2004 Nissan Maxima Crank Sensor Location

Alright, Maxima maniacs! Let's dive into something that can throw a wrench into your VQ-powered fun: the dreaded crank position sensor. Specifically, we're tackling the 2004 Nissan Maxima, a year that represents a sweet spot for many enthusiasts. This model year offered a blend of performance, reliability, and that classic Nissan charm. But even the mighty Maxima isn't immune to sensor gremlins. Today, we're zeroing in on the location of the crank position sensor, a critical component for keeping your engine purring (or roaring, depending on your mods).

Understanding the Crank Position Sensor

Before we get our hands dirty (figuratively, for now), let's quickly recap what a crank position sensor does. Essentially, it tells the engine control unit (ECU) the exact position and rotational speed of the crankshaft. This information is vital for proper ignition timing and fuel injection. A faulty sensor can lead to a whole host of problems, from rough idling and poor performance to a complete no-start situation. And trust us, nobody wants that.

Now, the good news is that the 2004 Maxima, regardless of trim level (SE, SL), uses the same 3.5-liter VQ35DE engine. This means, thankfully, that the crank sensor location is consistent across the board. No need to worry about different variations depending on whether you opted for the leather seats or the sunroof.

The Location: Where to Find It

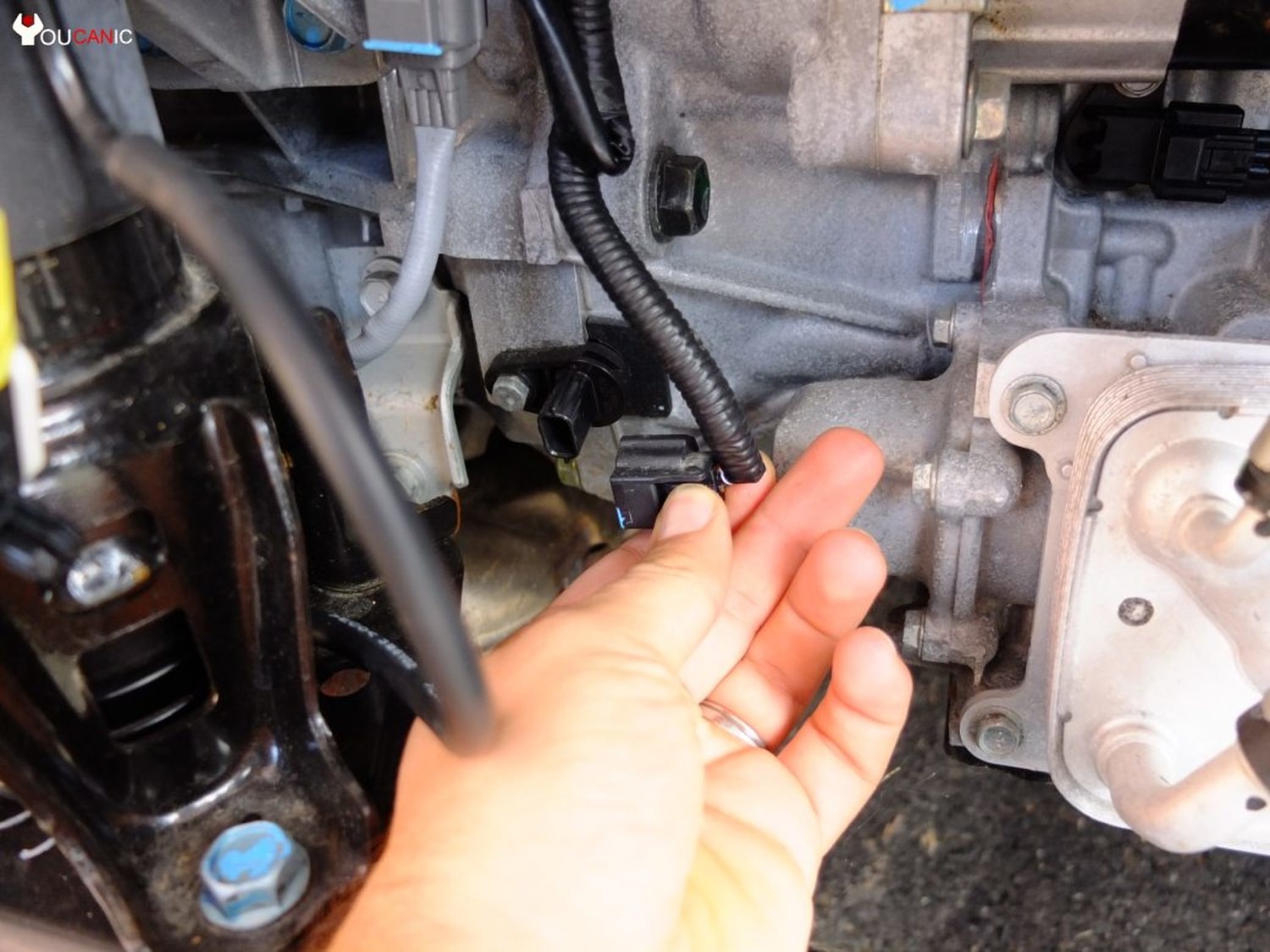

Okay, let's get down to brass tacks. The crank position sensor on the 2004 Nissan Maxima VQ35DE is located on the rear of the engine block, near the transmission bellhousing. It's positioned on the driver's side, slightly tucked away, but definitely accessible with the right tools and a bit of patience. Because it's mounted to the engine block, its purpose is reading the crankshaft’s speed and position. This is unlike the camshaft position sensor which is located on the cylinder head and reads the camshaft’s speed and position.

Here's a breakdown to help you visualize it:

- Stand facing the engine bay.

- Locate the transmission.

- Follow the transmission bellhousing upwards towards the engine block.

- The crank sensor will be mounted on the rear of the block, close to where it meets the transmission.

While the location is consistent, accessibility can vary depending on what other components are installed around it. Aftermarket headers, for example, might make the job a bit more challenging.

Replacing the Crank Position Sensor: A Quick Guide

While this isn't a full DIY tutorial, here's a quick overview of the replacement process:

- Disconnect the battery. Safety first!

- Locate the crank position sensor.

- Unplug the electrical connector. It might have a retaining clip.

- Remove the mounting bolt (usually a 10mm or 12mm).

- Carefully remove the old sensor.

- Install the new sensor, ensuring it's properly seated.

- Tighten the mounting bolt to the correct torque specification (consult your service manual).

- Plug in the electrical connector.

- Reconnect the battery.

- Start the engine and verify proper operation. It might take a few start attempts for the ECU to relearn.

Important Note: Always use a quality replacement sensor from a reputable brand. Cheap aftermarket sensors can be unreliable and cause further problems.

Pros and Cons of the VQ35DE Crank Sensor Location

Let's weigh the advantages and disadvantages of the crank sensor's placement on the VQ35DE in the 2004 Maxima:

Pros:

- Consistent Location: As mentioned earlier, the location is the same across all 2004 Maxima models with the VQ35DE engine, simplifying diagnosis and replacement.

- Relatively Accessible: Compared to some engines, the crank sensor is reasonably accessible, especially if your Maxima is relatively stock.

Cons:

- Tight Space: The rear engine location means working in a somewhat cramped space.

- Heat Exposure: Being close to the exhaust and transmission exposes the sensor to significant heat, which can contribute to premature failure.

- Potential for Oil Contamination: Leaks from the rear main seal or valve cover can potentially contaminate the sensor, affecting its performance.

Real-World Driving Impressions and Common Issues

The 2004 Maxima is known for its spirited performance, thanks in large part to the VQ35DE engine. However, a failing crank position sensor can quickly turn that exhilarating driving experience into a frustrating one. Here are some common symptoms to watch out for:

- Rough Idling: The engine might idle unevenly or even stall.

- Hesitation or Stalling: You might experience hesitation during acceleration or the engine might stall unexpectedly.

- Check Engine Light (CEL): The CEL is a common indicator, often accompanied by a code related to the crank position sensor (e.g., P0335).

- Reduced Fuel Economy: The ECU might compensate for the faulty sensor by adjusting fuel delivery, leading to decreased fuel efficiency.

- No-Start Condition: In severe cases, a completely failed crank sensor can prevent the engine from starting altogether.

Many owners report that the crank sensor issues often surface around the 100,000-mile mark, so it's a good idea to be proactive and consider replacing it as part of your preventative maintenance schedule.

Spec Table: 2004 Nissan Maxima VQ35DE Crank Sensor

| Component | Specification |

|---|---|

| Type | Hall Effect Sensor |

| Location | Rear of Engine Block, near Transmission Bellhousing (Driver's Side) |

| Connector Type | 3-Pin Connector |

| Typical Resistance | Varies depending on temperature and brand (Consult service manual for specific values) |

| Bolt Size | Usually 10mm or 12mm |

Final Thoughts

The 2004 Nissan Maxima is a fantastic car, offering a rewarding driving experience and a healthy dose of reliability. Understanding the location and function of key components like the crank position sensor is crucial for maintaining your Maxima in top condition. While the location is consistent across models, remember that accessibility can vary depending on modifications. Always use quality replacement parts and consult a service manual for proper torque specifications.

Bonus Tip: When replacing the crank sensor, consider replacing the camshaft position sensors as well. They often fail around the same time, and replacing them together can save you time and effort in the long run.

"I've heard some people say that using a dab of dielectric grease on the connector can help prevent corrosion and extend the sensor's life. What are your thoughts?"

Now, here's where the fun begins. Is dielectric grease a must-have for crank sensor replacement, or is it just overkill? Let the debate commence in the comments below!