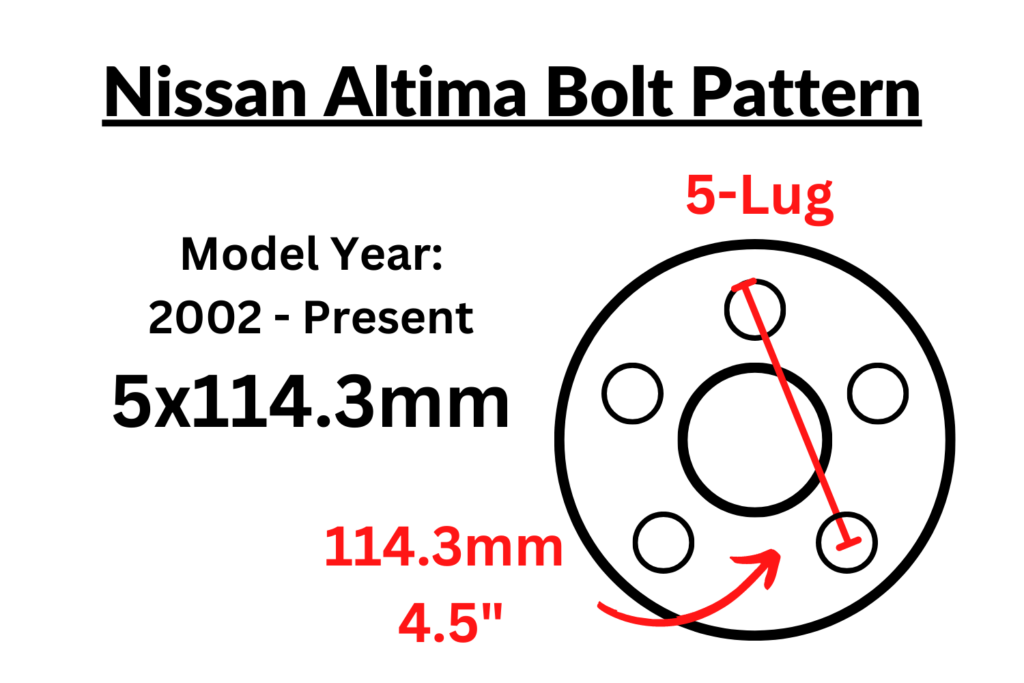

05 Nissan Altima Bolt Pattern

The 2005 Nissan Altima, a mainstay in the mid-size sedan market, boasts a relatively straightforward and common wheel bolt pattern: 5x114.3mm (or 5x4.5 inches). This specification dictates that the wheel hub has five studs arranged in a circle with a diameter of 114.3 millimeters (or 4.5 inches). Understanding this seemingly simple detail is crucial for automotive professionals, as it impacts everything from wheel and tire selection to suspension modifications and overall vehicle performance.

Technical Specifications and Engineering Choices

The 5x114.3mm bolt pattern wasn't a random choice by Nissan engineers. It represents a balance between several factors. First, it offers ample strength and stability for a vehicle of the Altima's size and weight. Five studs provide a secure and evenly distributed clamping force, minimizing the risk of wheel loosening or vibration, especially under demanding driving conditions. Secondly, it is a widely adopted standard, meaning a vast aftermarket selection of wheels is available, catering to a broad range of budgets and aesthetic preferences.

Engineering considerations also play a role in the selection of stud size and thread pitch, which, while not directly part of the bolt pattern, are intrinsically linked. Typically, the 2005 Altima utilizes a 12x1.25mm or 12x1.5mm stud size. The choice depends on the specific model and trim level. Automotive technicians must ensure that any aftermarket wheels or studs are compatible with the original specifications to guarantee proper fitment and prevent damage to the hub or wheel.

The center bore diameter is another important aspect to consider. It is the size of the hole in the center of the wheel that fits over the hub's center flange. The 2005 Altima typically uses a center bore diameter of 66.1mm. When installing aftermarket wheels, it's crucial that the center bore either matches this specification or is larger, requiring the use of hub-centric rings to ensure proper centering and reduce vibration. Ignoring the center bore can lead to wheel imbalance and premature bearing wear.

Real-World Performance and Comparison

The 5x114.3mm bolt pattern is incredibly common across a wide range of vehicles, from other Nissan models like the Maxima and Murano to vehicles from Toyota, Honda, and Ford. This shared standard simplifies parts availability and makes it easier to find suitable wheels for different applications. The widespread use of this bolt pattern also suggests a level of industry-wide acceptance for its performance characteristics.

Compared to alternatives, such as 4-lug or 6-lug patterns, the 5-lug configuration offers a better balance of strength and weight. A 4-lug design might be sufficient for lighter vehicles, but it may not provide adequate clamping force for a mid-size sedan like the Altima. Conversely, a 6-lug pattern, often found on trucks and SUVs, offers even greater strength but comes with the penalty of increased weight and complexity. The 5x114.3mm pattern strikes a sweet spot, providing sufficient strength for typical driving conditions while keeping weight manageable and parts readily available.

However, the 5x114.3mm pattern is not without its limitations. For extreme performance applications, such as high-horsepower racing or off-roading, a more robust bolt pattern like a 5x120mm or 6x139.7mm might be preferred. These larger patterns offer greater strength and are less prone to failure under extreme stress. But for the vast majority of Altima owners, who primarily use their vehicles for commuting and everyday driving, the 5x114.3mm pattern is perfectly adequate.

Pros and Cons

Pros:

- Wide Availability: Numerous wheel options are available from various manufacturers.

- Strength: Provides adequate clamping force for a mid-size sedan.

- Simplicity: Easy to understand and service.

- Cost-Effective: Relatively inexpensive to maintain and replace parts.

Cons:

- Limited Extreme Performance: Not ideal for high-horsepower racing or off-road applications.

- Potential for Confusion: Similar bolt patterns exist (e.g., 5x115mm), requiring careful verification.

Reliability Aspects and Maintenance Tips

The 5x114.3mm bolt pattern itself is inherently reliable. However, issues can arise if proper maintenance is neglected or if incompatible parts are used. Over-tightening lug nuts can damage the studs or warp the wheel hub. Under-tightening can lead to wheel loosening and, in extreme cases, wheel separation. It is crucial to use a torque wrench and tighten the lug nuts to the manufacturer's specified torque settings (typically around 80-90 ft-lbs for the 2005 Altima).

Regular inspection of the wheel studs and lug nuts is essential. Look for signs of corrosion, damage, or thread wear. Replace any damaged components immediately to prevent future problems. Anti-seize compound can be applied to the wheel studs to prevent corrosion and make future wheel removal easier, but it should be used sparingly to avoid over-torquing. It's imperative to recalibrate your torque wrench if using anti-seize, as it will affect the torque readings.

When rotating tires, always inspect the wheel hubs for signs of damage or wear. Check the hub bearings for play or noise. Replace any worn or damaged components promptly to maintain proper wheel alignment and prevent premature tire wear. Using hub-centric rings with aftermarket wheels can help to center the wheel properly and reduce vibration, extending the life of the bearings and tires.

Future Trends

While the 5x114.3mm bolt pattern remains prevalent, the automotive industry is constantly evolving. Electric vehicles (EVs) and hybrid vehicles are becoming increasingly common, and these vehicles often require different wheel designs to accommodate larger brakes, regenerative braking systems, and specific aerodynamic requirements. However, the 5x114.3mm bolt pattern is still being used in many newer vehicles, albeit with variations in offset and wheel diameter.

Furthermore, advancements in materials and manufacturing processes are leading to the development of stronger and lighter wheels. This may allow for the use of alternative bolt patterns in the future, potentially optimizing wheel strength and weight for specific applications. Digital torque wrenches with built-in angle measurement are also becoming more common, ensuring more accurate and consistent lug nut tightening.

The rise of aftermarket modifications and customization is also influencing wheel design. Owners are increasingly seeking unique and personalized wheels to enhance the appearance of their vehicles. This trend is driving innovation in wheel design and manufacturing, leading to a wider variety of styles and finishes.

Forward-Looking Note

The automotive industry is undergoing a period of unprecedented change, driven by technological advancements, environmental concerns, and shifting consumer preferences. Electric vehicles, autonomous driving, and connected car technologies are transforming the way we design, manufacture, and use automobiles. Automotive professionals must stay abreast of these changes to remain competitive and provide the best possible service to their customers. Understanding seemingly simple details like wheel bolt patterns, along with more complex systems, is crucial for navigating this evolving landscape and ensuring the safety, performance, and reliability of the vehicles we service.