Nissan Made In What Country

Alright, let's dive into a question that might seem straightforward but quickly reveals itself to be surprisingly complex: Where are Nissans actually made? The short answer is: it's complicated! Nissan is a global brand with manufacturing plants scattered across the globe. No single country can claim to be the exclusive "home" of Nissan production. Think of it more as a distributed network, each plant contributing components and even complete vehicles for various markets.

The Japanese Foundation

It's impossible to talk about Nissan without acknowledging its roots. Nissan Motor Co., Ltd. was founded in Japan in 1933. So, Japan remains a critical hub for Nissan's operations, housing its corporate headquarters, research and development centers, and several key manufacturing facilities. Let's look at some specific examples:

- Oppama Plant: Located in Yokosuka, this plant is a major production center for Nissan, often building popular models like the Nissan Leaf and other compact vehicles. It's highly automated and represents some of Nissan's most advanced manufacturing technology.

- Tochigi Plant: This is where the magic happens for some of Nissan's high-performance vehicles. The Tochigi plant is known for producing cars like the Nissan GT-R and Infiniti models. It often utilizes more specialized assembly techniques and has a reputation for high quality control.

- Kyushu Plant: Situated in Southern Japan, this plant focuses on a wide range of vehicles, including SUVs and light trucks. It's a high-volume production facility, demonstrating Nissan's capability to mass-produce cars efficiently.

- Yokohama Plant: While not exclusively a vehicle assembly plant anymore, Yokohama holds significant historical importance as one of Nissan's oldest facilities. It now concentrates on engine production and other powertrain components.

Even though Nissan has expanded its manufacturing footprint globally, these Japanese plants maintain a critical role in developing new technologies, producing high-end vehicles, and supplying essential components to other assembly lines around the world. Parts manufactured in Japan are often shipped to other Nissan plants for assembly into vehicles destined for different regional markets. This interconnectedness is a key aspect of Nissan's global production strategy.

North American Production: A Major Player

North America is a huge market for Nissan, and to cater to this demand, Nissan has invested heavily in manufacturing facilities in the United States and Mexico. The Nissan Smyrna and Canton plants in the United States are particularly noteworthy.

Nissan Smyrna Assembly Plant (Tennessee, USA)

This is one of Nissan's largest manufacturing facilities globally. It's a sprawling complex capable of producing hundreds of thousands of vehicles annually. Smyrna is currently producing models such as:

- Nissan Altima

- Nissan Rogue

- Nissan Pathfinder

- Nissan Leaf (electric vehicle)

Nissan Canton Vehicle Assembly Plant (Mississippi, USA)

The Canton plant plays a vital role in producing trucks and SUVs for the North American market. It manufactures the following models:

- Nissan Titan

- Nissan Armada

- Nissan Frontier

The establishment of these US plants reflects Nissan's strategy to reduce transportation costs, respond quickly to market demands, and potentially benefit from trade agreements. These plants also generate significant employment opportunities in their respective regions. It is also important to note that the domestic content of vehicles produced in the US is a significant factor that affects tariffs and trade regulations.

Nissan Mexicana (Mexico)

Nissan has multiple manufacturing facilities in Mexico, playing a crucial role in supplying vehicles not just to the Mexican market, but also to other countries in North and South America. Key locations include:

- Aguascalientes A1 and A2: These plants are modern, high-volume facilities. A1 Plant produces the Nissan Sentra, while A2 Plant focuses on vehicles like the Nissan Kicks.

- Cuernavaca: This is one of Nissan's oldest plants in Mexico.

The Mexican plants offer Nissan a competitive advantage due to lower labor costs and proximity to the US market. Many vehicles assembled in Mexico are exported to the United States and other countries under free trade agreements, like the USMCA (United States-Mexico-Canada Agreement).

European Operations: Sunderland and Beyond

Nissan also has a significant presence in Europe, with the Sunderland plant in the United Kingdom being a major production hub. This plant has a long history of producing Nissan vehicles for the European market.

Nissan Motor Manufacturing UK (Sunderland)

For many years, the Sunderland plant produced a range of vehicles, including the Nissan Qashqai and the Nissan Juke. However, Nissan has recently adjusted its strategy for the Sunderland plant, focusing on electric vehicle (EV) production. The Sunderland plant is now a key part of Nissan's plan to expand its EV production capacity in Europe. Note that in 2024, Nissan officially announced a £1.4 billion investment for EV36Zero, a flagship EV hub at Sunderland.

The complexities of Brexit have undoubtedly influenced Nissan's decisions regarding its European operations, impacting supply chains, tariffs, and overall business strategy. The UK plant is adapting to these changes by focusing on EV production and leveraging its established infrastructure.

Asian Expansion: China and Beyond

Asia is a huge and growing market for automobiles, and Nissan has invested heavily in establishing manufacturing facilities in China, India, and other countries in the region. China, in particular, is a critical market for Nissan.

Dongfeng Nissan Passenger Vehicle Company (China)

Nissan has a joint venture with Dongfeng Motor Group in China, producing a wide range of vehicles specifically tailored to the Chinese market. These include models like the Nissan Sylphy and other sedans and SUVs. The Chinese market has unique demands and preferences, and Nissan designs and produces vehicles specifically for this region. The joint venture allows Nissan to navigate the complexities of the Chinese market and leverage local expertise.

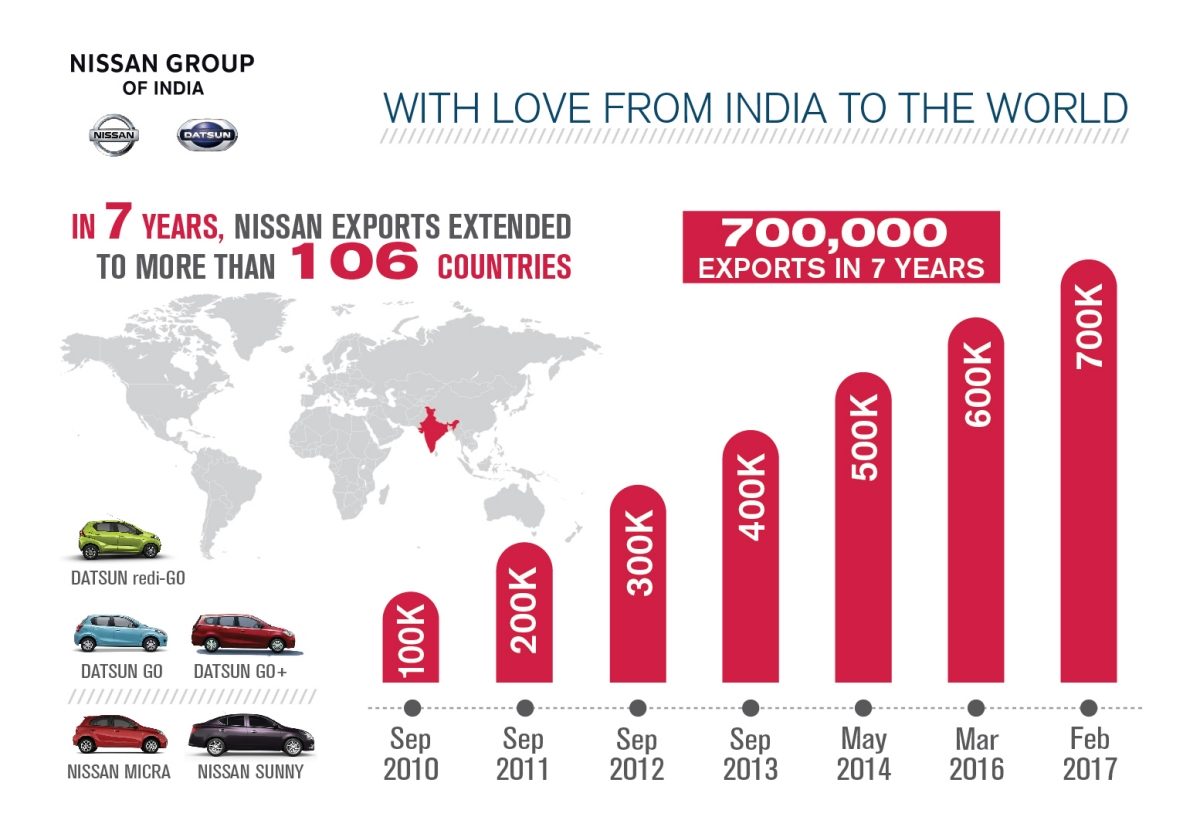

Aside from China, Nissan also has manufacturing operations in countries like India, Thailand, and Indonesia, catering to regional demand and potentially exporting vehicles to other markets in Asia and beyond. These plants produce a range of vehicles, from small cars to SUVs and light trucks.

The Global Supply Chain and Component Sourcing

It's important to remember that even if a vehicle is "made" in a particular country, it doesn't necessarily mean that all of its components originate from that same country. The automotive industry relies on a complex global supply chain, with parts and components sourced from various countries around the world. Engine blocks might be cast in one country, transmissions assembled in another, and electronic components sourced from yet another. The final assembly of the vehicle simply represents the culmination of this global process.

For example, a Nissan Rogue assembled in the USA might contain engine components manufactured in Japan, electronic control units (ECUs) from Germany, and tires from South Korea. The origin of these components is often indicated by markings on the parts themselves, and the manufacturer is required to disclose certain information about the origin of components for vehicles sold in specific markets. This disclosure typically takes the form of a "parts content label," which you can often find on the vehicle's window or doorframe.

Decoding the VIN: A Clue, Not the Whole Story

The Vehicle Identification Number (VIN) can provide some clues about the vehicle's origin, but it's not a definitive answer to the question of where a car is "made." The first character of the VIN indicates the country of origin of the manufacturer. For example:

- J: Japan

- 1 or 4: United States

- 3: Mexico

- W: Germany

However, the VIN only tells you where the manufacturer is based, not necessarily where the vehicle was assembled. For instance, a Nissan Rogue with a VIN starting with "1" (indicating the United States) might still contain a significant percentage of parts sourced from other countries. The VIN is a useful piece of information, but it should not be considered the definitive answer.

Conclusion

So, where is your Nissan made? The answer depends on the specific model and the market it was intended for. It's a global story, involving manufacturing plants spread across multiple continents and a complex web of suppliers. By understanding the role of different Nissan facilities around the world, the global supply chain, and the information contained in the VIN, you can get a clearer picture of the origins of your vehicle. And remember, the location of final assembly is only one piece of the puzzle. The true story of a Nissan's creation is a testament to the interconnectedness of the modern automotive industry.