How To Know If Wheel Bearing Is Going Out

Hey there, gearheads! A failing wheel bearing is one of those things that can go from a minor annoyance to a major safety hazard surprisingly quickly. Diagnosing it early can save you from a roadside breakdown, expensive repairs, and potentially dangerous situations. This guide is designed to give you the knowledge and techniques to identify a failing wheel bearing like a pro, long before it leaves you stranded.

Understanding Wheel Bearings

First things first: let's talk about what wheel bearings actually do. They're essentially the unsung heroes of your wheel assembly. They are rolling-element bearings, designed to allow your wheels to rotate smoothly with minimal friction. Think of them as tiny, precisely engineered ball or tapered roller assemblies sandwiched between two smooth metal races. The inner race is mounted on the hub or spindle, while the outer race is housed in the knuckle or hub carrier. The rolling elements, lubricated by grease, sit between these races, allowing the wheel to spin freely.

There are primarily two types of wheel bearings found in modern vehicles:

- Tapered Roller Bearings: Often found in older vehicles and trucks, these bearings are designed to handle both radial (side-to-side) and axial (thrust) loads. They require periodic adjustment to maintain proper preload.

- Sealed Ball Bearings (Hub Assemblies): Increasingly common, these are pre-greased and sealed units that are designed to be maintenance-free. They typically come as a complete hub assembly, making replacement relatively straightforward, but adjustment isn't possible.

When these bearings start to wear, the carefully controlled clearances increase, the grease degrades, and the rolling elements can become damaged. This leads to increased friction, noise, and eventually, catastrophic failure. Recognizing the early signs is key.

Symptoms of a Failing Wheel Bearing

Okay, let's get down to brass tacks. Here's what to listen and feel for:

1. Noise: The Tell-Tale Grind

The most common and often first symptom is noise. This isn't just any noise; it's a very specific type. It's typically described as:

- A rumbling or grinding sound: Imagine the sound of rocks tumbling in a washing machine, only subtler. This is usually more pronounced at higher speeds.

- A humming or whining noise: This can be subtle at first, almost like tire noise, but it will gradually increase in volume and pitch.

- Noise that changes with speed: This is a key indicator. A failing wheel bearing noise will generally get louder and potentially change in pitch as your speed increases. Deceleration can also influence the noise, with some bearings becoming quieter and others louder.

- Noise that changes with steering: This is another critical clue. Turning the steering wheel can load or unload the bearing, causing the noise to change or disappear altogether. Typically, if the noise gets louder when turning to the left, it suggests a problem with the right wheel bearing, and vice versa. This is because turning shifts the weight of the vehicle to the opposite side.

Important Note: Tire noise, brake noise, and even driveline noise can sometimes mimic a failing wheel bearing. Pay close attention to the characteristics described above to differentiate. Road surface can also be a factor, try to test the noise on a variety of road surfaces.

2. Play and Vibration: Feeling the Trouble

Excessive play in the wheel is another significant symptom. This requires a hands-on approach. Here's how to check it:

- Lift the vehicle: Securely jack up the vehicle and support it with jack stands. Never work under a vehicle supported only by a jack.

- Grab the wheel: Grip the wheel at the 12 o'clock and 6 o'clock positions.

- Rock the wheel: Attempt to rock the wheel back and forth. You're looking for any noticeable movement or clunking. A small amount of play is normal, but excessive play (more than a few millimeters) indicates a problem.

- Repeat at 3 o'clock and 9 o'clock: This will help isolate play in the tie rod ends as well.

- Spin the wheel: While the wheel is off the ground, spin it by hand. Feel for any roughness, binding, or unusual vibrations.

In addition to play, you might also feel vibrations through the steering wheel or floorboard, especially at higher speeds. This is a sign that the bearing is severely worn and causing imbalance.

3. ABS Issues: A Secondary Indicator

On vehicles equipped with Anti-lock Braking Systems (ABS), a failing wheel bearing can sometimes trigger ABS-related issues. This is because the ABS sensor relies on a consistent signal from the wheel speed sensor, which is often integrated into the hub assembly. Excessive play or damage to the bearing can disrupt this signal, leading to:

- ABS warning light: The ABS warning light may illuminate on the dashboard.

- Erratic ABS activation: The ABS system might activate unnecessarily, even under normal braking conditions.

However, an ABS light can be triggered by many things, so don't automatically assume it's the wheel bearing. A diagnostic scan with an OBD-II scanner can help pinpoint the exact cause.

4. Uneven Tire Wear: A Visual Clue

A failing wheel bearing can cause uneven tire wear, particularly on the inside or outside edge of the tire. This is because the excessive play in the bearing can allow the wheel to wobble slightly, causing the tire to scrub against the road surface. Examine your tires for unusual wear patterns. Note that alignment issues can also cause uneven tire wear, so consider this as part of the overall diagnostic picture.

5. Heat: Proceed with Caution

A failing wheel bearing generates excessive heat due to increased friction. After driving, carefully (and I mean carefully) touch the hub of each wheel. If one hub is noticeably hotter than the others, it could indicate a failing wheel bearing. Do not touch the hub immediately after braking as the brakes themselves generate a large amount of heat. Exercise extreme caution, as a severely overheating bearing can be hot enough to cause burns. Use an infrared thermometer to get a more accurate and safe reading.

Confirming Your Diagnosis

Once you've identified potential symptoms, it's time to confirm your diagnosis. Here are a few additional steps you can take:

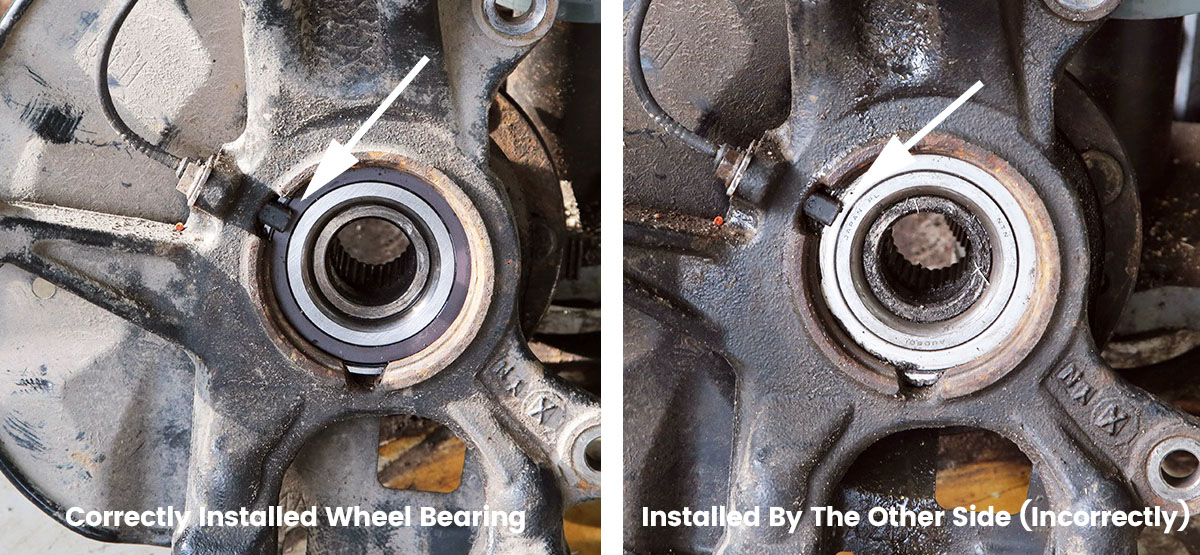

- Visual Inspection: With the wheel removed, visually inspect the hub assembly. Look for signs of grease leakage, damage to the seals, or corrosion.

- Bearing Preload Check (Tapered Roller Bearings Only): If your vehicle has tapered roller bearings, check the preload. This involves tightening the bearing nut to a specific torque and then backing it off slightly. Consult your vehicle's repair manual for the correct procedure and specifications.

- Stethoscope (Optional): A mechanic's stethoscope can be used to listen to the bearing while the wheel is spinning. Place the stethoscope probe on the knuckle near the bearing and listen for any unusual noises.

Next Steps

If you've confirmed that your wheel bearing is indeed failing, it's time to take action. Continuing to drive on a bad wheel bearing can lead to:

- Complete bearing failure: This can cause the wheel to seize up, potentially leading to a loss of control.

- Damage to other components: A failing bearing can damage the hub, spindle, or other parts of the suspension system.

Depending on your skill level and available tools, you can either replace the wheel bearing yourself or take your vehicle to a qualified mechanic. Replacing a wheel bearing can be a challenging task, especially on vehicles with press-fit bearings. Always consult your vehicle's repair manual for specific instructions and torque specifications. And remember, safety first! Use proper safety precautions when working on your vehicle.

By understanding the symptoms of a failing wheel bearing and following these diagnostic steps, you can catch the problem early and prevent potentially serious consequences. Happy wrenching!