08 Nissan Altima Belt Diagram

The 2008 Nissan Altima, a popular mid-size sedan, relies on a serpentine belt to drive essential engine components. Understanding its routing, often referred to as the belt diagram, is crucial for maintenance, replacement, and troubleshooting. This article delves into the specifics of the 2008 Altima's belt system, covering various engine configurations and providing a comprehensive guide for professionals and enthusiasts alike.

Understanding the Serpentine Belt System

The serpentine belt is a single, continuous belt responsible for powering several critical accessories. These include the alternator (which charges the battery), the power steering pump (assisting in steering), the air conditioning compressor (cooling the cabin), and sometimes the water pump (circulating coolant to regulate engine temperature). A properly functioning serpentine belt is essential for reliable vehicle operation.

Unlike older vehicles that used multiple belts for each accessory, the serpentine belt simplifies the system, reducing maintenance complexity. However, its failure can lead to the simultaneous loss of multiple essential functions, making regular inspection and timely replacement paramount.

2008 Nissan Altima Engine Variants and Belt Diagrams

The 2008 Nissan Altima was available with two primary engine options: a 2.5-liter inline-4 (QR25DE) and a 3.5-liter V6 (VQ35DE). Each engine utilizes a different serpentine belt routing, dictated by the placement and configuration of the driven accessories.

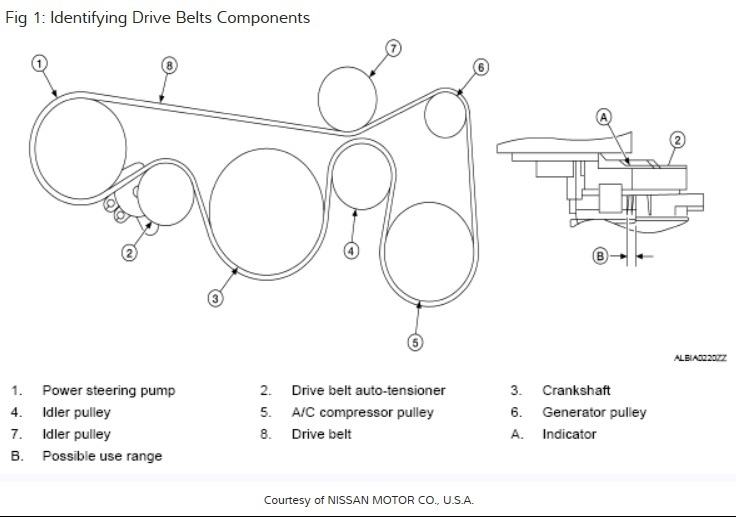

2.5-Liter QR25DE Engine Belt Diagram

The QR25DE engine features a relatively straightforward serpentine belt arrangement. The belt typically wraps around the following components:

- Crankshaft Pulley: The main driver, connected directly to the engine's crankshaft.

- Alternator Pulley: Powers the alternator.

- Power Steering Pump Pulley: Provides hydraulic assistance for steering.

- Air Conditioning Compressor Pulley: Drives the air conditioning system.

- Tensioner Pulley: Maintains proper belt tension. This is usually spring-loaded and self-adjusting.

- Idler Pulley: A smooth pulley that guides the belt around the system, optimizing its path and preventing interference.

To properly route the belt, observe the following (always consult the diagram located in your vehicle or a repair manual for exact placement):

- Start by positioning the belt around the crankshaft pulley.

- Guide the belt over the alternator pulley, ensuring it sits correctly within the grooves.

- Route the belt around the power steering pump pulley.

- Direct the belt to the air conditioning compressor pulley.

- Position the belt around the idler pulley.

- Finally, use a wrench to relieve the tension on the tensioner pulley, allowing you to slip the belt over the tensioner pulley itself. Once the belt is in place, release the tensioner, and the spring mechanism will automatically apply the correct amount of tension.

Important Note: Always ensure the belt is properly seated within the grooves of each pulley. Misalignment can cause premature wear, noise, and eventual belt failure.

3.5-Liter VQ35DE Engine Belt Diagram

The VQ35DE engine, with its more complex V6 configuration, has a slightly different serpentine belt arrangement compared to the QR25DE. The belt typically routes around these components:

- Crankshaft Pulley: The driving force behind the entire system.

- Alternator Pulley: Powers the vehicle's electrical system.

- Power Steering Pump Pulley: Assists in steering.

- Air Conditioning Compressor Pulley: Drives the air conditioning system.

- Water Pump Pulley: Circulates coolant to maintain engine temperature. This is a crucial difference from some QR25DE setups.

- Tensioner Pulley: Maintains proper belt tension. Similar to the QR25DE, it is typically spring-loaded.

- Idler Pulley: Guides the belt and prevents interference. The VQ35DE might have more than one idler pulley depending on the specific configuration.

The routing procedure is similar to the QR25DE, but the inclusion of the water pump pulley adds a step. Again, consult the specific diagram for your vehicle, but the general process is:

- Position the belt around the crankshaft pulley.

- Route the belt over the alternator pulley.

- Guide the belt around the power steering pump pulley.

- Direct the belt to the air conditioning compressor pulley.

- Route the belt around the water pump pulley.

- Position the belt around any idler pulleys.

- Using a wrench, relieve the tension on the tensioner pulley and slip the belt over the tensioner pulley itself. Release the tensioner.

Crucial Detail: Double-check the water pump pulley engagement. The water pump is critical for engine cooling, and incorrect belt routing can lead to overheating and severe engine damage.

Serpentine Belt Inspection and Maintenance

Regular inspection of the serpentine belt is essential for preventative maintenance. Look for the following signs of wear and tear:

- Cracks: Cracks running perpendicular to the belt's length indicate aging and impending failure.

- Glazing: A shiny or glossy appearance on the belt's surface suggests slippage and reduced friction.

- Fraying: Fraying edges indicate wear and potential delamination.

- Missing Chunks: Any missing pieces of the belt are a clear sign of damage and require immediate replacement.

- Noise: Squealing or chirping noises, especially during startup or under load, can indicate a loose or worn belt.

It's also crucial to inspect the pulleys for damage or misalignment. A bent or corroded pulley can cause premature belt wear. Check the tensioner pulley to ensure it moves freely and maintains proper tension.

Replacement Interval: A general recommendation is to replace the serpentine belt every 60,000 to 100,000 miles, or as specified in the vehicle's owner's manual. However, more frequent replacement may be necessary in harsh operating conditions.

Troubleshooting Serpentine Belt Issues

Several issues can arise with the serpentine belt system, leading to performance problems. Here are some common scenarios and troubleshooting tips:

- Squealing Noise: As mentioned earlier, squealing often indicates a loose or worn belt. Check the belt's tension and condition. If the belt is glazed or cracked, replace it. You might also need to check the tensioner pulley for proper operation. A worn tensioner spring can cause insufficient tension, leading to slippage and noise.

- Loss of Power Steering: If the power steering suddenly stops working, the serpentine belt may have broken or slipped off the power steering pump pulley. Inspect the belt and pulleys.

- Alternator Not Charging: A broken or slipping belt can prevent the alternator from charging the battery, leading to a dead battery and electrical problems. Check the belt's condition and tension.

- Overheating: If the belt drives the water pump (as in the VQ35DE), a broken or slipping belt can lead to overheating. Immediately stop the vehicle and inspect the belt.

Tools and Equipment: Replacing a serpentine belt typically requires basic tools, including a socket set, wrenches, and a serpentine belt tool (for releasing tension on the tensioner pulley). Safety glasses and gloves are also recommended.

Serpentine Belt Replacement Procedure

While a detailed step-by-step guide is beyond the scope of this article, here's a general overview of the serpentine belt replacement process:

- Safety First: Disconnect the negative battery terminal to prevent electrical shocks.

- Locate the Belt Diagram: Refer to the diagram in your vehicle's engine compartment or a repair manual.

- Release Tension: Use a serpentine belt tool or a wrench to relieve the tension on the tensioner pulley.

- Remove the Old Belt: Carefully remove the old belt from the pulleys.

- Inspect the Pulleys: Check the pulleys for damage, wear, or misalignment.

- Install the New Belt: Follow the belt diagram to properly route the new belt around the pulleys.

- Apply Tension: Release the tensioner pulley, allowing it to apply tension to the new belt.

- Verify Alignment: Double-check that the belt is properly seated within the grooves of each pulley.

- Reconnect Battery: Reconnect the negative battery terminal.

- Test the System: Start the engine and listen for any unusual noises. Verify that all accessories (power steering, air conditioning, alternator) are functioning correctly.

Professional Recommendation: If you are not comfortable performing this task yourself, it is best to have a qualified mechanic replace the serpentine belt.

Conclusion

Understanding the serpentine belt system in your 2008 Nissan Altima is essential for proper maintenance and troubleshooting. By familiarizing yourself with the belt diagram, inspection procedures, and replacement process, you can ensure the reliable operation of your vehicle and prevent costly repairs. Whether you are an experienced mechanic or a car enthusiast, this knowledge will empower you to keep your Altima running smoothly for years to come. Remember to always consult the vehicle's service manual for the most accurate and up-to-date information specific to your engine configuration.