Temp Gauge Not Working And Ac Not Working

Diagnosing a simultaneous failure of the temperature gauge and air conditioning system in a vehicle can be a frustrating experience. While seemingly unrelated, these issues can sometimes stem from shared components or underlying electrical problems. This article delves into the technical aspects of this combined failure, examining potential causes, diagnostic strategies, and best practices for repair.

Understanding the Interconnections

Although a direct mechanical link is rare, the electrical systems governing both the temperature gauge and the AC system often share a common ground, power supply, or even sensor input that is processed by the Engine Control Unit (ECU). For example, many vehicles employ an engine coolant temperature (ECT) sensor not only for gauge reading but also as a critical input for the ECU to determine AC compressor enablement. If the ECU perceives an overheating condition (real or false due to a faulty sensor), it will often disengage the AC compressor to prevent further engine strain.

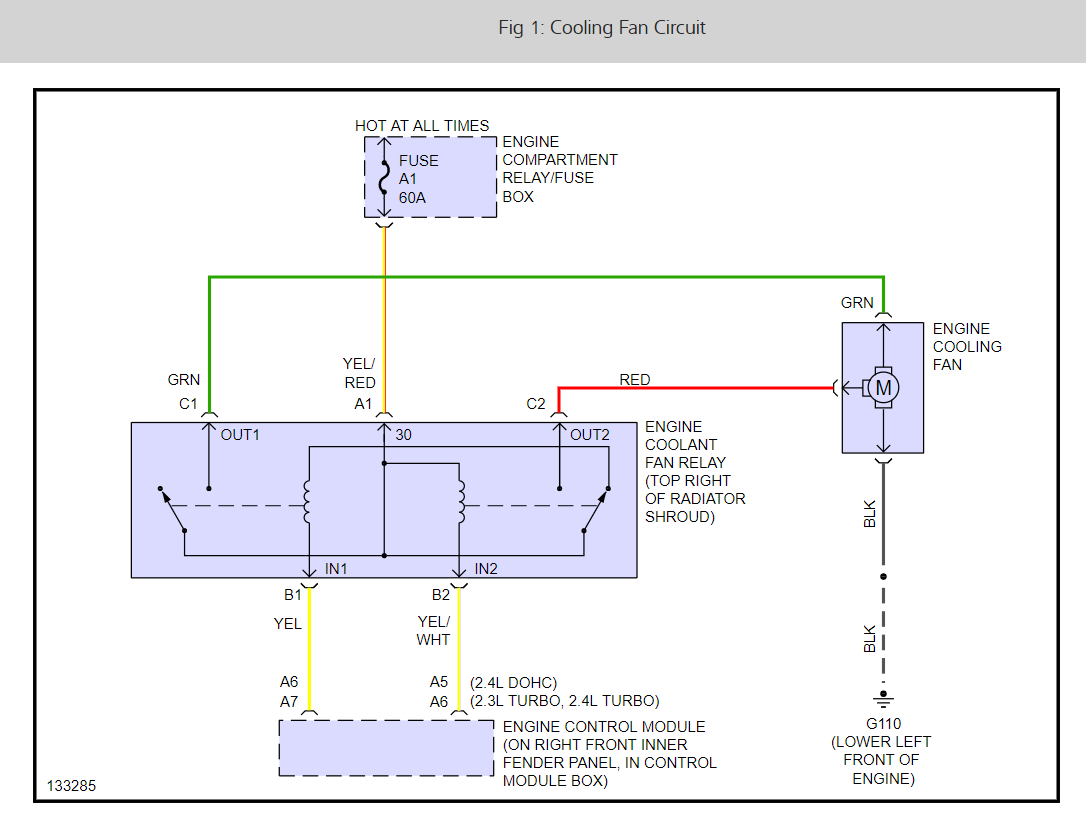

Wiring harnesses are another common point of failure. A damaged harness, especially one traversing the engine bay, can suffer from corrosion, abrasion, or rodent damage, impacting multiple circuits simultaneously. Grounding issues, too, can manifest in seemingly unrelated system malfunctions. A poor ground can lead to erratic voltage readings and unreliable sensor data, disrupting both the temperature gauge and AC functionality.

Potential Causes and Diagnostic Strategies

Here's a breakdown of the common culprits:

- Faulty ECT Sensor: As mentioned, the ECT sensor provides vital data to both the gauge and the ECU. An open circuit, short circuit, or inaccurate reading will impact both systems. Diagnosis involves checking the sensor's resistance value against the manufacturer's specification at different temperatures. A scan tool can display the live data stream from the sensor, providing further insight into its performance.

- Low Refrigerant: While not directly impacting the temperature gauge, low refrigerant pressure will prevent the AC compressor from engaging. Many systems use a pressure switch to protect the compressor from running dry. Diagnosis involves checking the refrigerant pressure using a manifold gauge set.

- Compressor Clutch Issues: The AC compressor clutch engages the compressor to the engine. A faulty clutch coil, relay, or wiring can prevent engagement. Testing involves verifying power and ground to the clutch and checking the coil's resistance.

- Blower Motor Problems: A malfunctioning blower motor won't circulate air, making the AC ineffective. This is usually a separate issue but can sometimes be related to electrical problems affecting other systems. Testing involves checking the blower motor's power and ground, as well as the blower motor resistor.

- Wiring and Grounding: Thoroughly inspect wiring harnesses for damage, corrosion, and loose connections. Use a multimeter to check for voltage drops and ground integrity. Pay close attention to grounding points, ensuring they are clean and secure.

- Faulty Thermostat: A stuck-open thermostat can prevent the engine from reaching operating temperature, impacting both the gauge reading and potentially AC performance (although this is less common than the other issues). Diagnosis involves visual inspection and checking engine temperature with a scan tool.

- Instrument Cluster Issues: In rare cases, the instrument cluster itself may be faulty, causing inaccurate readings for the temperature gauge. This often presents with other erratic gauge behavior. Diagnosis often involves replacing the cluster for testing purposes.

Engineering Choices and Alternatives

Modern vehicles increasingly rely on digital temperature gauges, displaying information processed by the ECU based on sensor input. Older vehicles often used analog gauges, directly connected to a sensor via a thermistor. Digital gauges offer greater accuracy and the ability to display warnings and diagnostic codes, but they are more susceptible to electronic failures. Analog gauges are simpler and more robust but less precise.

For AC systems, various compressor designs exist, including scroll, rotary, and piston types. Variable displacement compressors are increasingly common, offering improved efficiency by adjusting the compressor's output based on cooling demand. Alternatives to traditional refrigerant-based AC systems include thermoelectric coolers, but these are currently limited to niche applications due to their lower efficiency.

Reliability and Maintenance

Regular maintenance is crucial for preventing temperature gauge and AC system problems. This includes:

- Coolant Flushes: Maintaining clean coolant prevents corrosion and ensures accurate temperature readings.

- Refrigerant Top-Ups: Periodically checking and topping up refrigerant levels ensures optimal AC performance.

- Belt Inspections: Inspecting the AC compressor belt for wear and tear prevents slippage and potential failure.

- Electrical System Checks: Regularly inspecting wiring harnesses and grounding points can prevent corrosion and electrical problems.

The reliability of these systems depends heavily on the quality of components and the vehicle's operating environment. Exposure to extreme temperatures, harsh chemicals, and road salt can accelerate corrosion and component failure.

Future Trends

The automotive industry is moving towards more sophisticated climate control systems with advanced features such as zonal temperature control, air purification, and personalized settings. Electric vehicles (EVs) present unique challenges for thermal management, requiring efficient cooling for both the battery pack and the passenger cabin. Heat pumps are becoming increasingly common in EVs, offering improved energy efficiency for heating and cooling.

The increasing reliance on sensors and electronic control units will require automotive professionals to have a strong understanding of electrical diagnostics and data analysis. Advanced diagnostic tools and software will be essential for troubleshooting complex system failures. Predictive maintenance techniques, based on data analysis and machine learning, will likely play a more significant role in identifying potential problems before they lead to system failures.

In conclusion, diagnosing a combined temperature gauge and AC system failure requires a systematic approach, starting with a thorough understanding of the interconnections between these systems and a meticulous inspection of potential failure points. As vehicles become more complex, automotive professionals must adapt their skills and embrace new technologies to effectively diagnose and repair these sophisticated systems. The future of automotive repair lies in data-driven diagnostics and a holistic understanding of vehicle systems.