Why Does My Tire Pressure Keep Going Down

Understanding why tire pressure consistently drops is crucial for maintaining vehicle safety, optimizing fuel efficiency, and extending tire lifespan. This article delves into the common causes, technical details, and practical solutions for this pervasive automotive problem, targeting automotive professionals.

The Usual Suspects: Identifying Leaks

A gradual decrease in tire pressure often indicates a leak. Common culprits include:

- Punctures: Even small punctures from nails, screws, or road debris can create slow leaks. Inspect the tire's surface meticulously, both the tread and sidewalls. Look for embedded objects or signs of repair.

- Valve Stem Issues: The valve stem is a critical component. Rubber valve stems can degrade over time due to UV exposure and ozone, leading to cracks and leaks. Metal valve stems, while more durable, can corrode or become damaged at the seal with the wheel. The Schrader valve core itself can also loosen or become damaged, allowing air to escape. Torque specifications for valve stem installation are critical; over-tightening can damage the seal, while under-tightening allows leakage. Replacement is often the best course of action for suspect valve stems.

- Rim Leaks: Corrosion, damage, or improper seating of the tire bead against the rim can create leaks. Aluminum wheels are particularly susceptible to corrosion, especially in areas with road salt. Inspect the rim bead area for any signs of damage or corrosion. This often necessitates removing the tire for a thorough inspection and cleaning. Bead sealers can sometimes provide a temporary fix, but addressing the underlying issue is paramount.

- Tire Porosity: While less common with modern tire construction, some tires, particularly those with higher mileage or older compounds, can become slightly porous, allowing air to permeate through the rubber. This is more prevalent in tires with thinner sidewalls designed for performance applications.

Technical Deep Dive: Materials and Manufacturing

Tire construction involves multiple layers and compounds. The inner liner, typically a butyl rubber compound, is designed to be airtight. However, imperfections in the manufacturing process or damage to this layer can compromise its integrity. Modern tire manufacturing processes focus on minimizing porosity and ensuring uniform liner thickness. The quality of the rubber compound and the curing process significantly impact the tire's ability to retain air. Premium tire brands often invest in advanced materials and manufacturing techniques to enhance air retention.

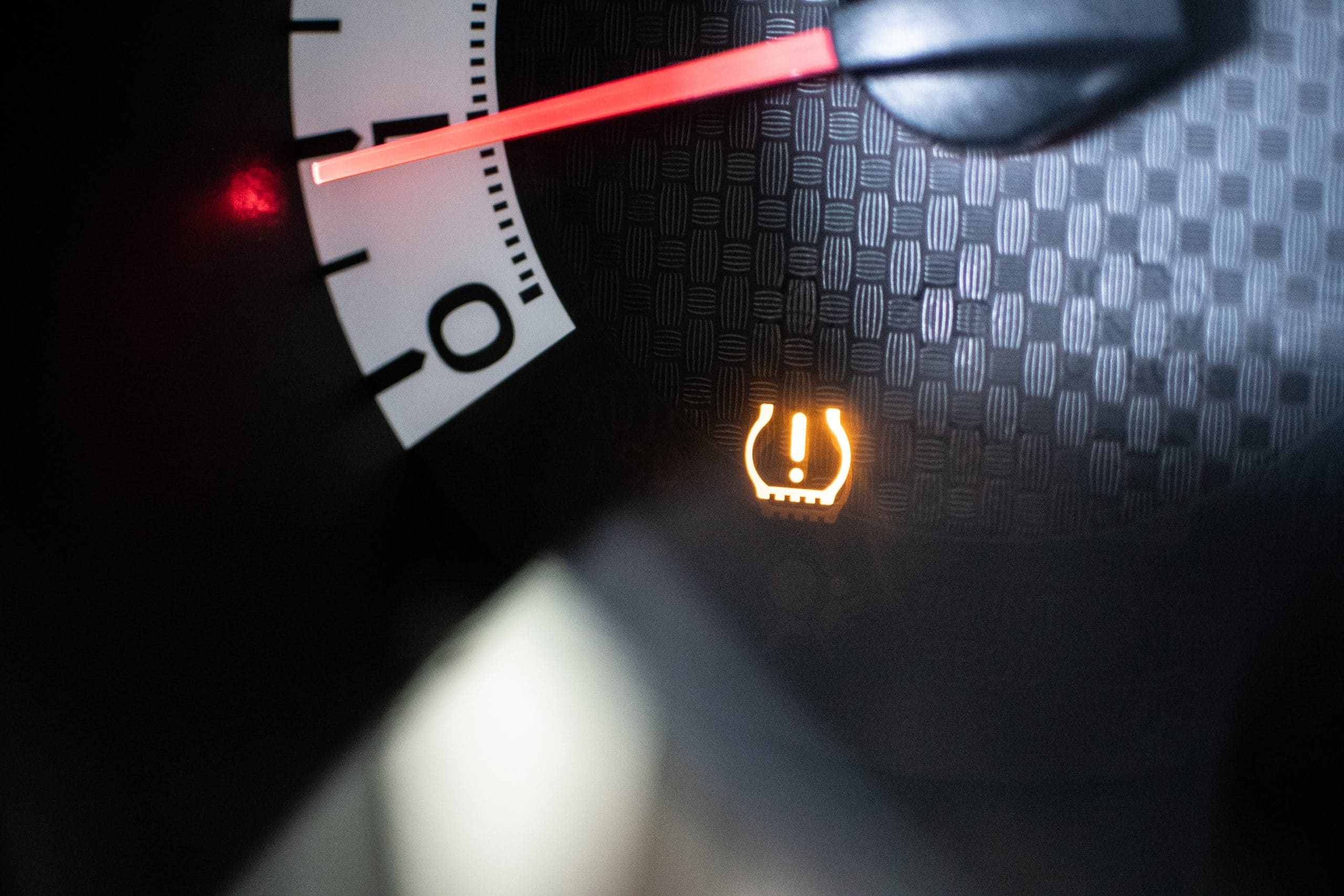

TPMS Considerations: Beyond Just Pressure Readings

Tire Pressure Monitoring Systems (TPMS) are now standard equipment, providing real-time pressure readings. However, TPMS sensors themselves can be a source of leaks. The seal between the sensor and the wheel can degrade over time, and the sensor's internal battery eventually needs replacement, requiring a re-seal. When diagnosing pressure loss, always inspect the TPMS sensor for leaks or damage. Furthermore, ensure the TPMS is properly calibrated and functioning correctly to provide accurate readings.

Real-World Performance and Environmental Factors

Ambient temperature significantly affects tire pressure. For every 10-degree Fahrenheit change in temperature, tire pressure changes by approximately 1 PSI. During colder months, pressure will naturally decrease, and during warmer months, it will increase. It's crucial to adjust tire pressure accordingly. Aggressive driving habits, such as hard cornering and braking, can also contribute to increased tire temperature and pressure fluctuations. Regular pressure checks, especially during seasonal transitions, are essential.

Alternatives and Their Pros and Cons: Nitrogen vs. Air

Nitrogen inflation is often touted as a solution for pressure loss. Pros: Nitrogen molecules are larger than oxygen molecules, theoretically reducing permeation through the tire. Nitrogen is also less susceptible to temperature-related pressure fluctuations. Cons: The actual difference in pressure loss is often marginal, and the cost of nitrogen inflation can be significant. Furthermore, the air we breathe is already approximately 78% nitrogen. Proper tire maintenance, regardless of the inflation gas, remains the most important factor. A slow leak will still occur regardless of whether the tire is filled with nitrogen or air.

Reliability and Maintenance: Best Practices

Here are some crucial maintenance tips for minimizing pressure loss:

- Regular Inspections: Visually inspect tires for punctures, cuts, and sidewall damage.

- Pressure Checks: Check tire pressure at least once a month and before long trips, using a reliable gauge.

- Proper Inflation: Inflate tires to the vehicle manufacturer's recommended pressure (found on the doorjamb sticker) – not the maximum pressure listed on the tire sidewall.

- Valve Stem Maintenance: Replace valve stems every few years, especially when replacing tires.

- Wheel Maintenance: Clean and inspect wheels for corrosion or damage.

- Professional Alignment: Ensure proper wheel alignment to prevent uneven tire wear and stress.

Future Trends: Smart Tires and Predictive Maintenance

The automotive industry is moving towards "smart tires" equipped with sensors that provide real-time data on pressure, temperature, tread depth, and even road conditions. These sensors can transmit data to the vehicle's onboard computer and even to the cloud, enabling predictive maintenance and early warning systems for potential tire issues. Imagine a future where your car automatically alerts you to a slow leak before it becomes a safety hazard. This technology will revolutionize tire maintenance and improve overall vehicle safety.

Looking Ahead

As vehicle technology continues to evolve, the role of automotive professionals will become increasingly complex. Staying informed about advancements in tire technology, TPMS systems, and diagnostic tools is essential for providing top-notch service and ensuring vehicle safety. Embracing these changes will be key to success in the evolving automotive landscape. The focus will shift from reactive repairs to proactive maintenance, driven by data and connectivity.