Wattage Of A Block Heater

The humble block heater, a stalwart companion in frigid climates for decades, might seem like a relic of the past, a quaint anachronism in our increasingly electrified automotive landscape. But before we consign it to the automotive history books, let’s take a closer look at its role – present and future – and how the fundamental principle it embodies: localized thermal management, is actually becoming more crucial than ever in the age of electric vehicles (EVs) and sophisticated hybrid systems.

The Traditional Block Heater: A Refresher

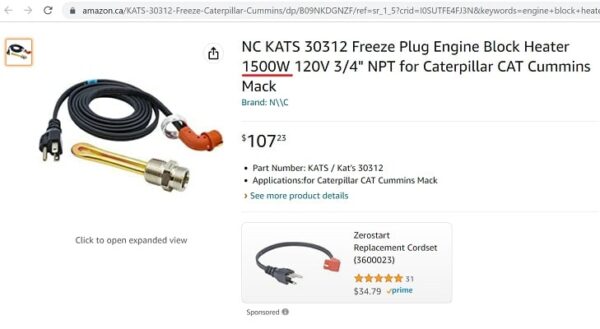

For those unfamiliar, a traditional block heater is essentially an electric resistance heater designed to warm the engine block of a combustion engine vehicle. Its primary purpose is to facilitate easier starting in cold weather. Cold temperatures significantly increase the viscosity of engine oil, making it harder for the starter motor to turn the engine over. A block heater combats this by pre-warming the oil and the engine components, ensuring smoother starts and reducing wear and tear, especially on older engines. While wattage varies, most block heaters fall in the range of 400 to 1500 watts. This relatively small power consumption can translate to significant benefits, including reduced emissions during initial start-up and improved fuel efficiency during the first few miles of driving.

The Electric Vehicle Paradox: Cold Weather Challenges

Now, here's where the interesting twist comes in. EVs, hailed as the future of sustainable transportation, aren't immune to the challenges of cold weather. In fact, they face unique hurdles that make thermal management even more critical than in internal combustion engine (ICE) vehicles. One of the biggest challenges is reduced battery range in cold temperatures. Battery chemistry is temperature-sensitive; low temperatures slow down the electrochemical reactions within the battery, reducing its capacity and its ability to deliver power effectively. This can translate to a range reduction of 20-40% in extremely cold conditions, a significant concern for EV owners.

Furthermore, heating the cabin of an EV is far less efficient than in an ICE vehicle. ICE vehicles generate waste heat from the engine, which can be readily used to warm the cabin. EVs, however, rely on electric resistance heaters or, more efficiently, heat pumps, to provide cabin heat. While heat pumps are significantly more energy-efficient than resistance heaters, they still draw power from the battery, further impacting range. This creates a conflict: drivers need cabin heat for comfort and safety, but using it significantly reduces their driving range. This is where the principles of the block heater, applied in a modern, sophisticated manner, can offer a viable solution.

Modern Thermal Management: The EV Block Heater Evolved

Instead of simply warming the engine block (which doesn't exist in an EV), modern thermal management systems for EVs focus on pre-conditioning the battery pack. This involves using a similar principle to the block heater – applying localized heating to bring the battery pack to its optimal operating temperature before the vehicle is driven. Several approaches are being explored:

- Integrated Battery Heaters: These are electric resistance heaters built directly into the battery pack. They can be activated via a timer, a smartphone app, or automatically based on ambient temperature. This allows the battery to be warmed while the vehicle is still plugged in, drawing power from the grid rather than depleting the battery.

- Liquid Cooling/Heating Systems: Many EVs use liquid cooling systems to regulate battery temperature. These systems can be adapted to circulate heated coolant through the battery pack in cold weather, pre-conditioning it for optimal performance.

- Heat Pumps with Advanced Controls: While heat pumps are already used for cabin heating, advancements in control algorithms and refrigerant technology are making them even more efficient and capable of providing both heating and cooling to the battery pack. The key is to optimize the system to prioritize battery temperature management when needed, even before cabin comfort.

The wattage requirements for these modern "EV block heaters" can vary depending on the battery pack size, the ambient temperature, and the desired pre-conditioning time. However, they are generally in a similar range to traditional block heaters, typically between 500 and 2000 watts. The important distinction is that the energy is being used far more effectively, directly impacting the performance and range of the EV.

Smart Automotive Solutions: Connectivity and Optimization

The true potential of these thermal management systems lies in their integration with smart automotive solutions. Imagine a scenario where your EV uses real-time weather data, your driving schedule, and your charging habits to intelligently pre-condition the battery.

For example:

- If the forecast predicts a frigid morning, the system automatically activates the battery heater an hour before your scheduled departure, ensuring optimal range.

- If you're planning a long trip, the system can proactively warm the battery before you unplug, maximizing range from the very beginning.

- The system can learn your driving patterns and adjust the pre-conditioning schedule accordingly, minimizing energy consumption while ensuring optimal performance.

This level of integration requires sophisticated software, advanced sensors, and seamless connectivity between the vehicle, the cloud, and your personal devices. It also raises important considerations about data privacy and cybersecurity. However, the potential benefits – increased range, improved performance, and enhanced convenience – are significant.

Hybrid Systems: A Bridge to the Future

Hybrid vehicles present a unique challenge and opportunity. They still have internal combustion engines, which can benefit from traditional block heaters. However, they also have electric motors and battery packs, which require thermal management similar to EVs. The ideal solution is an integrated thermal management system that can optimize the temperature of both the engine and the battery pack, maximizing fuel efficiency and electric range. This requires careful engineering and control algorithms that can intelligently allocate energy between the different components.

Looking forward, as hybrid systems become more sophisticated and incorporate larger battery packs, the emphasis will likely shift towards battery-centric thermal management. This means prioritizing the temperature of the battery pack to maximize electric range and performance, while still providing adequate warming for the engine to ensure smooth starting and efficient operation.

Realistic Challenges and Considerations

While the future of automotive thermal management is bright, several challenges need to be addressed. These include:

- Cost: Implementing advanced thermal management systems can add to the overall cost of EVs and hybrids. Balancing performance and efficiency with affordability is crucial.

- Complexity: Integrated thermal management systems are complex and require sophisticated engineering. Ensuring reliability and durability is essential.

- Energy Consumption: While pre-conditioning can improve range, it also consumes energy. Optimizing the system to minimize energy consumption is paramount.

- Infrastructure: Widespread adoption of EV pre-conditioning requires a robust charging infrastructure that can support the increased energy demand.

Overcoming these challenges will require collaboration between automakers, battery manufacturers, software developers, and policymakers. Investing in research and development, establishing industry standards, and providing incentives for the adoption of advanced thermal management technologies are all crucial steps.

The future of mobility is electric, connected, and autonomous. But it's also thermal. Efficiently managing temperature at a component level is not just about comfort or convenience; it's about maximizing performance, extending range, ensuring safety, and minimizing environmental impact.

A Visionary Note

Imagine a future where vehicles seamlessly adapt to their environment, using advanced thermal management to optimize performance and efficiency in any climate. Where batteries are pre-conditioned for optimal range, cabins are warmed or cooled intelligently, and energy is used with maximum efficiency. Where vehicles communicate with the grid and with each other, sharing information about weather conditions and energy demand to optimize thermal management strategies. This is not just a technological possibility; it's a necessary evolution in our quest for sustainable and efficient mobility. The humble block heater, in its modern, evolved form, will play a crucial role in this transformation, paving the way for a cleaner, greener, and more comfortable automotive future. A future where the principles of localized thermal management extend beyond just the engine or battery, optimizing the entire vehicle ecosystem for peak performance and efficiency.