How To Clean Gas Tank Without Removing It

Okay, so you're looking to clean your gas tank without dropping it. A worthwhile endeavor! It can save you a ton of time and backache. It's definitely doable, but you need to be meticulous and understand the risks involved. This process is best for tanks with moderate sediment or rust; if you're dealing with severe internal decay, removal and professional cleaning/repair is non-negotiable.

Assessing the Situation

Before diving in, thoroughly assess the situation. What kind of contaminants are you dealing with? Is it just old, stale fuel that's gummed up? Or are you battling rust and sediment? The answer dictates your cleaning strategy.

Visual inspection is key. If possible, shine a bright light into the tank. You might be able to get a decent view through the filler neck. A borescope, if you have access to one, is ideal. Note the extent of rust, the type of sediment, and any obvious debris.

Consider the age of the vehicle and the type of fuel it's been using. Ethanol-blended fuels can exacerbate rust problems, especially in older tanks that weren't designed for them. If you suspect significant rust, be prepared for the possibility that cleaning might reveal pinholes or weakened areas, requiring you to rethink your approach.

Safety First

Working with gasoline is inherently dangerous. Take all necessary precautions.

- Disconnect the battery. This eliminates any chance of sparks during the process. Negative cable first!

- Work in a well-ventilated area. Outdoors is best. Gasoline fumes are flammable and can cause dizziness or worse.

- Wear appropriate personal protective equipment (PPE). This includes safety glasses or a face shield, chemical-resistant gloves, and clothing that covers your skin.

- Have a Class B fire extinguisher readily available.

- No smoking, open flames, or sources of ignition nearby.

The Cleaning Process: Step-by-Step

Here's a breakdown of the process, designed to be as effective as possible without removing the tank:

- Drain the Tank Completely. This is crucial. Use a siphon pump or drain plug (if equipped) to remove all the old fuel. Dispose of the fuel properly at a hazardous waste facility or recycling center. Don't just dump it!

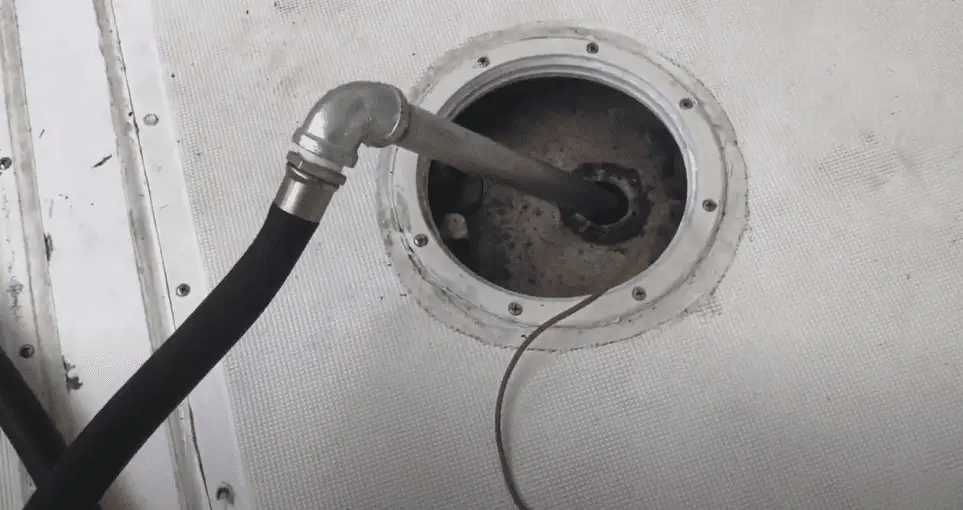

- Remove the Fuel Pump (If Accessible). Many modern vehicles have an in-tank fuel pump. Carefully disconnect the electrical connections and fuel lines, noting their orientation for reassembly. Place the pump in a sealed container to prevent fumes from escaping. Removing the pump gives you a larger opening to work with.

- Flush with a Solvent. Use a solvent designed for cleaning fuel tanks. Options include:

- Gasoline: While counterintuitive, fresh gasoline can help dissolve gum and varnish.

- Acetone: A strong solvent that can dissolve stubborn deposits. Be extra cautious with ventilation and PPE.

- Commercial Fuel Tank Cleaner: There are many specialized fuel tank cleaners available from auto parts stores. Follow the manufacturer's instructions carefully.

Pour a gallon or two of your chosen solvent into the tank. Seal the filler neck and any other openings with rags or duct tape. Then, vigorously shake the tank for several minutes to agitate the solvent and loosen the debris. Pay attention to the weight of the tank; it will likely be heavy with liquid, so get help if needed.

- Drain and Repeat. Drain the solvent into a suitable container for proper disposal. Inspect the drained solvent. If it's heavily contaminated, repeat the flushing process with fresh solvent until the drained liquid appears relatively clean.

- Pressure Washing (Optional, Requires Caution). If you have access to a pressure washer and a nozzle that can fit inside the filler neck, you can use it to blast away remaining debris. Use extreme caution! The pressure can damage the tank if not used carefully. Keep the nozzle moving and avoid focusing the spray on any one area for too long. Wear full PPE, including a face shield. This step is best performed outdoors and requires careful drying afterwards to prevent flash rust.

- Chemical Treatment for Rust (If Needed). If you're dealing with significant rust, consider using a chemical rust converter or etching solution. Products containing phosphoric acid are often effective. Pour the solution into the tank, slosh it around to coat all surfaces, and let it sit for the recommended time according to the product instructions. This will convert the rust into a more stable compound and help prevent further corrosion.

- Neutralize and Rinse. After using a rust converter, you'll typically need to neutralize the acid with a baking soda solution. Mix a generous amount of baking soda with water and pour it into the tank. Slosh it around, drain it, and then rinse the tank thoroughly with clean water until all traces of the neutralizing solution are gone.

- Drying is Critical. This is arguably the most important step to prevent flash rust. Use a shop vacuum to suck out as much water as possible. You can also use compressed air to blow out any remaining moisture. A hair dryer or heat gun (used cautiously and at a safe distance) can help speed up the drying process. The goal is to get the inside of the tank completely dry as quickly as possible. Some people recommend using a fuel stabilizer during this step to coat the inside of the tank and prevent rust formation.

- Inspect Again. Once the tank is dry, inspect it again to assess the effectiveness of the cleaning process. If you're not satisfied, you may need to repeat some of the steps or consider professional cleaning.

- Reinstall the Fuel Pump (If Removed). Carefully reinstall the fuel pump, ensuring all connections are secure and the fuel lines are properly attached. Use new O-rings or gaskets if necessary.

- Add Fresh Fuel and a Fuel Stabilizer. Add a few gallons of fresh fuel to the tank, along with a fuel stabilizer to prevent future gum and varnish buildup.

Important Considerations

- Fuel Filter: After cleaning the tank, replace the fuel filter. It's almost guaranteed to be clogged with debris.

- Fuel Lines: Consider flushing the fuel lines as well to remove any contaminants that may have been dislodged from the tank.

- Rust Prevention: After cleaning, consider using a fuel tank sealer to coat the inside of the tank and prevent future rust formation. However, be aware that some sealers can be incompatible with certain fuels (especially ethanol-blended fuels), so choose a product carefully.

- Professional Help: If you're uncomfortable with any of these steps, or if the tank is severely corroded, it's best to seek professional help. A qualified mechanic can properly clean and repair the tank, or replace it if necessary.

Disclaimer: This procedure is intended as a guide only. Always consult your vehicle's service manual for specific instructions and safety precautions. The author is not responsible for any damage or injury that may result from following these instructions.

Important Term: Flash Rust: This is a rapid formation of rust that occurs when bare metal is exposed to moisture and oxygen. It's a common problem when cleaning fuel tanks and can undo all your hard work if you don't dry the tank thoroughly.

Cleaning your gas tank without removing it is a challenging but achievable task. With patience, careful planning, and a commitment to safety, you can restore your fuel system to proper working order. Good luck!