Is The Emergency Brake A Hydraulic System

The world of automotive engineering is filled with systems that often operate behind the scenes, silently ensuring our safety and control. One such system, frequently misunderstood, is the emergency brake, also known as the parking brake or handbrake. While its name suggests a last-resort braking method, its primary function is to hold a vehicle securely in place when parked. But is this crucial system a hydraulic one, like the main braking system we rely on during driving? Let's dive into the mechanics and find out.

Hydraulic Brakes: A Quick Recap

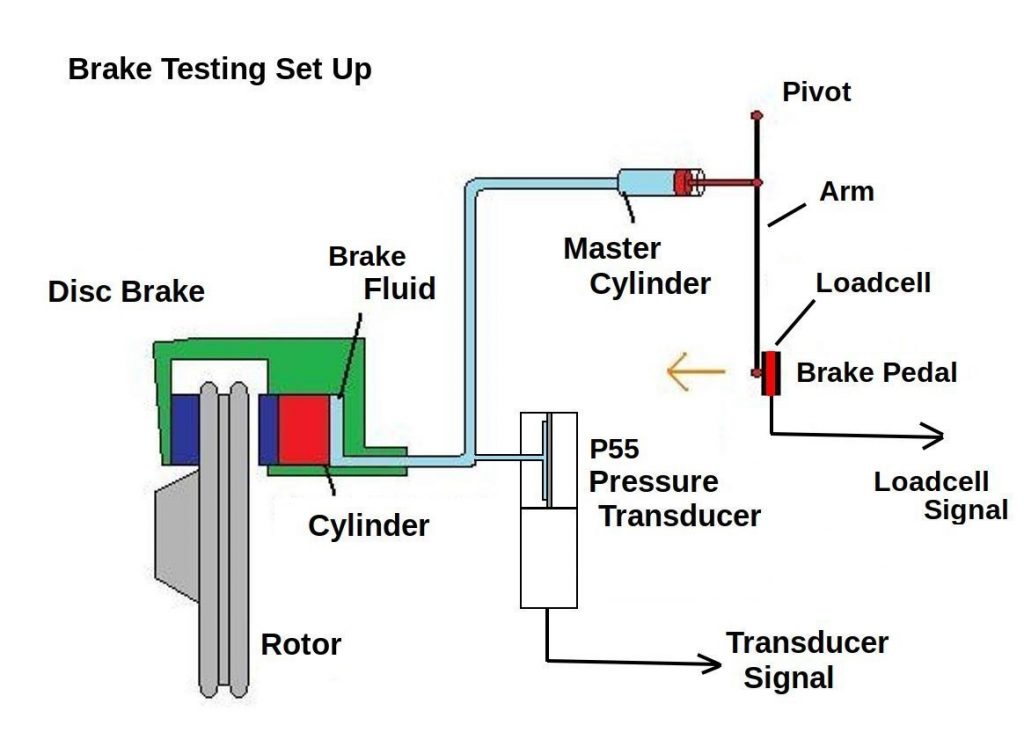

Before dissecting the emergency brake, it's essential to understand the operation of a typical hydraulic braking system. In a nutshell, it utilizes Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions throughout the fluid. This principle allows a small force applied at the brake pedal to be amplified into a much larger force at the brake calipers or drums, stopping the vehicle.

Here's a simplified breakdown:

- The driver presses the brake pedal, pushing a piston in the master cylinder.

- The master cylinder contains brake fluid, which is forced through brake lines.

- This pressurized fluid reaches the brake calipers (for disc brakes) or wheel cylinders (for drum brakes).

- In disc brakes, the pressure forces pistons in the calipers to clamp brake pads against a rotor. In drum brakes, the pressure forces pistons in the wheel cylinders to push brake shoes against a drum.

- The friction between the pads and rotor or shoes and drum slows down and stops the wheels.

Hydraulic systems offer significant advantages, including efficient force transmission and relatively simple design. However, they are susceptible to leaks and require careful maintenance to prevent brake failure.

The Emergency Brake: Cable-Actuated Simplicity

Now, let's address the central question: is the emergency brake hydraulic? The answer, in the vast majority of vehicles, is a resounding no. Emergency brakes are typically mechanical systems, relying on cables, levers, and linkages to apply braking force.

The typical emergency brake system works as follows:

- The driver engages the emergency brake using a lever, pedal, or electronic switch.

- This action pulls on a steel cable(s) connected to the rear brakes.

- The cable pulls on a lever mechanism at each rear wheel, applying the brakes independently of the hydraulic system.

- In vehicles with rear disc brakes, the emergency brake often uses a separate, smaller brake pad that presses against the inside of the rotor, or a dedicated drum brake system within the rotor's "hat".

- In vehicles with rear drum brakes, the emergency brake cable often actuates the same brake shoes used by the hydraulic system, but through a mechanical linkage.

The mechanical nature of the emergency brake provides several key benefits:

- Redundancy: It offers an independent braking system in case of hydraulic brake failure.

- Simplicity: The design is relatively simple and robust, making it less prone to failure compared to a complex hydraulic system.

- Holding Power: It provides a consistent holding force, essential for parking on inclines.

- Cost-effectiveness: Mechanical systems are generally less expensive to manufacture and maintain.

Think of it this way: imagine a bicycle brake. You squeeze the lever, which pulls a cable, which in turn activates the brake pads. The emergency brake operates on a similar principle, albeit with more sophisticated linkages and mechanisms.

Why Not Hydraulic? The Case Against Hydraulics in Emergency Brakes

While hydraulic systems offer advantages, there are several reasons why they aren't commonly used for emergency brakes:

- Dependency on Fluid Pressure: A hydraulic emergency brake would still rely on the brake fluid in the system. If the primary hydraulic system failed due to a leak, the emergency brake would likely be compromised as well. The point of the emergency brake is to be an entirely separate system.

- Complexity: Implementing a separate hydraulic circuit for the emergency brake would add significant complexity and cost to the vehicle's braking system.

- Temperature Sensitivity: Hydraulic fluids can be affected by temperature variations, potentially impacting the performance of a hydraulic emergency brake. Cables are less susceptible to such temperature-related issues.

- "Set and Forget" Functionality: The emergency brake is designed to be engaged and left engaged for extended periods. Hydraulic systems are more prone to leaks and pressure loss over time, which could lead to the vehicle rolling away. A mechanical system provides a more reliable and stable holding force.

Exceptions to the Rule: Electro-Hydraulic Parking Brakes

While the vast majority of vehicles use cable-actuated emergency brakes, there are exceptions. Some modern vehicles, particularly those with advanced electronic systems, employ electro-hydraulic parking brakes (EHPB). These systems still utilize hydraulic pressure, but the pressure is generated by an electric motor-driven pump rather than the driver's foot. However, even in these systems, the hydraulic actuation is often localized to the caliper. The electric motor and electronic control unit (ECU) replace the mechanical lever and cable, but the final force application is still often achieved through a dedicated mechanical actuator within the caliper itself, providing a robust failsafe.

In an EHPB system, the driver activates the parking brake using a switch. The ECU then commands the electric pump to generate hydraulic pressure, which applies the brake calipers. These systems offer several advantages, including:

- Integration with Electronic Stability Control (ESC): EHPB systems can be integrated with ESC to provide additional stability during emergency braking situations.

- Automatic Engagement: Some EHPB systems can automatically engage when the vehicle is parked on an incline or when the engine is turned off.

- Reduced Driver Effort: Engaging and disengaging the parking brake requires minimal effort.

- Aesthetic Integration: The lack of a traditional hand lever improves interior design flexibility.

However, even with EHPB systems, manufacturers often incorporate mechanical override mechanisms in case of electrical or hydraulic failure. This ensures that the vehicle can still be safely secured in an emergency situation.

Conclusion: A Mechanical Safeguard

In conclusion, the emergency brake, in its traditional and most common form, is not a hydraulic system. It's a cleverly engineered mechanical system that provides a crucial layer of redundancy and safety. While electro-hydraulic parking brakes are emerging, they often retain a degree of mechanical actuation for reliability. So, the next time you engage your emergency brake, remember that you're relying on a robust and dependable mechanical system designed to keep your vehicle securely in place.

Knowing the basics of how your car works is not just interesting – it empowers you to maintain it better and respond more effectively in emergencies. The emergency brake, a simple yet vital component, is a prime example of this.