2005 Nissan Altima Drive Belt

The serpentine belt, or drive belt as it's often called, is a seemingly simple component that plays a critical role in the operation of your 2005 Nissan Altima. It's responsible for transmitting power from the engine's crankshaft to various accessories, ensuring these components function correctly. Understanding its operation, potential issues, and replacement procedure is valuable knowledge for any car enthusiast or aspiring mechanic.

The Role of the Drive Belt: A Symphony of Power Transfer

Imagine a complex mechanical orchestra. The engine crankshaft is the conductor, providing the driving force. The serpentine belt acts as the messenger, delivering the conductor's instructions (rotational energy) to the various instruments (accessories). Specifically, on a 2005 Nissan Altima (depending on the engine – either the 2.5L QR25DE inline-4 or the 3.5L VQ35DE V6), the serpentine belt typically drives the following:

- Alternator: Powers the electrical system and charges the battery. A failing belt here leads to a discharged battery and electrical problems.

- Power Steering Pump: Provides hydraulic assistance for steering. A slipping belt results in stiff, difficult steering.

- Air Conditioning Compressor: Compresses the refrigerant that cools the cabin. A broken belt will result in no air conditioning.

- Water Pump (on some engines): Circulates coolant through the engine to prevent overheating. This is a critical function, as a failed water pump will lead to rapid engine damage due to overheating. On some Altima models, the water pump is driven by the timing chain, not the serpentine belt. Confirm your engine configuration before proceeding with any diagnostic or repair work related to the water pump and drive belt.

The belt accomplishes this power transfer through friction. The belt is wrapped tightly around various pulleys connected to these accessories and the crankshaft pulley. As the crankshaft rotates, it pulls on the belt, which in turn rotates the accessory pulleys. The tension in the belt is crucial for proper operation. Too little tension, and the belt will slip, resulting in reduced performance or complete failure of the accessories. Too much tension can damage the accessories' bearings and shorten the belt's lifespan. This tension is maintained by a spring loaded tensioner pulley.

Material Science and Construction

Serpentine belts are typically made from a durable composite material, often a blend of synthetic rubbers like EPDM (ethylene propylene diene monomer) reinforced with fabric cords. The EPDM provides resistance to heat, oil, and ozone, extending the belt's service life. The fabric cords, usually polyester or aramid fibers, provide the tensile strength necessary to withstand the high loads and stresses placed on the belt. The belt's grooved design (often V-ribbed) increases the surface area in contact with the pulleys, enhancing grip and reducing slippage. The number of ribs and their dimensions are precisely engineered for specific engine and accessory configurations. Using the wrong belt can lead to premature wear, slippage, and damage to the pulleys.

Over time, the belt material degrades due to heat, friction, and exposure to environmental factors. This degradation manifests as:

- Cracking: Small cracks appear on the ribs of the belt.

- Glazing: The belt surface becomes smooth and shiny, reducing its grip.

- Fraying: The edges of the belt become frayed and worn.

- Chunking: Pieces of the belt material break off.

Any of these signs indicate that the belt needs to be replaced. Neglecting these warning signs can lead to catastrophic belt failure, leaving you stranded and potentially damaging other components.

Diagnosing Drive Belt Issues: Sound and Sight

Diagnosing drive belt problems often involves a combination of visual inspection and listening for unusual noises. Common symptoms of a worn or damaged drive belt include:

- Squealing or chirping noise: This is often heard when the engine is first started, or when accessories like the air conditioning or power steering are heavily loaded. The noise is caused by the belt slipping on the pulleys.

- Loss of power steering: A slipping belt may not provide sufficient power to the power steering pump, resulting in stiff or difficult steering.

- Dim headlights or charging problems: A slipping belt may not properly drive the alternator, leading to insufficient charging of the battery and dim headlights.

- Overheating: If the belt drives the water pump (check your specific engine configuration!), a broken or slipping belt can cause the engine to overheat.

- Visible damage to the belt: Cracks, glazing, fraying, or chunking are clear signs that the belt needs to be replaced.

To diagnose a suspected drive belt problem, start by visually inspecting the belt. Look for any signs of damage as described above. Also, check the alignment of the pulleys. Misaligned pulleys can cause the belt to wear unevenly and prematurely. Next, listen carefully for any unusual noises coming from the belt area. A mechanic's stethoscope can be helpful for pinpointing the source of the noise.

A simple test to check belt tension involves pressing down on the belt between two pulleys. There should be a slight amount of deflection, but not excessive slack. Consult the vehicle's service manual for the recommended belt tension specifications. Also inspect the tensioner itself. A failing tensioner can cause the belt to become loose and slip, even if the belt itself is in good condition.

Replacement Procedure: A Step-by-Step Guide (General - Consult Your Vehicle's Repair Manual)

Disclaimer: This is a general overview. Always consult your 2005 Nissan Altima's repair manual for specific instructions and safety precautions.

Tools Required:

- Socket set with extensions

- Wrench set

- Serpentine belt tool (highly recommended, especially for tight spaces)

- Gloves

- Safety glasses

- Torque wrench

Steps:

- Safety First: Disconnect the negative battery terminal to prevent electrical shock.

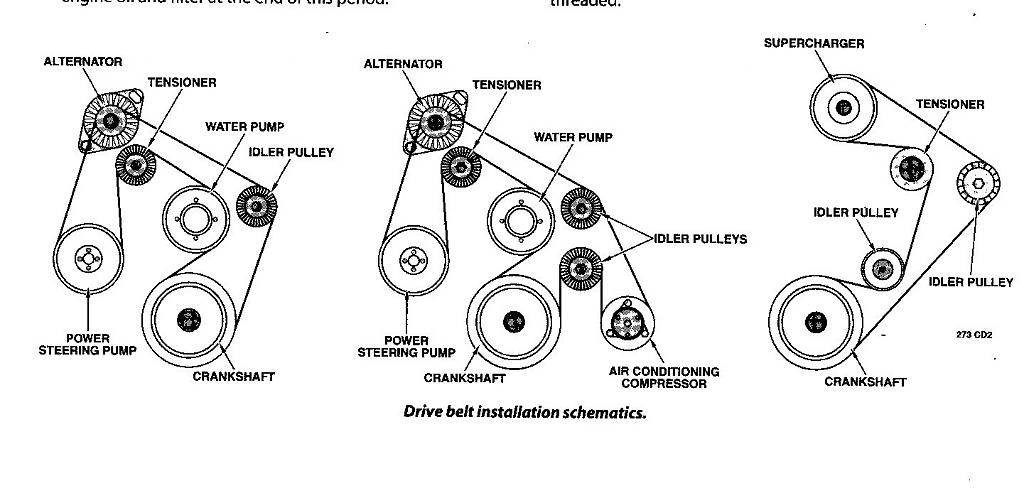

- Locate the Belt Routing Diagram: This diagram shows how the belt is routed around the various pulleys. It's usually located under the hood or in the repair manual. Take a picture of the existing belt routing before removing it as a backup.

- Release the Belt Tension: Use the serpentine belt tool or a wrench to rotate the tensioner pulley, relieving the tension on the belt. Some tensioners have a square hole for a ratchet, while others require a wrench to be applied to the tensioner pulley bolt.

- Remove the Old Belt: While holding the tensioner in the released position, carefully slip the old belt off the pulleys.

- Inspect the Pulleys: Check the pulleys for any signs of damage, such as cracks, chips, or excessive wear. Spin each pulley by hand to check for smooth rotation and bearing noise. Replace any damaged pulleys.

- Install the New Belt: Following the belt routing diagram, carefully route the new belt around the pulleys. Make sure the belt is properly seated in the grooves of each pulley.

- Release the Tensioner: Slowly release the tensioner, allowing it to apply tension to the new belt. Double-check that the belt is still properly seated on all the pulleys.

- Verify Belt Alignment: Ensure that the belt is running straight and true on all the pulleys.

- Reconnect the Battery: Reconnect the negative battery terminal.

- Start the Engine: Start the engine and listen carefully for any unusual noises. Observe the belt to make sure it's running smoothly and not slipping.

- Check Belt Tension: After a few minutes of running, check the belt tension again. Adjust as necessary.

Important Note: Over-tightening the belt can damage the accessory bearings. Refer to your vehicle's repair manual for the correct belt tension specifications and torque settings.

Choosing the Right Replacement Belt

Selecting the correct replacement serpentine belt is crucial for ensuring proper performance and longevity. Always use a belt that is specifically designed for your 2005 Nissan Altima's engine and accessory configuration. The belt's length, width, and rib profile must match the original equipment specifications. Using the wrong belt can lead to slippage, premature wear, and damage to the pulleys.

Purchase belts from reputable manufacturers known for their quality and durability. Avoid cheap, generic belts, as they may not meet the required specifications and may fail prematurely. Popular brands include Gates, Dayco, and Goodyear (Continental). When purchasing a belt, check the part number to ensure it's the correct one for your vehicle. Many online retailers and auto parts stores have vehicle look-up tools that can help you find the right belt.

Preventative Maintenance: Extending Belt Life

While serpentine belts are designed to be durable, proper maintenance can significantly extend their lifespan. Here are some tips for keeping your drive belt in good condition:

- Regular Visual Inspections: Inspect the belt regularly for any signs of damage, such as cracks, glazing, fraying, or chunking.

- Check Belt Tension: Periodically check the belt tension and adjust as necessary.

- Address Oil Leaks: Oil and other fluids can damage the belt. Fix any oil leaks promptly.

- Replace Pulleys and Tensioner When Necessary: If the pulleys or tensioner are damaged or worn, replace them along with the belt.

By following these simple maintenance tips, you can help ensure that your 2005 Nissan Altima's serpentine belt provides reliable performance for many miles to come.

The Silent Workhorse

The drive belt is a vital, yet often overlooked, component in your 2005 Nissan Altima. Understanding its function, construction, and potential problems is key to maintaining your vehicle's reliability and preventing costly repairs. By performing regular inspections and following the recommended maintenance procedures, you can ensure that your Altima's "silent workhorse" continues to deliver reliable performance for years to come.