How Long Does A Transmission Rebuild Take

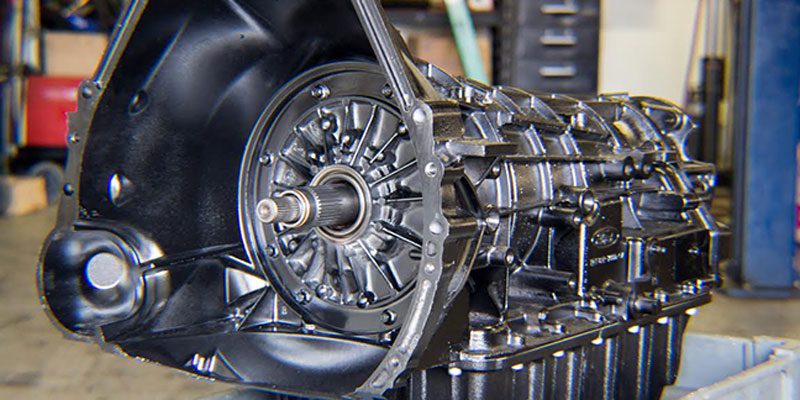

So, you're thinking about tackling a transmission rebuild, or maybe you've already dropped it off at the shop and are wondering why it's taking so long. The honest answer to "how long does a transmission rebuild take?" is: it depends. A lot of factors come into play, from the type of transmission to your experience level and the availability of parts. But let's break it down in detail so you can get a realistic expectation.

Factors Influencing Rebuild Time

Several key variables affect the timeframe for a transmission rebuild. Understanding these will help you estimate the project's duration and potentially identify bottlenecks.

1. Transmission Type

This is a big one. A simple 3-speed automatic like a GM TH350 or a Ford C4 will generally be much faster to rebuild than a complex modern 8-speed automatic, a continuously variable transmission (CVT), or a dual-clutch transmission (DCT). Manual transmissions are often simpler than automatics, but some performance-oriented manuals with intricate synchro designs can still be time-consuming.

Consider the number of internal components. More gears, clutches, valves, and sensors mean more parts to inspect, clean, and potentially replace. A TH350 might have around 100-150 parts inside, while a modern 8-speed could easily have over 300. The sheer number of components alone adds considerable time.

CVTs are a different beast entirely. While they lack traditional gears, their belt-and-pulley systems require specialized tools and knowledge. DCTs, with their two separate clutches and gearsets, essentially require rebuilding two transmissions in one housing.

2. Experience Level

This is self-explanatory. If you're a seasoned mechanic who's rebuilt dozens of transmissions, you'll be much faster than someone tackling their first rebuild. Experience translates to efficiency. You'll know where to look for common problems, have a better understanding of tolerances, and be more comfortable using specialized tools.

A professional transmission shop likely has dedicated technicians specializing in specific transmission types. They've seen the same issues repeatedly and know how to diagnose and repair them quickly. A DIYer will be learning as they go, which inevitably adds time. Don't underestimate the value of experience – it's not just about speed; it's also about avoiding costly mistakes.

3. Parts Availability

Nothing brings a project to a screeching halt like waiting for parts. If you need a rare or discontinued component, you might be searching for weeks or even months. Even common parts can be backordered due to supply chain issues. Before you even begin disassembling the transmission, research the availability of critical parts like friction clutches, steel plates, seals, filters, and valve body components.

Consider buying a master rebuild kit. These kits typically include all the essential wearable components. However, even with a rebuild kit, you might need to order additional hard parts like planetary gearsets, shafts, or valve body components if they're damaged. Factor in shipping time, especially if you're ordering from overseas.

4. Condition of the Transmission

A transmission that's suffered catastrophic failure will take longer to rebuild than one that's simply showing signs of wear and tear. If you've got broken gears, a cracked case, or a severely damaged valve body, the rebuild will be more complex and time-consuming. Extensive damage may even necessitate replacing the entire transmission.

Thoroughly inspect all components during disassembly. Look for cracks, wear, scoring, and any other signs of damage. The more damage you find, the longer the rebuild will take. Document everything with photos and notes – this will be invaluable when reassembling the transmission.

5. Tools and Equipment

Having the right tools makes a huge difference. You'll need a dedicated workspace, a transmission jack, a parts washer, a dial indicator, a torque wrench, and a selection of specialized tools specific to your transmission type. Trying to rebuild a transmission with inadequate tools is like trying to build a house with a butter knife – it's going to be frustrating and take a long time.

Investing in good-quality tools will save you time and prevent damage to the transmission. Consider renting or borrowing specialized tools if you don't want to purchase them outright. Some common specialized tools include clutch spring compressors, seal installers, and valve body testers.

Time Estimates

With all that said, let's get down to some rough estimates. Keep in mind that these are just averages and can vary significantly.

- Simple Automatic (TH350, C4): A DIYer with some experience might take 15-25 hours. A professional shop could complete it in 8-12 hours.

- Modern Automatic (4-6 speed): DIY: 25-40 hours. Professional: 12-20 hours.

- Complex Automatic (8+ speed, CVT, DCT): DIY: 40+ hours (potentially much more, and strongly discouraged for beginners). Professional: 20-40+ hours.

- Manual Transmission: DIY: 10-20 hours. Professional: 6-10 hours.

These estimates *do not* include the time required to remove and reinstall the transmission in the vehicle. Factor in an additional 4-8 hours for that process, depending on the vehicle and your experience.

The Rebuild Process: A Time Breakdown

Let's look at the typical steps involved in a transmission rebuild and how much time each step might take.

- Removal: 2-4 hours (depending on the vehicle and complexity).

- Disassembly and Inspection: 4-8 hours. This is where you'll identify damaged components and determine what needs to be replaced.

Thorough cleaning of all parts during this step is crucial!

- Parts Ordering: This is variable. It could take a few days to several weeks, depending on availability.

- Cleaning and Preparation: 2-4 hours. Cleanliness is paramount! Ensure all parts are free of debris before reassembly.

- Reassembly: 6-12+ hours. This is the most time-consuming part. Carefully follow the service manual and pay close attention to torque specifications.

- Installation: 2-4 hours.

- Testing and Adjustment: 1-2 hours. Check fluid levels and perform a test drive to ensure everything is working correctly.

Tips for Speeding Up the Process

While you can't magically make a rebuild go faster, here are a few tips to improve your efficiency:

- Organization: Keep all parts organized and labeled. Use plastic bags or containers to store components from each subassembly. Take photos during disassembly to help with reassembly.

- Service Manual: Obtain a detailed service manual specific to your transmission. This is your bible.

- Cleanliness: A clean workspace and clean parts will make the rebuild go much smoother.

- Patience: Don't rush. Take your time and double-check your work. Rushing will only lead to mistakes and delays.

- Ask for Help: If you're stuck, don't be afraid to ask for help from experienced mechanics or online forums.

Ultimately, rebuilding a transmission is a challenging but rewarding project. By understanding the factors that influence rebuild time and following the tips above, you can increase your chances of success and get your vehicle back on the road sooner.