07 Nissan Altima Bolt Pattern

Alright, let's dive into the wheel bolt pattern for the 2007 Nissan Altima. Understanding this is crucial if you're planning on replacing your wheels, upgrading to aftermarket rims, or even just replacing a stud. Getting it wrong can be a costly and potentially dangerous mistake, so let's get it right.

Understanding Bolt Patterns

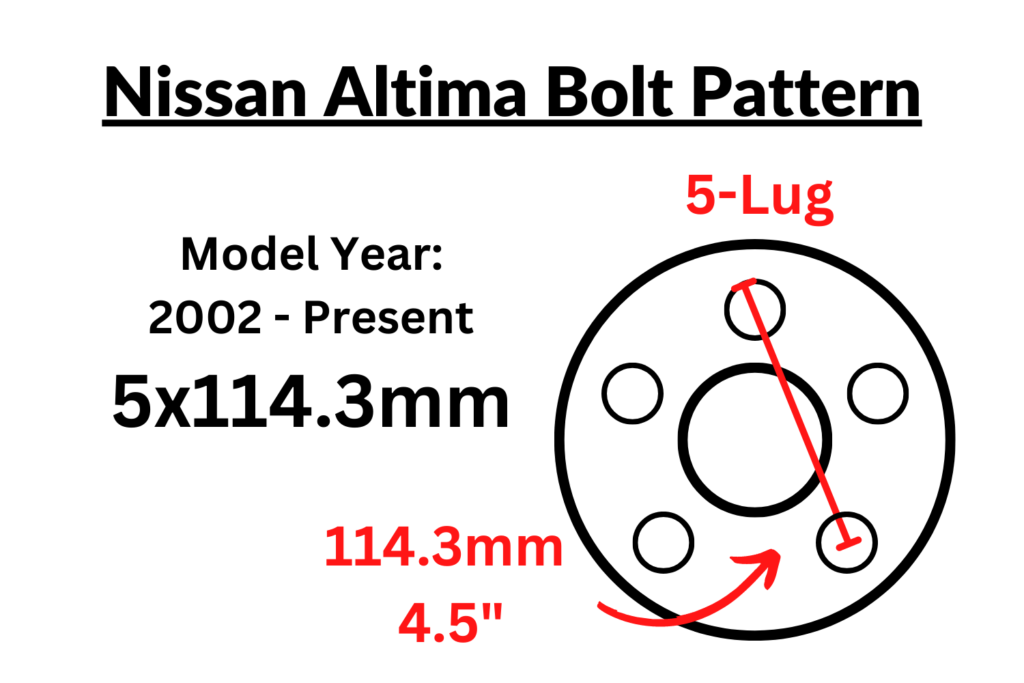

First things first, what *is* a bolt pattern? Simply put, it's the measurement that describes how the lug nuts or bolts are arranged on your wheel hub. It's expressed as two numbers, like "5x114.3". The first number indicates the number of lug nuts or bolts securing the wheel, while the second number is the diameter of the circle these fasteners are arranged on, usually measured in millimeters.

The 2007 Altima Bolt Pattern: The Specifics

The 2007 Nissan Altima uses a 5x114.3mm (or 5x4.5") bolt pattern. Let's break that down:

- 5: This means your Altima has 5 lug nuts (or bolts, though lug nuts are standard on the Altima) securing each wheel.

- 114.3mm (4.5"): This is the pitch circle diameter (PCD). Imagine a circle running through the center of each of those 5 lug nut holes. The diameter of that imaginary circle is 114.3 millimeters, which is equivalent to 4.5 inches.

It's critical to remember both numbers. Using a wheel with the wrong bolt pattern, even if it *looks* close, can result in the wheel not seating correctly against the hub, leading to loose lug nuts, vibrations, and eventually, catastrophic wheel failure. You don't want your wheel coming off while you're driving!

Verifying the Bolt Pattern

While I've told you the standard bolt pattern, it's always a good idea to double-check, especially if your Altima has been modified or if you are unsure of its history. Here are a few methods to verify it:

- Owner's Manual: The owner's manual is a good starting point. It *should* list the wheel specifications, including the bolt pattern.

- Wheel Markings: Some wheels have the bolt pattern stamped on the back. Remove a wheel and carefully inspect the inner surface.

- Online Databases: There are numerous online databases that allow you to look up the bolt pattern by vehicle make, model, and year. Be sure to use a reputable source.

- Measuring Manually: If you're still uncertain, you can measure the bolt pattern yourself, though it requires a little precision.

How to Measure a 5-Lug Bolt Pattern

Measuring a 5-lug pattern requires a slightly different approach than a 4 or 6-lug pattern. Since the lugs aren't directly opposite each other, you can't simply measure the distance between two directly opposing lugs. Here's how to do it:

- Measure Center-to-Center: Measure the distance between the center of one lug hole to the outer edge of the lug hole *directly opposite* it (skipping one lug hole).

- Use a Conversion Chart: Because of the geometry, the measurement you take isn't directly the PCD. You'll need to use a conversion chart or formula to determine the correct 5-lug PCD based on your measurement. There are plenty of free charts available online; search for "5 lug bolt pattern measurement chart".

- Alternatively, Measure Adjacent Lugs and Use Geometry: This method is more accurate but requires trigonometric functions. Measure the center-to-center distance between any two *adjacent* lug holes. Let's call this distance 'd'. The Pitch Circle Diameter (PCD) can then be calculated as: PCD = d / sin(36°). This method requires very precise measurement.

Important: Use a precise measuring tool like a digital caliper for the most accurate results. Even a millimeter off can lead to selecting the wrong wheel.

Beyond the Bolt Pattern: Other Wheel Considerations

The bolt pattern is only one piece of the puzzle when selecting new wheels. Other critical factors include:

- Center Bore: The center bore is the diameter of the hole in the center of the wheel. It must be large enough to fit over the hub of your car. A wheel with a center bore that's too small simply won't fit. A larger center bore *can* be used with hub-centric rings (more on that below).

- Offset: The offset is the distance between the wheel's mounting surface and its centerline. It's measured in millimeters and can be positive, negative, or zero. Offset affects how the wheel sits in the wheel well, and getting it wrong can cause rubbing issues with the suspension or fenders.

- Wheel Width: The wheel width, usually measured in inches, determines the width of the tire that can be safely mounted on the wheel.

- Tire Size: Choose a tire size that's appropriate for the wheel width and the overall diameter specifications for your vehicle. Using the wrong tire size can affect speedometer accuracy and handling.

Hub-Centric vs. Lug-Centric Wheels

This is an important distinction. Hub-centric wheels are centered on the hub flange, providing a tight, vibration-free fit. The center bore of the wheel matches the diameter of the hub. Lug-centric wheels, on the other hand, are centered by the lug nuts. While lug-centric wheels *can* work, they are generally not preferred for most passenger vehicles due to the potential for vibration if not properly installed.

If you are using a wheel with a larger center bore than your hub, you *must* use hub-centric rings. These rings fill the gap between the wheel and the hub, ensuring that the wheel is properly centered. Hub-centric rings are usually made of plastic or aluminum.

Torque Specifications

Once you've installed your new wheels, it's crucial to torque the lug nuts to the correct specification. Over-torquing can damage the studs or warp the rotors, while under-torquing can lead to loose wheels. Consult your owner's manual or a reputable source for the correct torque specification for your 2007 Nissan Altima. A torque wrench is essential for this job.

Important Note: After driving a short distance (usually 50-100 miles) after installing new wheels, it's a good practice to re-torque the lug nuts to ensure they haven't loosened.

Common Mistakes and Troubleshooting

Here are some common mistakes to avoid when dealing with wheel bolt patterns:

- Misreading the Bolt Pattern: Double-check your measurements and references. A slight error can lead to the wrong wheel.

- Forcing the Wheel On: Never force a wheel onto the hub. If it doesn't fit easily, something is wrong. Don't try to "make it work" by tightening the lug nuts; you'll likely damage the studs or the wheel.

- Ignoring the Center Bore: As mentioned, the center bore is critical. Using the wrong size can lead to vibrations or, in extreme cases, wheel failure.

- Using the Wrong Lug Nuts: Different wheels may require different lug nuts. Make sure you're using the correct type (e.g., conical seat, ball seat, flat seat) for your wheels.

If you experience vibrations after installing new wheels, the first thing to check is that the lug nuts are properly torqued. If the vibration persists, check the center bore and make sure you're using hub-centric rings if necessary. Also, inspect the wheels and tires for any damage or defects.

In Conclusion

Choosing the correct wheel bolt pattern for your 2007 Nissan Altima is essential for safety and performance. By understanding the basics of bolt patterns, center bores, offset, and torque specifications, you can confidently select the right wheels for your vehicle and avoid costly mistakes. Remember to double-check your measurements, use reputable sources for information, and always prioritize safety.

If you're ever unsure about any aspect of wheel fitment, it's always best to consult with a professional mechanic or wheel specialist.