How Much Does It Cost To Fix A Blown Fuse

Diagnosing and replacing a blown fuse is often perceived as a simple task, yet the seemingly minimal cost can quickly escalate if the underlying problem causing the fuse to blow isn't addressed. For automotive professionals, understanding the intricacies involved is crucial for accurate diagnosis, efficient repairs, and ultimately, customer satisfaction.

The Initial Assessment: More Than Just a Fuse

The immediate cost associated with replacing a blown fuse is negligible – typically a few cents to a dollar, depending on the amperage and type of fuse (e.g., blade, cartridge, maxi). However, the true cost lies in the diagnostic labor required to determine why the fuse blew in the first place. A blown fuse is a symptom, not the disease.

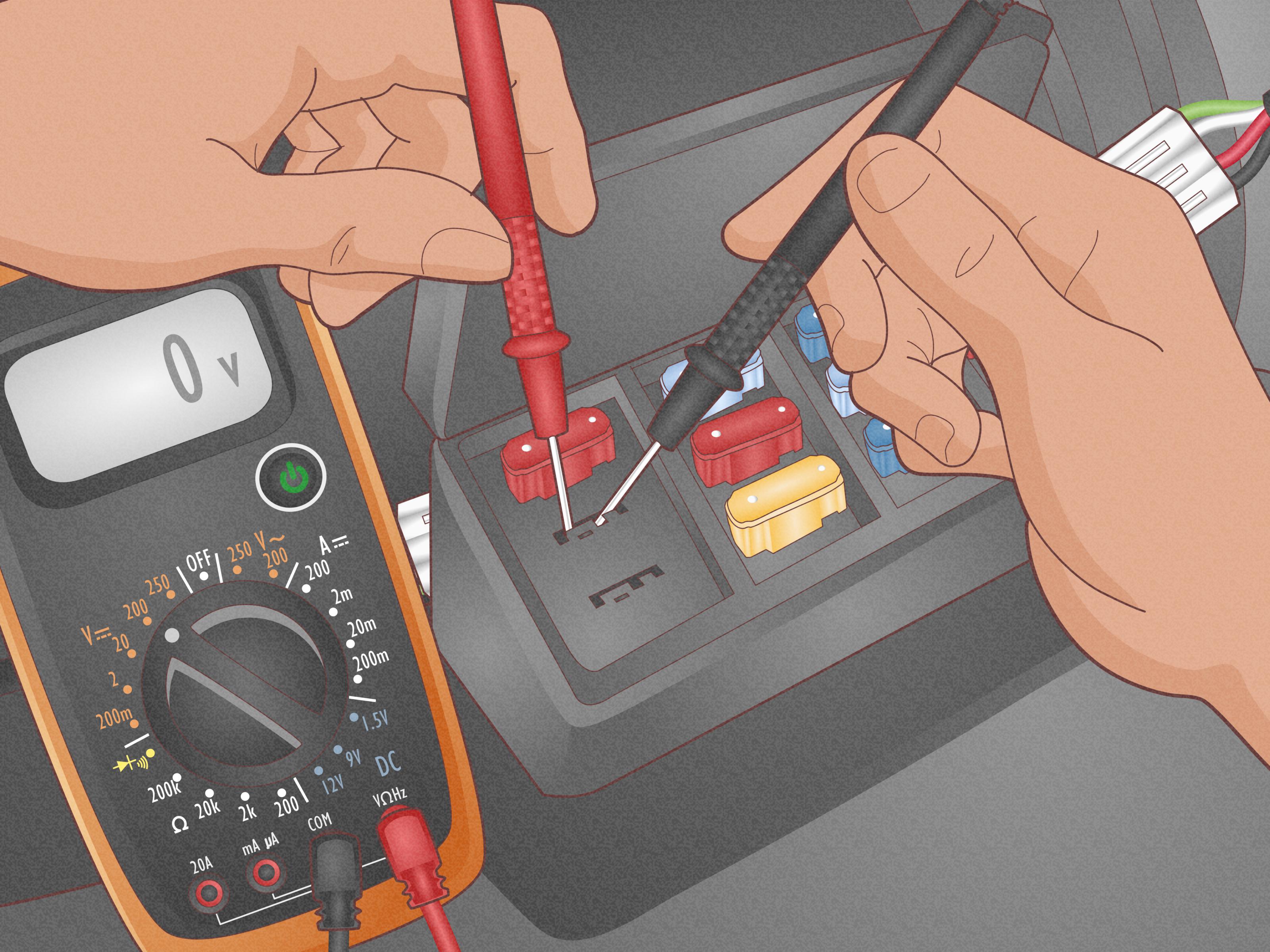

A simple multimeter test can confirm a blown fuse's continuity. However, a seasoned technician understands that a one-time replacement without further investigation is rarely the correct approach. The cost of labor for diagnosis can range from a half-hour to several hours, depending on the complexity of the circuit and the availability of accurate wiring diagrams.

Technical Specifications and Engineering Choices: The Fuse's Role

Fuses are designed as a safety device to protect electrical circuits from overcurrent. Their breaking capacity, measured in amps, indicates the maximum current the fuse can interrupt without failing catastrophically. Automotive fuses are typically rated to interrupt thousands of amps, preventing fires and protecting sensitive electronic components. The selection of fuse amperage is a critical engineering decision, balancing component protection with avoiding nuisance tripping due to normal inrush currents.

Different types of fuses exist, each with its own characteristics. Fast-blow fuses are designed to interrupt current quickly, suitable for circuits with sensitive electronic components. Slow-blow (time-delay) fuses can withstand short-duration overloads, common in circuits with motors or inductive loads. Using the incorrect type of fuse can lead to premature failures or, more dangerously, inadequate protection.

Real-World Performance and Troubleshooting

Common causes of blown fuses include:

- Short circuits: Damaged wiring, frayed insulation, or a component failure can create a direct path to ground, causing a massive current surge.

- Overloads: Connecting too many devices to a single circuit, or a malfunctioning component drawing excessive current.

- Water intrusion: Corrosion and short circuits can result from moisture in electrical connectors and wiring harnesses.

- Component failure: A faulty motor, solenoid, or other electrical component can draw excessive current.

Troubleshooting involves systematically isolating the affected circuit and using a multimeter to check for shorts to ground and excessive current draw. A visual inspection of wiring and connectors is also crucial. In some cases, a thermal imaging camera can help identify overheating components or wiring.

Alternatives and Their Pros and Cons

While fuses are the most common overcurrent protection device in automobiles, other technologies exist:

- Circuit breakers: These devices can be reset after an overload, eliminating the need for fuse replacement. Pros: Reusable, convenient. Cons: More expensive, can be reset repeatedly allowing damage to components, potentially slower response time than fuses.

- Solid-state circuit protection: Electronic devices that can detect and interrupt overcurrents. Pros: Very fast response time, can be programmed for specific current limits. Cons: More expensive, requires complex control circuitry.

- PTC (Positive Temperature Coefficient) Resistors: These devices increase their resistance significantly when overheated due to excessive current, limiting current flow. Pros: Self-resetting, relatively inexpensive. Cons: Slower response time than fuses, not suitable for high-current applications.

Fuses remain the dominant choice due to their simplicity, reliability, and low cost. However, solid-state solutions are becoming increasingly common in advanced electronic control units (ECUs) for enhanced protection and diagnostic capabilities.

Reliability Aspects and Maintenance Tips

Fuses themselves are generally reliable, but their effectiveness depends on proper installation and maintenance. Ensure that the correct amperage and type of fuse are used. Inspect fuse boxes and connectors for corrosion and damage. Regularly check the operation of electrical components to identify potential problems before they cause a fuse to blow. Using dielectric grease on connectors can help prevent corrosion.

Future Trends

The automotive industry is moving towards more complex electrical architectures with increased electrification and autonomous driving features. This will lead to:

- Smarter fuse boxes: Integrated diagnostics and remote monitoring of fuse status.

- Increased use of solid-state circuit protection: Faster response times and programmable current limits for sensitive electronic components.

- Zonal architectures: Centralized power distribution and control, reducing the number of individual fuses and simplifying wiring harnesses.

Forward-Looking Note

While the basic function of a fuse – protecting electrical circuits – will remain essential, the way fuses are implemented and managed will evolve significantly in the future. Automotive professionals need to stay updated on these trends to effectively diagnose and repair increasingly complex electrical systems. Investing in diagnostic tools and training related to advanced electrical architectures will be crucial for success in the evolving automotive landscape. A seemingly simple blown fuse repair today may require a completely different skillset tomorrow.