What Is A Common Water To Coolant Mixture

The lifeblood of any internal combustion engine (ICE) isn't just gasoline; it's also the unsung hero circulating beneath the hood: the coolant. A common water to coolant mixture is more than just a fluid; it's a meticulously engineered recipe designed to regulate engine temperature, preventing catastrophic overheating and ensuring optimal performance. Traditionally, this recipe involves a blend of water, typically distilled or deionized to minimize mineral deposits, and a concentrate known as antifreeze or coolant.

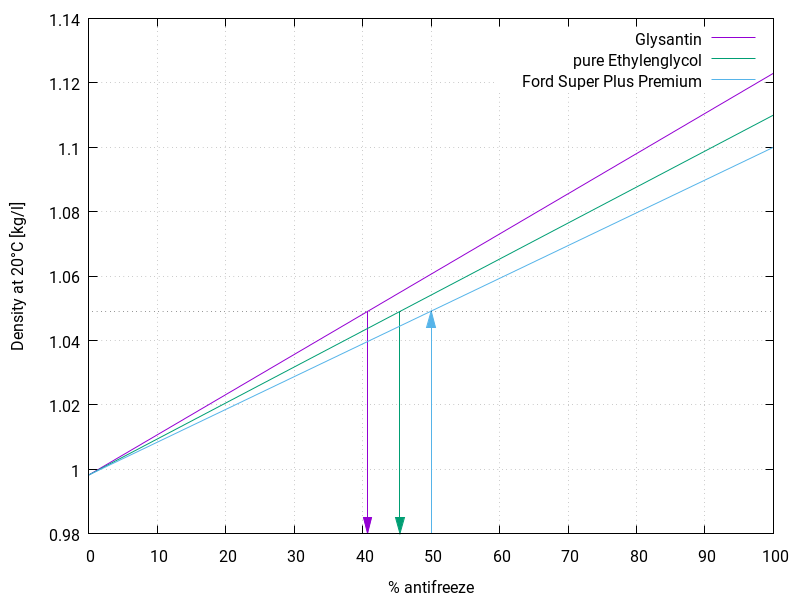

The ratio varies depending on the climate. In warmer regions, a 50/50 mix is often sufficient, providing adequate protection against boiling and corrosion. However, in colder climates, the ratio shifts towards a higher concentration of coolant, sometimes reaching 70/30 or even 60/40, to safeguard against freezing, which can crack engine blocks. This antifreeze component isn't just about preventing ice formation; it also contains vital additives to prevent corrosion of metal components within the cooling system, lubricate the water pump, and inhibit scale buildup.

The Evolving Role of Coolant in a Changing Automotive Landscape

The automotive industry is undergoing a seismic shift towards electrification. However, the relevance of coolant, and understanding the ideal water to coolant mixture, isn't diminishing; it's simply evolving. Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs) still require thermal management systems, albeit for different components. While they lack the intense heat generated by internal combustion, their battery packs, power electronics, and electric motors generate significant heat that needs to be dissipated effectively.

In EVs, coolant systems play a crucial role in maintaining optimal battery temperature. Overheating can lead to reduced battery lifespan, decreased performance, and even safety hazards. Therefore, EV coolant systems are often more sophisticated than those in traditional ICE vehicles, incorporating advanced sensors, pumps, and heat exchangers to precisely regulate temperature across different battery modules. Upcoming technologies are focusing on dielectric coolants, specialized fluids that are non-conductive and can directly cool battery cells, increasing efficiency and safety. These coolants may also incorporate nanomaterials to further enhance their thermal conductivity.

HEVs present a unique challenge, requiring coolant systems that can manage both the heat generated by the ICE and the thermal needs of the battery pack and electric motor. This necessitates a more complex system with multiple loops and control strategies. Furthermore, as hybrid powertrains become more sophisticated, with features like regenerative braking and advanced energy management systems, the demands on the cooling system will continue to increase.

Smart Automotive Solutions and Coolant Monitoring

Smart automotive solutions are also playing a crucial role in optimizing coolant management. Advanced sensor technology allows for real-time monitoring of coolant temperature, pressure, and even its chemical composition. This data can be used to predict potential problems, such as leaks or corrosion, and alert the driver or vehicle management system before they escalate into major issues. Predictive maintenance based on coolant analysis can significantly reduce downtime and extend the lifespan of cooling system components.

Moreover, connected car technology enables data sharing between vehicles and cloud-based platforms, allowing for fleet-wide monitoring of coolant performance. This can help identify trends, optimize coolant formulations, and even predict the optimal time for coolant replacement, reducing waste and environmental impact. Imagine a future where coolant formulations are tailored to specific vehicle types and driving conditions, maximizing efficiency and minimizing environmental footprint.

Challenges and Opportunities

Despite the advancements in coolant technology, several challenges remain. Developing coolants that are both highly effective and environmentally friendly is a crucial area of focus. Traditional antifreeze often contains ethylene glycol, a toxic substance that poses a risk to animals and humans. Research is underway to develop bio-based coolants and alternative formulations that are less harmful. The cost of advanced coolants and thermal management systems also presents a challenge, particularly for mass-market EVs and HEVs. Making these technologies affordable and accessible is essential for widespread adoption.

Furthermore, as vehicles become more complex, the integration of cooling systems with other vehicle systems, such as the powertrain, battery management system, and HVAC system, becomes increasingly critical. Optimizing the overall thermal management strategy requires a holistic approach that considers all aspects of vehicle operation. Standardization in testing and validation of new coolant technologies is also needed to ensure reliability and performance.

A Vision for the Future of Coolant

The future of coolant is one of intelligent thermal management, sustainable formulations, and seamless integration with advanced vehicle systems. Imagine coolants that can adapt to changing driving conditions, automatically adjusting their properties to optimize efficiency and performance. Envision self-healing coolants that can repair minor leaks and extend their lifespan. Consider a world where coolant is recycled and repurposed, minimizing waste and promoting a circular economy.

As mobility continues to evolve, the humble coolant will play an increasingly vital role in ensuring the efficiency, reliability, and sustainability of vehicles. The water to coolant mixture, although seemingly simple, will become a highly sophisticated and adaptable technology, driving the future of transportation. The evolution of this fundamental fluid reflects the broader transformation of the automotive industry, driven by innovation, sustainability, and a relentless pursuit of improved performance.