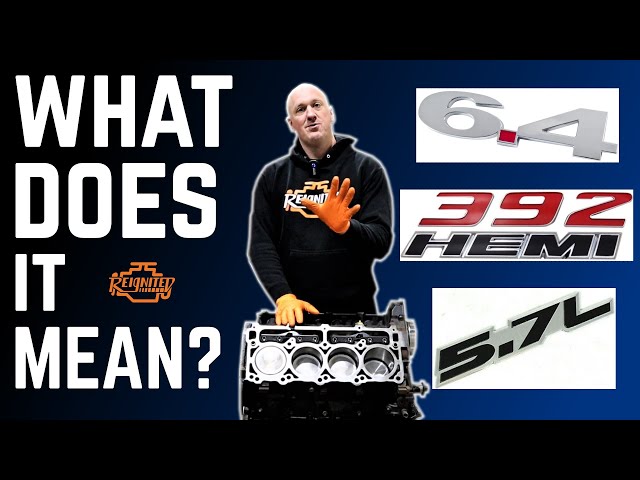

How Do You Know What Size Engine You Have

Determining an engine's size isn't just about bragging rights; it's crucial for diagnostics, repair, performance tuning, and even purchasing decisions. While the displacement, often expressed in liters (L) or cubic inches (CID), is the primary indicator, understanding how manufacturers arrive at that figure, along with the interplay of various engine parameters, offers valuable insights for automotive professionals.

Decoding the Displacement: A Technical Deep Dive

Engine displacement represents the total volume swept by all the pistons inside the cylinders during one complete engine cycle. The formula for calculating displacement is straightforward: Displacement = (π * (bore/2)2 * stroke) * number of cylinders. Bore refers to the diameter of the cylinder, while stroke is the distance the piston travels within the cylinder. Understanding this equation is fundamental. For example, a 5.0L V8 engine likely has a smaller bore and shorter stroke compared to a 6.2L V8, which impacts its power delivery characteristics.

Manufacturers often round the displacement figure for marketing purposes (e.g., a 4.6L engine might be badged as a 4.7L or even 5.0L). Accurate information is best obtained from the engine's identification plate, typically located on the engine block itself, the vehicle identification number (VIN) which can be decoded, or the vehicle's original documentation. Diagnostic tools connected to the ECU (Engine Control Unit) can also provide accurate engine displacement data.

Alternatives to Displacement: Power vs. Efficiency

While displacement strongly correlates with engine power, it's not the sole determinant. Turbocharging, supercharging, and other forced induction methods allow smaller displacement engines to generate power comparable to larger, naturally aspirated engines. For instance, a modern turbocharged 2.0L engine can produce similar horsepower and torque figures to a naturally aspirated 3.5L V6. This shift towards downsizing with forced induction is driven by increasing fuel economy and emissions regulations.

Comparison: Naturally Aspirated vs. Forced Induction

- Naturally Aspirated:

- Pros: Simpler design, generally lower maintenance costs, more linear throttle response.

- Cons: Lower power output for a given displacement, less fuel efficient at higher power demands.

- Forced Induction (Turbocharged/Supercharged):

- Pros: Higher power output for a given displacement, improved fuel economy in certain driving conditions (when not under boost).

- Cons: More complex design, potentially higher maintenance costs (turbocharger/supercharger failure), potential for turbo lag (turbocharged engines).

Real-World Performance and Engine Characteristics

The bore-to-stroke ratio significantly influences engine characteristics. A "square" engine has roughly equal bore and stroke. An "over-square" (short-stroke) engine has a larger bore than stroke, favoring higher RPM operation and potentially more peak horsepower but less low-end torque. Conversely, an "under-square" (long-stroke) engine has a smaller bore than stroke, producing more low-end torque but potentially limiting high-RPM performance.

Understanding these characteristics is crucial for diagnosing performance issues. For example, an engine that feels sluggish at low RPMs might be a symptom of an issue impacting torque production, possibly related to valve timing, fuel delivery, or ignition timing. Alternatively, an engine that struggles to rev freely at higher RPMs might indicate a problem with airflow, exhaust restriction, or limitations imposed by its bore-to-stroke ratio.

Reliability and Maintenance Considerations

Engine size can indirectly impact reliability. Larger displacement engines, particularly naturally aspirated ones, often operate at lower specific output (horsepower per liter), reducing stress on components and potentially increasing longevity. However, this is a generalization, and modern engine design and materials play a significant role.

Forced induction engines, while offering impressive power density, can be more sensitive to maintenance. Regular oil changes with high-quality synthetic oil are critical to prevent turbocharger/supercharger failure. Furthermore, proper cool-down procedures after strenuous driving are essential to prolong turbocharger life. Ignoring these maintenance requirements can lead to premature failure and costly repairs.

Specific maintenance tasks tied to engine size often relate to fluid capacities (oil, coolant), spark plug specifications (heat range), and potentially larger components like radiators. Consult the vehicle's repair manual for precise specifications and recommended maintenance intervals.

Future Trends: Hybridization, Electrification, and the IC Engine

The automotive industry is undergoing a rapid transformation. Hybridization and full electrification are becoming increasingly prevalent. However, the internal combustion engine (ICE) is unlikely to disappear entirely in the near future. Expect to see further advancements in ICE technology, including more efficient combustion strategies (e.g., homogeneous charge compression ignition - HCCI), variable compression ratios, and further refinements in forced induction systems.

Downsizing will continue to be a dominant trend, with manufacturers focusing on maximizing power density while minimizing fuel consumption and emissions. The integration of electric motors within hybrid powertrains will allow smaller displacement engines to operate more efficiently, providing supplemental power during acceleration and regenerative braking. Understanding the interplay between the ICE and electric motor in these hybrid systems will be crucial for future automotive technicians.

The ability to accurately identify and diagnose engine issues, regardless of engine size or technology, remains a fundamental skill for automotive professionals. Staying informed about the latest engine technologies and diagnostic techniques is essential for navigating the evolving automotive landscape.