Turning Radius Of A Pickup Truck

The turning radius of a pickup truck is a crucial aspect of its maneuverability, impacting everything from parking in tight spaces to navigating off-road trails. Unlike smaller cars, trucks are known for their larger turning circles, which can be a source of frustration for drivers. This article delves into the factors affecting a pickup truck's turning radius, common problems that can arise, troubleshooting techniques, maintenance tips, and real-world issues encountered by truck owners and mechanics.

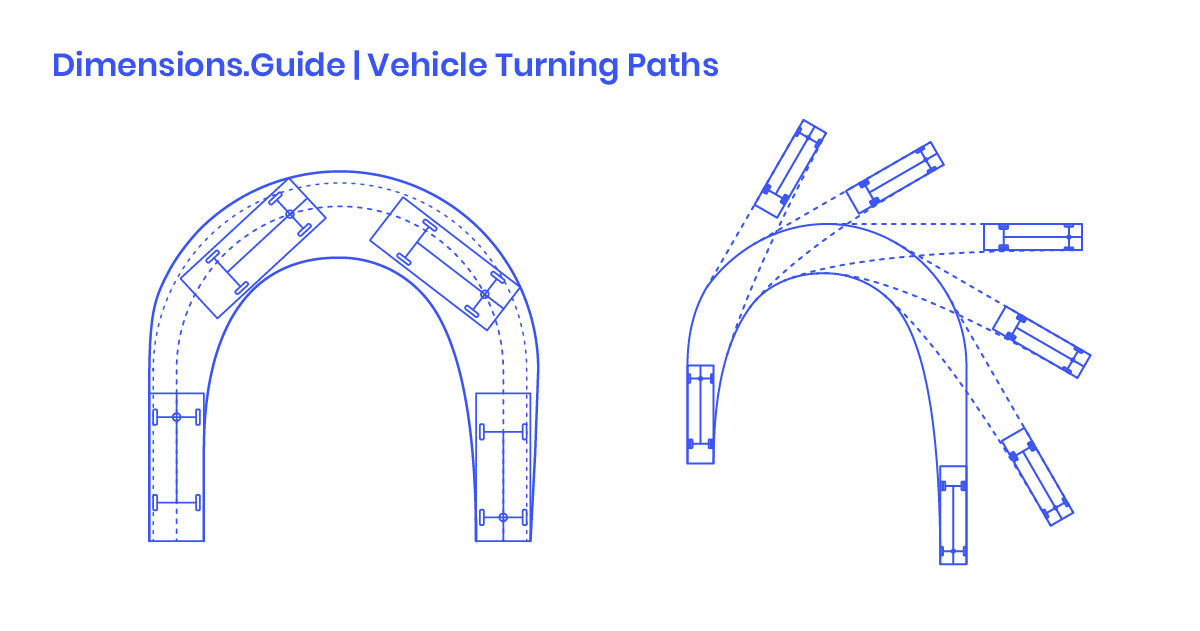

Understanding Turning Radius

The turning radius, also known as the turning circle, is the smallest diameter a vehicle can turn within. It's measured from the center of the turning circle to the outermost part of the vehicle. A smaller turning radius means the truck can make tighter turns, which is highly desirable in urban environments and challenging terrains. Several factors influence a pickup truck's turning radius:

- Wheelbase: Longer wheelbases invariably lead to larger turning radii. The distance between the front and rear axles directly impacts the truck's ability to pivot.

- Steering Geometry: The design and angles of the steering components, including tie rods, ball joints, and steering knuckles, play a crucial role.

- Suspension Setup: The type and configuration of the suspension system can affect how the wheels articulate during a turn.

- Tire Size: Larger tires, particularly those with aggressive treads, can sometimes increase the turning radius by interfering with the wheel wells or suspension components at full lock.

- Four-Wheel Drive (4WD) System: In some cases, the design of the 4WD system can slightly limit the turning radius compared to a two-wheel-drive (2WD) version of the same truck.

Common Problems and Troubleshooting

Several issues can manifest as a problem with a pickup truck's turning radius, making it feel wider than usual or causing unusual noises and vibrations during turns.

Symptom: Increased Turning Radius

Problem: Worn or Damaged Steering Components.

Cause: Over time, tie rod ends, ball joints, and other steering components can wear out due to constant stress, impacts from potholes, and exposure to the elements. This wear can introduce play in the steering system, reducing its effectiveness and increasing the turning radius.

Solution: Inspect the steering components for excessive play, looseness, or damage. A mechanic can use a pry bar to check for movement in the ball joints and tie rod ends. Replacement of worn or damaged components is necessary. After replacement, a wheel alignment is critical to ensure proper steering geometry.

Example: A Ford F-150 with over 100,000 miles experiencing a wider turning radius than usual may have worn ball joints. Replacing the ball joints and getting an alignment can restore the truck's original turning circle.

Problem: Improper Wheel Alignment.

Cause: Misalignment of the wheels, particularly toe-in or toe-out issues, can significantly affect the turning radius and steering response. This can occur due to hitting potholes, curb impacts, or simply wear and tear on suspension components.

Solution: A professional wheel alignment is the solution. Use a reputable alignment shop that uses modern equipment to ensure precise adjustments. Regular alignment checks are recommended, especially after off-road driving or any significant suspension work.

Example: A Chevrolet Silverado that has been driven off-road frequently might develop a wider turning radius due to a misaligned front end. An alignment can correct the problem.

Problem: Power Steering System Issues.

Cause: Problems with the power steering system, such as a low power steering fluid level, a failing power steering pump, or a leak in the system, can reduce the amount of assist available, making the steering feel heavier and increasing the perceived turning radius. It might also cause noise when turning.

Solution: Check the power steering fluid level and top it off if necessary. Inspect the power steering pump and hoses for leaks. If the pump is failing, it will need to be replaced. Address any leaks promptly to prevent further damage.

Example: A Ram 1500 experiencing a whining noise when turning, coupled with a heavy steering feel, likely has a power steering pump issue. Replacing the pump and flushing the system can resolve the problem.

Symptom: Noise During Turns

Problem: Binding or Interference.

Cause: This can be caused by modifications such as installing oversized tires or aftermarket suspension lifts without proper clearance. The tires might rub against the wheel wells, suspension components, or frame during turns, creating noise and restricting the turning radius.

Solution: Inspect the wheel wells, suspension components, and frame for signs of rubbing. Trimming the wheel wells or installing wheel spacers can provide additional clearance. Ensure that any modifications are compatible with the vehicle and properly installed.

Example: A Toyota Tacoma with a lift kit and larger tires might experience rubbing during turns. Trimming the wheel wells or using wheel spacers can address the issue.

Problem: Worn CV Joints (for 4WD Trucks).

Cause: Worn or damaged CV joints can cause clicking or popping noises during turns, especially at full lock. This indicates that the joints are failing and need to be replaced.

Solution: Inspect the CV joints for tears in the boots or signs of grease leakage. If noise is present, replacement is necessary. Address CV joint issues promptly to prevent further damage to the drivetrain.

Example: A Nissan Titan 4x4 experiencing clicking noises during turns likely has worn CV joints. Replacing the joints will eliminate the noise and restore smooth turning.

Symptom: Vibration During Turns

Problem: Uneven Tire Wear.

Cause: Uneven tire wear, often caused by misalignment or improper inflation, can lead to vibrations during turns. The uneven contact patch affects the vehicle's stability and handling.

Solution: Inspect the tires for signs of uneven wear, such as cupping, feathering, or excessive wear on one side. Correct any alignment issues, maintain proper tire pressure, and rotate the tires regularly to promote even wear.

Example: A GMC Sierra experiencing vibrations during turns may have uneven tire wear due to a worn suspension component causing improper alignment. Replacing the worn component and aligning the wheels will resolve the vibration.

Problem: Wheel Bearing Issues.

Cause: Worn or damaged wheel bearings can cause vibrations and humming noises during turns, as the bearing is under increased stress. The vibration often increases with speed.

Solution: Inspect the wheel bearings for play or noise. A mechanic can use a stethoscope to listen for bearing noise while the wheel is spinning. Replacement of worn wheel bearings is necessary to restore smooth and safe operation.

Example: A Ford Ranger experiencing a humming noise and vibrations during turns likely has a worn wheel bearing. Replacing the bearing will eliminate the noise and vibration.

Maintenance Tips for Optimal Turning Radius

Regular maintenance is crucial for maintaining a pickup truck's optimal turning radius and overall handling. Here are some essential tips:

- Regular Wheel Alignment: Get a wheel alignment check every 12,000 miles or annually, and after any significant suspension work.

- Tire Pressure Monitoring: Maintain proper tire pressure as specified in the owner's manual.

- Tire Rotation: Rotate the tires every 6,000-8,000 miles to promote even wear.

- Steering Component Inspection: Inspect the steering components (tie rod ends, ball joints, etc.) regularly for wear and tear.

- Power Steering System Maintenance: Check the power steering fluid level regularly and address any leaks promptly.

- Suspension System Inspection: Inspect the suspension components (shocks, struts, springs) for wear and damage.

- Lubrication: Lubricate the chassis components, including ball joints and tie rod ends, as recommended in the owner's manual.

Real-World Issues

Pickup truck owners often face real-world challenges related to turning radius, especially when using their trucks for work or recreation.

- Parking in Tight Spaces: The large turning radius can make parking in crowded urban areas difficult. Drivers may need to perform multiple maneuvers to get into a parking spot.

- Navigating Off-Road Trails: On narrow trails, the turning radius can limit maneuverability, requiring drivers to make wider turns or perform multi-point turns.

- Towing: Towing a trailer further increases the turning radius, making it even more challenging to navigate tight spaces.

- Construction Sites: Maneuvering in confined construction sites can be difficult with a large turning radius, requiring careful planning and execution.

Keeping Your Truck in Top Condition

To ensure your pickup truck remains in top condition and maintains its optimal turning radius, follow these recommendations:

- Adhere to the Maintenance Schedule: Follow the manufacturer's recommended maintenance schedule for all systems, including steering, suspension, and tires.

- Address Problems Promptly: Don't ignore warning signs such as noises, vibrations, or unusual handling. Address problems immediately to prevent further damage.

- Use Quality Parts: When replacing parts, use high-quality components that meet or exceed the manufacturer's specifications.

- Seek Professional Help: For complex repairs or troubleshooting, consult a qualified mechanic with experience working on pickup trucks.

- Proper Driving Habits: Avoid aggressive driving, hitting potholes, and curb impacts, as these can damage steering and suspension components.

By understanding the factors affecting a pickup truck's turning radius, recognizing common problems, and following proper maintenance practices, owners and mechanics can ensure that these vehicles remain maneuverable, safe, and reliable for years to come.