Nissan 240sx Basic Suspension

The Nissan 240SX, particularly the S13 and S14 generations, enjoys legendary status among car enthusiasts, drifters, and tuners. One of the key reasons for its popularity is its well-designed, responsive suspension system. Understanding the fundamentals of the 240SX suspension is crucial for anyone looking to improve its handling, maintain it properly, or even just appreciate its engineering. This article will provide a detailed technical breakdown of the 240SX suspension, common issues, and best practices for maintenance and modification.

Background: The 240SX Suspension Design

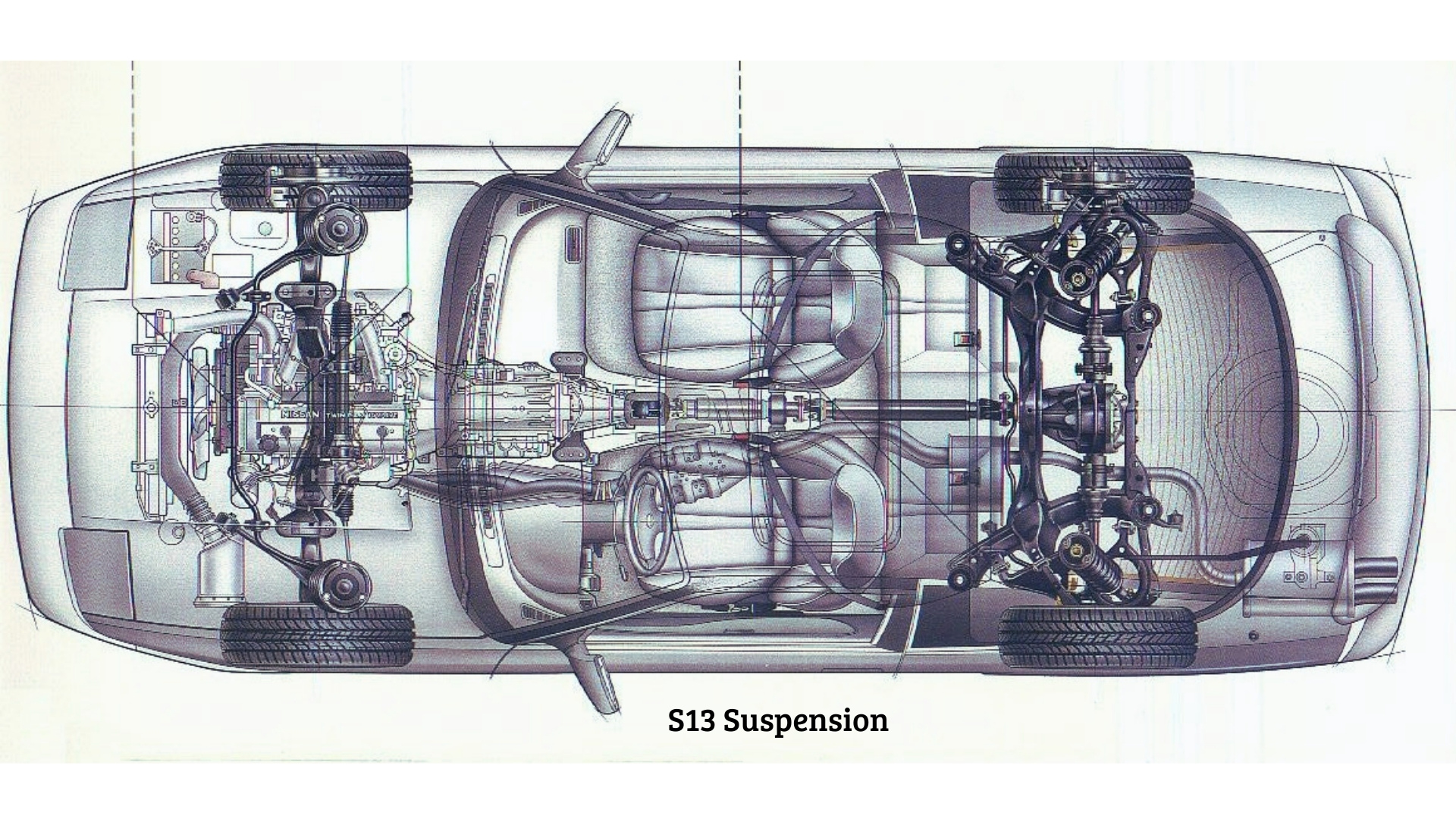

The 240SX employs a fully independent suspension system, a significant upgrade over older solid axle designs. This means each wheel can move independently of the others, allowing for better handling and ride quality. Both the front and rear suspensions utilize a multi-link configuration. This refers to a suspension design that uses multiple arms and links to control wheel movement. The specific multi-link setup differs between the front and rear, which we will examine in detail.

This independent system, in conjunction with a relatively light curb weight and a responsive chassis, contributes significantly to the 240SX's reputation for being a fun and engaging car to drive. The multi-link design allows for precise control of parameters like camber, caster, and toe, all of which are critical for optimizing handling performance. We will define these terms later.

Technical Breakdown of the Front Suspension

The front suspension of the 240SX uses a strut-based multi-link design. Let's break down the components:

- MacPherson Strut: The foundation of the front suspension. A strut is a combined spring and shock absorber unit. The spring provides support and absorbs bumps, while the shock absorber dampens oscillations to prevent the car from bouncing excessively. The strut also acts as a structural component, contributing to the car's overall rigidity.

- Lower Control Arm (LCA): The LCA connects the bottom of the strut to the chassis. It's a crucial component that dictates the lower pivot point of the wheel. The LCA on the 240SX is typically made of stamped steel.

- Tension Rod: This rod runs from the LCA to a mounting point further forward on the chassis. Its primary function is to control caster. Caster is the angle of the steering axis relative to vertical, viewed from the side of the car. Positive caster provides stability and helps the steering wheel return to center after a turn. The tension rod is adjustable in many aftermarket offerings, allowing for fine-tuning of caster settings.

- Sway Bar (Anti-Roll Bar): A torsion spring that connects the left and right sides of the suspension. Its purpose is to reduce body roll during cornering. When one wheel moves upward during a turn, the sway bar twists and transfers some of that force to the opposite wheel, helping to keep the car flatter.

- Steering Knuckle/Hub Assembly: This is where the wheel bearings, brakes, and steering components are mounted. It connects to the strut and the LCA.

- Tie Rods: Connect the steering rack to the steering knuckle. They transmit steering inputs from the steering wheel to the wheels, controlling toe. Toe refers to the angle of the wheels relative to each other, as viewed from above. Toe-in means the front of the wheels are closer together than the rear, while toe-out means the opposite.

Technical Breakdown of the Rear Suspension

The rear suspension of the 240SX utilizes a more complex multi-link design. This complexity allows for superior control over wheel geometry throughout the suspension travel.

- Upper Control Arm (UCA): This arm connects the top of the hub to the chassis. It primarily influences camber. Camber is the angle of the wheel relative to vertical, viewed from the front or rear of the car. Negative camber means the top of the wheel is tilted inward, which is often desirable for improved cornering grip.

- Lower Control Arm (LCA): Similar to the front, the LCA connects the bottom of the hub to the chassis. It contributes to overall stability and wheel positioning.

- Traction Rod (Toe Control Arm): This arm is dedicated to controlling toe. It's often adjustable in aftermarket configurations. Fine-tuning toe in the rear can significantly affect handling characteristics, especially during drifting.

- Rear Knuckle/Hub Assembly: This is where the wheel bearings and brakes are mounted. It connects to all the rear suspension arms.

- Coilover: In the rear, the spring and shock absorber are typically separate units. An aftermarket coilover setup combines the spring and shock into a single adjustable unit, allowing for ride height and damping adjustments. Some setups use a divorced spring and shock arrangement, where the spring sits on the LCA, and the shock is mounted separately.

- Sway Bar (Anti-Roll Bar): Functions identically to the front sway bar, reducing body roll during cornering.

Common Issues and Maintenance Concerns

Given the age of most 240SXs, several common issues can arise with the suspension:

- Worn Bushings: The rubber bushings in the control arms, tension rods, and sway bar links deteriorate over time, leading to sloppy handling, noise, and vibrations. Replacing these bushings with polyurethane bushings can improve handling but may also increase noise and harshness.

- Ball Joint Failure: Ball joints are critical components that allow the suspension to move smoothly. They can wear out and develop play, causing clunking noises and potentially leading to dangerous situations if they fail completely. Regularly inspect ball joints for signs of wear, such as excessive play or torn boots.

- Leaking Shock Absorbers: Shock absorbers lose their damping ability over time as the seals wear out and the fluid leaks. This results in a bouncy ride and reduced handling performance.

- Bent or Damaged Suspension Arms: Accidents or even hitting potholes can bend or damage suspension arms, affecting alignment and handling.

- Rust: Rust can weaken suspension components, particularly in areas with harsh winters. Thoroughly inspect the suspension for rust, especially around mounting points.

- Stripped Threads: Due to age and frequent adjustments, threads on suspension components can become stripped, making adjustments difficult or impossible.

Do's and Don'ts / Best Practices

Here are some best practices for maintaining and modifying your 240SX suspension:

- Do: Regularly inspect all suspension components for wear and tear. Pay close attention to bushings, ball joints, and shock absorbers.

- Do: Replace worn or damaged components promptly. Don't delay repairs, as worn suspension parts can negatively affect handling and safety.

- Do: Use quality replacement parts. Cheap aftermarket parts may not last as long or perform as well as OEM or reputable aftermarket brands.

- Do: Get a professional alignment after any suspension work, including replacing bushings, installing coilovers, or adjusting ride height. A proper alignment is crucial for optimal handling and tire wear.

- Do: Use a torque wrench when tightening suspension components. Overtightening can damage threads or stress components, while undertightening can lead to loosening and failure. Refer to the factory service manual for torque specifications.

- Don't: Lower your car excessively without considering the effects on suspension geometry. Excessive lowering can lead to bump steer, reduced suspension travel, and increased stress on other components. Roll center adjusters may be needed to correct geometry after significant lowering.

- Don't: Neglect maintenance. Regular lubrication of ball joints and other moving parts can extend their lifespan.

- Don't: Mix and match suspension components haphazardly. Ensure that all components are compatible and designed to work together. For example, using overly stiff springs with weak shocks can result in poor handling.

- Don't: Attempt suspension work if you are not comfortable or lack the necessary tools and knowledge. Suspension work can be dangerous if not performed correctly. Consult a qualified mechanic if needed.

Conclusion

The Nissan 240SX's suspension system is a key contributor to its reputation as a fun and engaging car. By understanding the basic principles of operation, common issues, and best practices for maintenance and modification, you can ensure that your 240SX continues to handle well for years to come. Regular inspection and preventative maintenance are paramount, especially given the age of these vehicles. If you plan on modifying the suspension, research thoroughly and choose quality components to achieve your desired handling characteristics without compromising safety. Investing in a quality suspension setup and professional alignment is a worthwhile investment for any 240SX enthusiast.