1994 Nissan Pickup Oil Filter

The 1994 Nissan Pickup, a workhorse revered for its dependability, relies on a seemingly simple component for its engine's longevity: the oil filter. Understanding the intricacies of the oil filter specified for this vehicle is crucial for automotive professionals ensuring optimal performance and reliability.

Technical Specifications and Engineering Choices

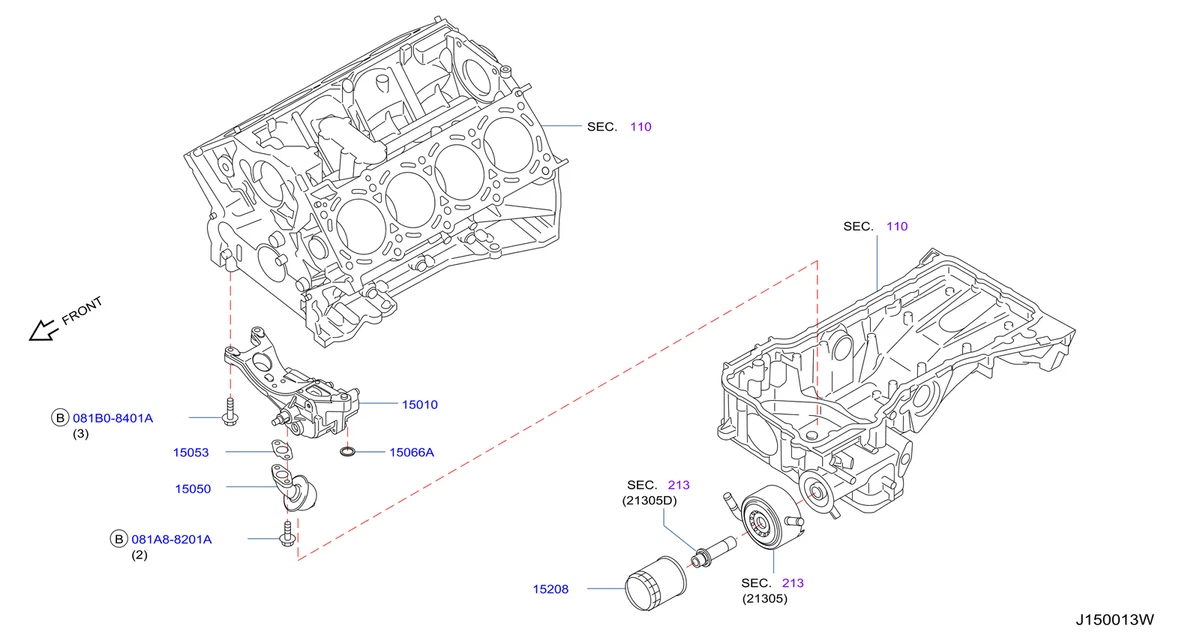

The specified oil filter for the 1994 Nissan Pickup, typically equipped with either the KA24E or VG30E engine, is generally a spin-on type filter adhering to industry standards. Common part numbers include, but are not limited to, Nissan OEM filters (often with a specific Nissan part number dependent on the engine and region) and aftermarket equivalents like those from Purolator (e.g., Purolator L14610), Fram (e.g., Fram PH3614), and Mobil 1 (e.g., M1-110). These filters generally have a thread size of 3/4-16 UNF and a gasket outer diameter around 2.7 inches, designed to mate securely with the engine's filter mount.

Engineering choices behind these filters involve several key aspects:

- Filtration Media: Most filters utilize cellulose-based media, sometimes blended with synthetic fibers. The pore size of the media is engineered to trap particles typically between 20-25 microns, effectively removing contaminants like dirt, metal shavings, and soot while allowing vital oil additives to pass through. Premium filters often employ fully synthetic media offering superior filtration efficiency and dirt-holding capacity.

- Bypass Valve: A critical safety feature is the bypass valve. This valve opens when the filter becomes excessively clogged or when the oil is cold and viscous, allowing oil to flow directly to the engine, bypassing the filter. This prevents oil starvation, which can cause catastrophic engine damage. The bypass valve opening pressure is typically set around 8-11 psi.

- Anti-Drainback Valve: Located within the filter, the anti-drainback valve prevents oil from draining back into the oil pan when the engine is off. This ensures that oil is readily available upon startup, minimizing wear and tear during the crucial initial seconds of operation.

- Canister Construction: The filter canister is typically constructed from stamped steel, designed to withstand high oil pressure and temperature. Seam welds are critical for preventing leaks.

Real-World Performance and Comparison with Alternatives

In real-world use, the specified oil filters for the 1994 Nissan Pickup generally perform adequately when changed according to the manufacturer's recommended service intervals (typically every 3,000-5,000 miles). However, performance can vary significantly depending on the brand and quality of the filter.

Comparison with Alternatives:

Standard Filters (e.g., Fram Extra Guard, Purolator Classic)

Pros: Inexpensive, readily available.

Cons: Lower filtration efficiency, limited dirt-holding capacity, may use less durable materials.

Premium Filters (e.g., Mobil 1, Royal Purple, Amsoil)

Pros: Superior filtration efficiency (often using synthetic media), higher dirt-holding capacity, more robust construction, may offer extended service intervals (though sticking to manufacturer recommendations is generally advised for older vehicles).

Cons: Higher cost.

Extended Performance Filters (e.g., Bosch Distance Plus, Fram Ultra Synthetic)

Pros: Designed for extended oil change intervals (check oil manufacturer specifications), excellent filtration and dirt-holding capacity, often made with synthetic media.

Cons: Higher cost, potentially unnecessary for older engines not originally designed for synthetic oils or extended intervals. Careful consideration of oil type is crucial when using these filters.

Choosing the right filter depends on the owner's budget and priorities. For a daily driver experiencing normal driving conditions, a standard filter changed regularly is often sufficient. However, for vehicles subjected to harsh driving conditions (e.g., towing, off-roading, frequent short trips), a premium filter can provide added protection and peace of mind. Using an extended performance filter on a well-maintained engine using synthetic oil could be an option, but careful monitoring of oil condition is recommended. It's critical to avoid using lower-quality filters that could compromise engine health.

Reliability Aspects and Maintenance Tips

The reliability of the oil filter directly impacts the engine's longevity. A poorly constructed filter can leak, collapse internally, or fail to adequately filter the oil, leading to premature engine wear and potential failure.

Maintenance Tips:

- Regular Oil Changes: Adhere to the manufacturer's recommended oil change intervals. Even with a high-quality filter, the oil itself degrades over time and becomes contaminated.

- Proper Installation: Ensure the filter gasket is lightly lubricated with fresh oil before installation. Hand-tighten the filter until the gasket makes contact with the engine, then tighten an additional ¾ to 1 full turn. Over-tightening can damage the gasket and cause leaks.

- Inspect for Leaks: After starting the engine, immediately inspect the filter for leaks.

- Use the Correct Filter: Always use the oil filter specified for the 1994 Nissan Pickup, considering the engine type (KA24E or VG30E). Using an incorrect filter can compromise its sealing and filtration performance.

- Consider Oil Analysis: For high-mileage vehicles or those subjected to demanding use, consider periodic oil analysis to monitor engine wear and oil condition. This can provide valuable insights into the effectiveness of the filtration system.

- Pre-fill the Filter: Pre-filling the filter with fresh oil before installation helps reduce the period of oil starvation upon start-up. This is especially beneficial after the engine has been sitting for an extended period.

Future Trends and the Automotive Industry

The automotive industry is rapidly evolving, with electric vehicles (EVs) becoming increasingly prevalent. While EVs don't require oil filters in the traditional sense, filtration remains crucial in other areas, such as cooling systems and hydraulic systems (if equipped). As internal combustion engines (ICEs) continue to be used in hybrid vehicles, the need for advanced oil filtration technologies will persist. Expect to see further advancements in filter media, with increased use of synthetic materials and nano-filtration technologies to improve efficiency and extend service intervals.

Furthermore, the focus on sustainability is driving the development of more environmentally friendly filters that are easier to recycle or dispose of responsibly. Manufacturers are exploring alternative materials and designs to minimize the environmental impact of oil filter production and disposal.

Data analytics and predictive maintenance are also playing a growing role. Sensors can monitor oil condition and filter performance in real-time, allowing for proactive maintenance and preventing potential engine problems. This integration of technology will further optimize engine lubrication and extend the lifespan of both the engine and the oil filter.

The 1994 Nissan Pickup, while representing an older generation of vehicles, serves as a reminder of the fundamental importance of proper maintenance and the crucial role of seemingly simple components like the oil filter in ensuring vehicle reliability. Understanding the engineering principles behind these components and staying abreast of future trends is essential for automotive professionals to effectively service and maintain vehicles, both old and new.