2004 Nissan Titan Fuel Pump Relay Location

The 2004 Nissan Titan, a full-size pickup truck marking Nissan's entry into a highly competitive market, employed a fairly standard fuel injection system reliant on a robust fuel pump. A crucial component of this system is the fuel pump relay, responsible for providing power to the fuel pump. Understanding its location, function, and potential issues is vital for automotive professionals working on these vehicles.

Locating the Fuel Pump Relay

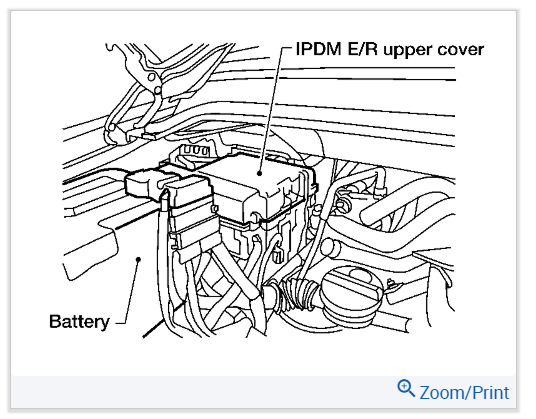

The fuel pump relay in the 2004 Nissan Titan is typically found within the Intelligent Power Distribution Module (IPDM), often referred to as the IPDM/ER (Engine Room). This module is located in the engine compartment, usually near the battery. Locating the exact relay within the IPDM can sometimes be tricky due to variations in IPDM layouts across different production runs. Always consult the vehicle's specific wiring diagram or a reliable repair manual for precise identification. Labeling on the IPDM cover, while present, can sometimes be ambiguous or faded over time. A multimeter can also be used to test each relay to confirm which is the correct one, following the wiring diagrams.

Technical Specifications and Engineering Choices

The fuel pump relay itself is an electromechanical device. It consists of a coil, contacts, and a spring mechanism. When the ignition is turned on, the Engine Control Module (ECM) sends a signal to the relay coil. This energizes the coil, creating a magnetic field that pulls the contacts together, completing the circuit and allowing power to flow to the fuel pump. Typical specifications for the relay include a 12V DC operating voltage and a current rating sufficient to handle the fuel pump's power draw, generally around 20-30 amps. Nissan, like other manufacturers, opted for this relay system for its simplicity, cost-effectiveness, and relatively high reliability compared to earlier mechanical fuel pump systems.

The engineering choice of using a relay stems from the desire to protect the ECM. The ECM is a sensitive electronic device, and directly switching the high current required by the fuel pump could potentially damage it. The relay acts as an intermediary, using a low-current signal from the ECM to control a high-current circuit. This isolates the ECM from the fuel pump's electrical load, enhancing the overall system's reliability and longevity.

Real-World Performance and Common Issues

In the real world, the fuel pump relay in the 2004 Titan, like any electrical component, is susceptible to failure. Common issues include:

- Relay Contact Corrosion: Over time, moisture and contaminants can corrode the relay contacts, leading to increased resistance and intermittent fuel pump operation. This often manifests as hard starting or stalling.

- Coil Failure: The relay coil can fail due to overheating or electrical surges, preventing the relay from energizing and cutting off power to the fuel pump.

- IPDM Issues: Problems within the IPDM itself, such as circuit board damage or faulty connections, can also prevent the relay from functioning correctly. This is less common, but a possibility, especially in older vehicles exposed to harsh environments.

- Wiring Problems: Damaged or corroded wiring between the ECM, relay, and fuel pump can also mimic relay failure symptoms.

When diagnosing fuel pump issues, it's crucial to check the relay first. A simple test involves swapping the fuel pump relay with an identical relay (e.g., the horn relay). If the fuel pump then operates correctly, the original relay is likely the culprit. However, a thorough diagnosis should include checking for proper voltage at the relay terminals and verifying the continuity of the wiring harness.

Comparison with Alternatives

While relays remain a common choice, Solid State Relays (SSRs) offer a potential alternative. SSRs use semiconductor technology to switch circuits, offering several advantages:

Pros of SSRs:

- Longer lifespan due to the absence of moving parts.

- Faster switching speeds.

- Quieter operation.

- Greater resistance to vibration and shock.

Cons of SSRs:

- Higher cost.

- Can generate heat, requiring heat sinking in high-current applications.

- May be more susceptible to damage from voltage spikes.

For the 2004 Titan, the cost-effectiveness and proven reliability of electromechanical relays made them the preferred choice. However, as technology advances and costs decrease, SSRs may become more prevalent in future automotive applications.

Reliability Aspects and Maintenance Tips

The fuel pump relay in the 2004 Titan is generally considered reliable, but preventative maintenance can help extend its lifespan. Consider the following:

- Regular Inspection: Visually inspect the IPDM and relay for signs of corrosion or damage.

- Relay Replacement: As a preventative measure, replace the fuel pump relay every 5-7 years, especially in vehicles operating in harsh climates.

- IPDM Protection: Ensure the IPDM cover is properly sealed to prevent moisture and contaminants from entering.

- Battery Maintenance: A healthy battery helps prevent voltage fluctuations that can stress electrical components, including the relay.

Additionally, when replacing the fuel pump relay, always use a high-quality replacement part from a reputable manufacturer. Using a cheap, generic relay can lead to premature failure and potential damage to the fuel pump or ECM.

Future Trends

The automotive industry is rapidly evolving, with a growing emphasis on electric vehicles (EVs) and advanced driver-assistance systems (ADAS). In EVs, the traditional fuel pump relay is obviously absent, replaced by components managing the high-voltage battery and electric motor. Even in internal combustion engine (ICE) vehicles, there's a trend towards more sophisticated power distribution systems, potentially incorporating solid-state devices and integrated control modules. These systems aim to improve efficiency, reduce weight, and enhance diagnostic capabilities.

Furthermore, the increasing use of data analytics and predictive maintenance will enable manufacturers to identify potential component failures before they occur. This will allow for proactive maintenance and reduce the risk of breakdowns, improving overall vehicle reliability and customer satisfaction.

Conclusion

Understanding the location, function, and potential issues of the fuel pump relay in the 2004 Nissan Titan is crucial for automotive professionals. While the relay system is relatively simple and reliable, preventative maintenance and accurate diagnostics are essential for ensuring optimal performance. As the automotive industry continues to evolve, new technologies and power distribution strategies will emerge, offering improved efficiency and reliability. Staying abreast of these trends will be vital for automotive professionals to effectively service and maintain vehicles in the future.