What Are The Symptoms Of A Bad Ball Joint

The future of mobility is electric, connected, and increasingly autonomous. As we accelerate toward this exciting horizon, however, we can't forget the fundamentals. Even with self-driving cars on the horizon, the humble ball joint remains a critical component ensuring safe and reliable operation. Understanding the signs of a failing ball joint, especially in the context of new vehicle technologies, is more important than ever.

Traditional Symptoms in a New Era

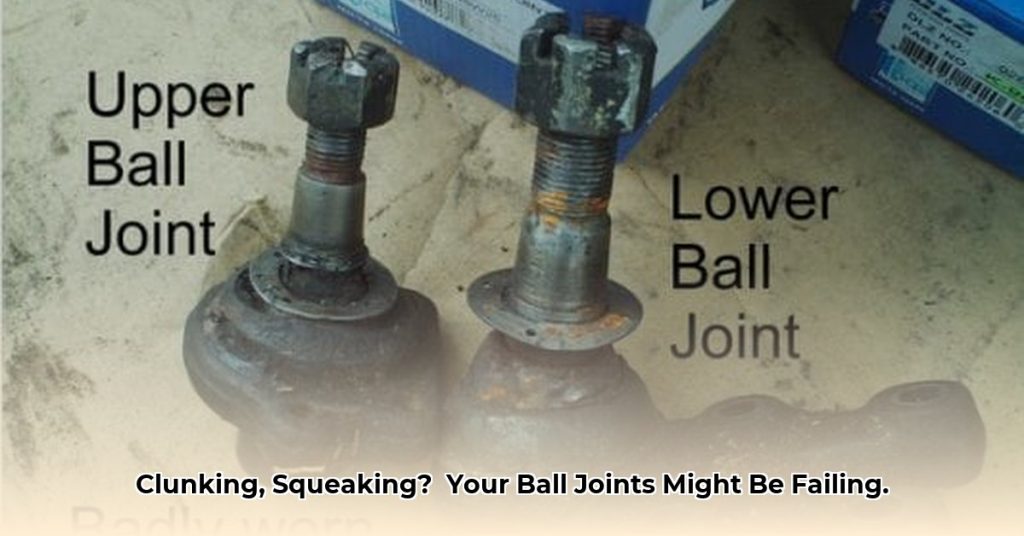

The classic symptoms of a bad ball joint still apply, but their presentation can be subtly different in modern vehicles. Clunking or popping noises, especially when going over bumps or turning at low speeds, are a primary indicator. This noise often originates from the suspension area where the ball joint is located. It signifies excessive play or looseness within the joint itself. As suspensions become more sophisticated with active dampening and air ride systems (increasingly common in EVs), this noise might be masked initially or be misinterpreted as a problem with the more complex damping mechanism itself. A keen ear and a knowledge of potential failure points is crucial.

Another common symptom is wandering steering. This occurs when the vehicle has difficulty maintaining a straight line and requires constant steering corrections. In electric vehicles (EVs) with their instant torque delivery and often lower center of gravity, this wandering might be less pronounced initially. However, the increased weight of EV battery packs can exacerbate the wear on ball joints, leading to a quicker deterioration and potentially more dangerous handling issues down the line. Hybrid vehicles, with their added complexities in weight distribution and regenerative braking systems, also place unique stresses on suspension components.

Uneven tire wear is another telltale sign, specifically on the inside or outside edges of the tires. This is due to the misalignment caused by the worn ball joint affecting the vehicle's camber and toe angles. Tire wear is costly, and premature wear is not only a financial burden but also contributes to environmental concerns. Smart tire technologies, already emerging, will provide real-time data on tire pressure and wear patterns. Integrating this data with predictive maintenance systems that also monitor ball joint health could significantly reduce tire waste and improve vehicle safety.

Finally, vibrations in the steering wheel, particularly at higher speeds, can signal a ball joint issue. These vibrations might be subtle at first, but will progressively worsen as the joint deteriorates. Modern vehicles with advanced driver-assistance systems (ADAS) like lane keeping assist and adaptive cruise control rely heavily on precise steering inputs. A compromised ball joint can interfere with the proper functioning of these systems, potentially leading to dangerous situations. Imagine a self-driving car with a faulty ball joint! The consequences could be catastrophic, highlighting the vital role even seemingly simple components play in the future of autonomous driving.

The Impact of New Technologies

Electric vehicles, with their instant torque and heavy battery packs, present unique challenges for ball joints. The increased weight puts more strain on the suspension components, potentially accelerating wear. Furthermore, the regenerative braking systems in EVs can alter the load distribution during deceleration, potentially leading to unusual wear patterns. Predictive maintenance systems, utilizing sensor data from the ball joints themselves (temperature, vibration, displacement), are becoming crucial for identifying potential problems early. Imagine ball joints with integrated sensors continuously monitoring their health and transmitting data to the vehicle's central computer or even directly to the manufacturer. This proactive approach can prevent costly repairs and ensure optimal vehicle safety.

Hybrid systems also introduce added complexities. The combination of internal combustion engines and electric motors creates a unique set of operating conditions that can impact ball joint wear. The constant switching between power sources and the regenerative braking features can result in fluctuating loads on the suspension system. Understanding these unique stresses and designing ball joints that can withstand them is essential for the long-term reliability of hybrid vehicles.

Challenges and Opportunities

While the future of mobility is bright, several challenges remain. The increasing complexity of modern vehicles makes diagnosing ball joint problems more difficult. Technicians need specialized training and equipment to accurately assess the condition of these components, especially in EVs and hybrids. The shortage of skilled technicians is a growing concern, and investing in training programs is crucial to ensure the safe and reliable operation of future vehicles.

Furthermore, the demand for longer-lasting and more durable ball joints is increasing. Consumers expect their vehicles to last longer, and the extended warranties offered by manufacturers put pressure on suppliers to produce high-quality components. Material science advancements are playing a key role in this regard. The development of new alloys and coatings that can withstand higher loads and resist corrosion is essential for improving ball joint durability. Self-lubricating ball joints, reducing friction and wear, represent another promising avenue for innovation.

A Vision for the Future

The future of ball joints is intertwined with the broader evolution of automotive technology. We envision a world where ball joints are not just passive components but intelligent sensors providing real-time data on their own health and performance. This data will be integrated with predictive maintenance systems, allowing for proactive repairs and preventing breakdowns. Smart materials will automatically adjust their properties based on operating conditions, optimizing performance and extending lifespan. And ultimately, the humble ball joint, a seemingly simple component, will play a vital role in ensuring the safety, reliability, and sustainability of the vehicles that will shape our future.