How To Replace Fuel Level Sensor

The fuel level sensor, often called the fuel sending unit, is a crucial component in your vehicle's fuel system. It's responsible for accurately reporting the amount of fuel remaining in the tank to the fuel gauge on your dashboard. A malfunctioning fuel level sensor can lead to frustrating and potentially dangerous situations, such as running out of gas unexpectedly. This article provides a practical guide for car owners and mechanics on how to replace a fuel level sensor, focusing on maintenance, troubleshooting, and common real-world issues.

Understanding the Fuel Level Sensor

Before diving into the replacement process, it's essential to understand how the fuel level sensor works. Typically, it consists of a float, an arm, and a variable resistor. The float rises and falls with the fuel level, moving the arm, which in turn changes the resistance in the variable resistor. This resistance is then interpreted by the car's computer and displayed as the fuel level on the gauge.

Common Symptoms of a Failing Fuel Level Sensor

Recognizing the symptoms of a faulty fuel level sensor is the first step toward resolving the issue. Here are some common indicators:

- Inaccurate fuel gauge reading: The gauge may display incorrect fuel levels, fluctuating erratically, showing empty when the tank is full, or full when the tank is nearly empty.

- Fuel gauge stuck at a specific level: The gauge may remain fixed at empty or full, regardless of the actual fuel level.

- Check engine light: In some cases, a faulty fuel level sensor can trigger the check engine light. A diagnostic scan will reveal a code related to the fuel level sensor circuit.

- Poor fuel economy: Although less common, an inaccurate fuel level reading can indirectly affect fuel economy calculations if the car's computer relies on this data.

Troubleshooting a Suspected Fuel Level Sensor Problem

Before automatically assuming the fuel level sensor is bad, it's wise to perform some basic troubleshooting steps:

- Check the fuel gauge fuse: A blown fuse can prevent the fuel gauge from working correctly. Consult your owner's manual to locate the fuel gauge fuse and inspect it. Replace it if necessary.

- Inspect the wiring and connections: Examine the wiring harness and connectors leading to the fuel level sensor for any signs of damage, corrosion, or loose connections. Clean corroded connections and repair any damaged wiring.

- Use a multimeter to test the sensor: With the fuel tank partially empty, use a multimeter to measure the resistance across the sensor terminals. Compare the reading to the manufacturer's specifications. An open circuit or a reading outside the specified range indicates a faulty sensor. This step requires knowledge of your car's specific wiring diagram.

- Consult a diagnostic scan tool: If the check engine light is on, a diagnostic scan tool can reveal specific trouble codes related to the fuel level sensor circuit. Common codes include P0460 (Fuel Level Sensor Circuit Malfunction), P0461 (Fuel Level Sensor Circuit Range/Performance), and P0462 (Fuel Level Sensor Circuit Low Input).

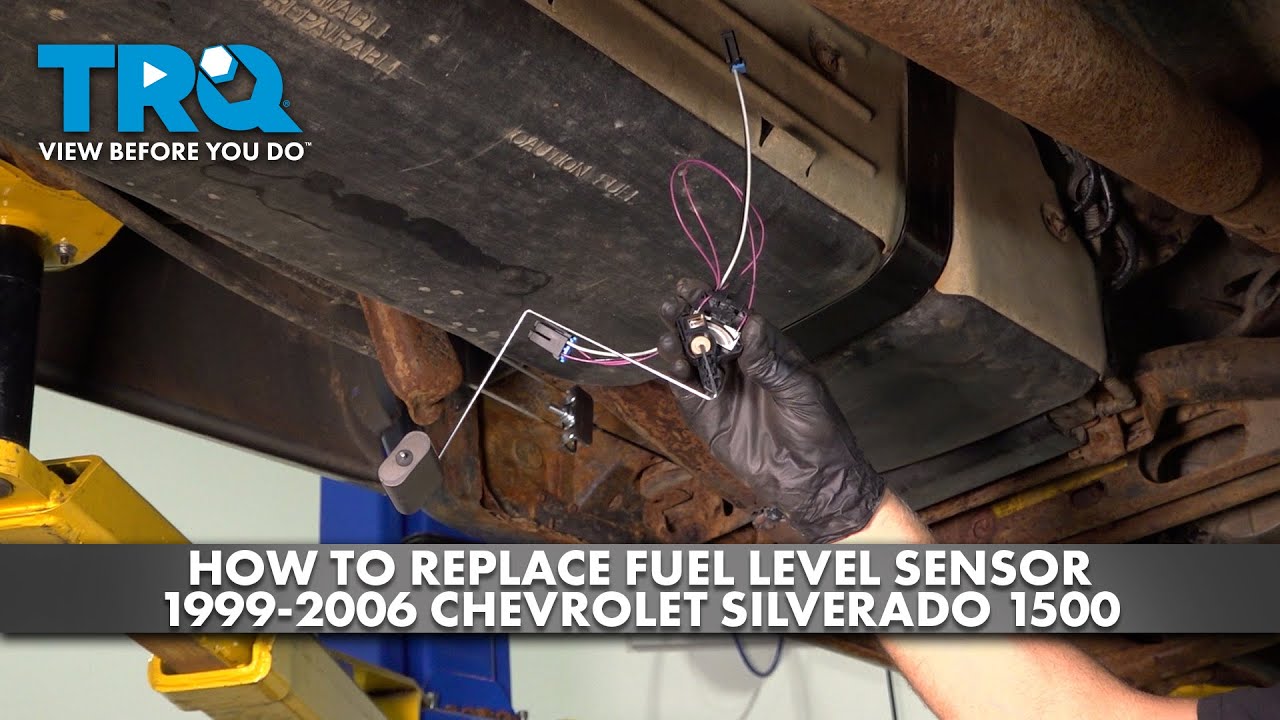

Replacing the Fuel Level Sensor: A Step-by-Step Guide

Replacing the fuel level sensor typically involves accessing the fuel tank, which can be located either inside the car (under the rear seat) or underneath the vehicle. Safety is paramount during this process. Always work in a well-ventilated area, disconnect the negative battery cable, and avoid any sources of ignition.

Tools and Materials Needed

- New fuel level sensor

- Socket set and wrenches

- Screwdrivers (Phillips and flathead)

- Fuel line disconnect tool (if necessary)

- Multimeter

- Safety glasses

- Gloves

- Drain pan

- Jack and jack stands (if accessing the tank from underneath)

- Wheel chocks

Step-by-Step Instructions

- Prepare the vehicle: Disconnect the negative battery cable. If accessing the fuel tank from underneath, safely raise the vehicle using a jack and support it with jack stands. Chock the rear wheels for added safety. If accessing from inside the car, remove the rear seat (usually held in place by clips or bolts).

- Locate the fuel tank access panel: The access panel is usually a metal or plastic cover held in place by screws or bolts. Remove the panel to expose the fuel pump/fuel level sensor assembly.

- Disconnect the fuel lines and electrical connectors: Carefully disconnect the fuel lines from the fuel pump assembly. Use a fuel line disconnect tool if required. Place a drain pan underneath to catch any spilled fuel. Disconnect the electrical connectors leading to the fuel pump and fuel level sensor.

- Remove the fuel pump/fuel level sensor assembly: This assembly is typically secured to the fuel tank with a retaining ring or screws. Use the appropriate tool to remove the retaining ring or screws. Carefully lift the assembly out of the tank, being mindful of the float arm.

- Separate the fuel level sensor from the fuel pump (if necessary): In some cases, the fuel level sensor is integrated with the fuel pump and can be replaced as a unit. In other cases, the sensor is a separate component that can be detached from the fuel pump.

- Install the new fuel level sensor: Install the new fuel level sensor, ensuring it is properly aligned and secured. If replacing the entire fuel pump/sensor assembly, ensure all connections are tight.

- Reinstall the fuel pump/fuel level sensor assembly: Carefully lower the assembly back into the fuel tank, ensuring the float arm moves freely. Secure it with the retaining ring or screws.

- Reconnect the fuel lines and electrical connectors: Reconnect the fuel lines and electrical connectors. Ensure they are securely attached.

- Reinstall the access panel: Replace the access panel and secure it with the screws or bolts.

- Reinstall the rear seat (if applicable): If the access panel was located under the rear seat, reinstall the seat.

- Lower the vehicle (if applicable): If the vehicle was raised, carefully lower it back to the ground.

- Reconnect the negative battery cable: Reconnect the negative battery cable.

- Test the fuel gauge: Turn the ignition key to the "on" position (without starting the engine) and observe the fuel gauge. It should now display the correct fuel level.

- Check for leaks: Start the engine and check for any fuel leaks around the fuel pump assembly and fuel lines.

Real-World Examples and Common Issues

Example 1: Honda Civic (2006-2011) Many Honda Civic owners experience issues with the fuel level sensor causing the fuel gauge to fluctuate wildly or get stuck at empty. The problem often stems from corrosion on the sensor's contacts due to ethanol in the fuel. Solution: Replacing the fuel level sensor and using fuel additives to help clean the fuel system can help prevent future corrosion. Some owners opt to replace the entire fuel pump assembly, as it often comes with a new, updated sensor design.

Example 2: Ford F-150 (2004-2008) Ford F-150 trucks from this era are known for fuel level sensor issues, particularly a sudden drop to empty after filling the tank. The cause is frequently attributed to a faulty sending unit. Solution: Replacing the fuel level sensor is the most common fix. In some cases, the fuel pump itself may be failing, requiring replacement of the entire assembly.

Example 3: Toyota Camry (2007-2011) Some Toyota Camry owners report inaccurate fuel readings, particularly after the car has been sitting for a while. This is often related to a build-up of deposits on the sensor's float or resistor. Solution: Using a fuel system cleaner regularly can help prevent deposit build-up. If the problem persists, replacing the fuel level sensor is necessary.

Common Issues & Solutions:

Problem: Difficulty removing the fuel lines. Solution: Use a specialized fuel line disconnect tool that fits your vehicle's fuel line connectors. Apply penetrating oil to the connectors to help loosen them. Problem: Retaining ring is difficult to remove. Solution: Use a dedicated fuel pump retaining ring tool. Apply penetrating oil to the ring threads. Be careful not to damage the tank or the retaining ring. Problem: New fuel level sensor is not reading correctly. Solution: Double-check all connections. Ensure the sensor is properly installed and calibrated (if required). Verify the sensor's resistance readings with a multimeter. Problem: Fuel smell after installation. Solution: Thoroughly inspect all fuel line connections for leaks. Tighten any loose connections. If the smell persists, check the fuel tank vent. Problem: Check engine light remains on after replacement. Solution: Use a diagnostic scan tool to clear the trouble codes. If the code returns, double-check the installation and wiring. Consult a mechanic for further diagnosis if needed.

Maintaining Your Car's Fuel System for Longevity

Preventative maintenance is key to keeping your car's fuel system in top condition and avoiding fuel level sensor issues. Here are some tips:

- Use high-quality fuel: Using high-quality fuel from reputable gas stations helps prevent the build-up of deposits in the fuel system.

- Use fuel system cleaners: Regularly use a fuel system cleaner to help remove deposits and keep the fuel injectors and fuel level sensor clean.

- Avoid running the fuel tank too low: Running the fuel tank consistently low can draw sediment and debris from the bottom of the tank into the fuel system, potentially damaging the fuel pump and fuel level sensor.

- Address any fuel system issues promptly: If you notice any symptoms of a fuel system problem, such as poor fuel economy or difficulty starting, address them promptly to prevent further damage.

- Regular inspections: During routine maintenance, have a mechanic inspect the fuel lines, fuel filter, and fuel tank for any signs of damage or leaks.

Replacing a fuel level sensor is a task that can be tackled by experienced DIYers and mechanics alike. By understanding the symptoms, troubleshooting steps, and replacement procedures, you can effectively address fuel level sensor issues and keep your car running smoothly for years to come.