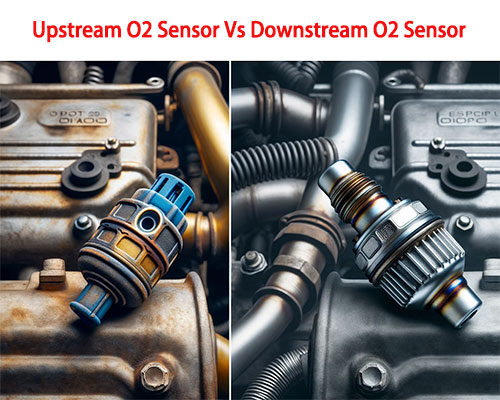

Whats The Difference Between Upstream And Downstream O2 Sensor

Oxygen sensors, often referred to as O2 sensors, are critical components in a modern vehicle's emission control system. They play a crucial role in monitoring the exhaust gases and providing feedback to the engine control unit (ECU) to optimize the air-fuel mixture. However, a vehicle typically doesn't just have one O2 sensor; it has multiple, strategically placed upstream and downstream of the catalytic converter. Understanding the difference between these sensors is paramount for proper diagnostics, maintenance, and repair.

Upstream O2 Sensor: Monitoring Engine Performance

The upstream O2 sensor, also known as the pre-catalytic converter O2 sensor, is positioned before the catalytic converter in the exhaust system. Its primary function is to measure the amount of oxygen in the exhaust gases coming directly from the engine's combustion process. This information is vital for the ECU to accurately control the air-fuel ratio.

Function and Operation

The upstream O2 sensor generates a voltage signal that varies depending on the oxygen content in the exhaust. A low voltage reading (near 0.1 volts) indicates a lean mixture (excess oxygen), while a high voltage reading (near 0.9 volts) indicates a rich mixture (insufficient oxygen). The ECU uses this feedback to adjust the fuel injectors, ensuring the engine operates at or near the ideal stoichiometric air-fuel ratio (typically 14.7:1 for gasoline engines).

There are two main types of upstream O2 sensors:

- Zirconia O2 sensors: These sensors are the most common type. They rely on a zirconium dioxide (ZrO2) ceramic element that generates a voltage when there's a difference in oxygen concentration between the exhaust gas and the ambient air. They require a certain operating temperature (around 600°F or 315°C) to function correctly, hence often featuring a built-in heating element for quicker activation.

- Titania O2 sensors: These sensors, less common than zirconia sensors, use titanium dioxide (TiO2). Instead of generating a voltage, they change their electrical resistance based on the oxygen concentration in the exhaust. The ECU monitors this resistance change to determine the air-fuel ratio.

Diagnostic Significance

The upstream O2 sensor provides crucial insights into the engine's performance. Issues such as:

- Vacuum leaks: Leading to a lean mixture.

- Faulty fuel injectors: Potentially causing either rich or lean conditions.

- Malfunctioning mass airflow (MAF) sensor: Causing incorrect air-fuel ratio calculations.

…can be detected by analyzing the upstream O2 sensor's signal. A slow or erratic upstream O2 sensor response can trigger a check engine light and indicate the need for sensor replacement or further engine diagnostics.

Example: Imagine a scenario where a car exhibits poor fuel economy and a rough idle. A diagnostic scan reveals codes related to the upstream O2 sensor. Upon closer inspection using a scan tool that displays live sensor data, it's observed that the upstream O2 sensor's voltage is fluctuating slowly and sporadically. This suggests the sensor is degrading and unable to provide accurate feedback to the ECU, resulting in improper air-fuel mixture control and the observed symptoms.

Downstream O2 Sensor: Monitoring Catalytic Converter Efficiency

The downstream O2 sensor, also known as the post-catalytic converter O2 sensor, is located after the catalytic converter in the exhaust system. Its primary purpose is not to control the air-fuel ratio, but to monitor the efficiency of the catalytic converter. It essentially checks if the catalytic converter is effectively reducing harmful emissions.

Function and Operation

The catalytic converter is designed to convert harmful pollutants like hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) into less harmful substances like carbon dioxide (CO2), water (H2O), and nitrogen (N2). If the catalytic converter is functioning correctly, the downstream O2 sensor's signal should be relatively stable and less fluctuating than the upstream sensor's signal.

The downstream O2 sensor's voltage should typically hover around a steady value, usually around 0.45 to 0.7 volts. This indicates that the catalytic converter is effectively "storing" oxygen and reducing the oxygen content in the exhaust gases passing through it.

Diagnostic Significance

The downstream O2 sensor is a key indicator of catalytic converter health. If the downstream O2 sensor signal starts to mimic the fluctuating signal of the upstream O2 sensor, it suggests that the catalytic converter is losing its efficiency and is no longer effectively converting pollutants. This can trigger a check engine light with codes indicating catalytic converter inefficiency (e.g., P0420 - Catalyst System Efficiency Below Threshold).

It's important to note that a faulty downstream O2 sensor itself can also trigger similar codes. Therefore, proper diagnosis is crucial to differentiate between a failing sensor and a failing catalytic converter.

Example: A vehicle owner experiences a check engine light and a diagnostic scan reveals a P0420 code. Examining the live data from both the upstream and downstream O2 sensors reveals that both sensors are exhibiting similar fluctuating voltage patterns. This strongly suggests that the catalytic converter is no longer effectively reducing emissions, and the downstream O2 sensor is simply reporting this inefficiency.

Key Differences Summarized

To recap the main differences, consider this table:

| Feature | Upstream O2 Sensor | Downstream O2 Sensor |

|---|---|---|

| Location | Before the catalytic converter | After the catalytic converter |

| Primary Function | Monitor air-fuel ratio for engine control | Monitor catalytic converter efficiency |

| Signal Pattern | Fluctuating, reflecting changes in air-fuel mixture | Relatively stable, indicating catalytic converter function |

| Impact of Failure | Poor engine performance, fuel economy issues | Check engine light, potential emissions failure |

Troubleshooting and Replacement

When troubleshooting O2 sensor issues, it's essential to use a diagnostic scan tool to read trouble codes and analyze live sensor data. This allows for a more accurate diagnosis and helps differentiate between sensor failures and other engine-related problems.

Replacing an O2 sensor is a relatively straightforward process for experienced mechanics and some knowledgeable car owners. However, it's crucial to:

- Use the correct sensor type: Ensure the replacement sensor is compatible with the vehicle's make, model, and engine.

- Disconnect the battery: To prevent electrical shorts.

- Use proper tools: An O2 sensor socket is essential for removing and installing the sensor without damaging it.

- Apply anti-seize compound: To the sensor threads to prevent future seizing.

After replacing the sensor, clear any stored trouble codes and monitor the sensor's performance using a scan tool to ensure it's functioning correctly.

Advanced O2 Sensor Technologies

Modern vehicles are increasingly employing more sophisticated O2 sensor technologies. Wideband O2 sensors, for instance, offer a wider measurement range and more accurate air-fuel ratio readings compared to traditional narrowband sensors. These sensors are often used in newer vehicles to meet stricter emission standards and improve fuel efficiency.

Some vehicles also utilize heated O2 sensors that reach their operating temperature much faster, allowing for more precise emission control even during cold starts. These advancements highlight the ongoing evolution of O2 sensor technology to meet the demands of modern engine management systems.

In conclusion, understanding the roles of both upstream and downstream O2 sensors is vital for diagnosing and resolving emission-related issues in modern vehicles. By recognizing the distinct functions of each sensor and utilizing appropriate diagnostic tools, technicians and car enthusiasts can effectively maintain and repair these crucial components, ensuring optimal engine performance and minimizing harmful emissions.