2005 Nissan Maxima Cam Sensor

The 2005 Nissan Maxima, a mid-size sedan known for its sporty handling and potent V6 engine, relies heavily on the precise functioning of its camshaft position sensors (CMP). These sensors play a crucial role in engine timing and overall performance. This article delves into the technical specifications, engineering choices, real-world performance, and maintenance considerations surrounding the cam sensors in this specific model year.

Technical Specifications and Engineering Choices

The 2005 Maxima utilizes two CMP sensors, one for each cylinder bank (Bank 1 and Bank 2). These sensors are typically of the Hall-effect type. This technology relies on the Hall effect, where a voltage difference (the Hall voltage) is produced across an electrical conductor, transverse to an electric current in the conductor and a magnetic field perpendicular to the current.

Specific technical details for the 2005 Maxima's CMP sensors include:

- Type: Hall-effect

- Operating Voltage: Typically 5V DC

- Output Signal: Digital square wave (on/off signal)

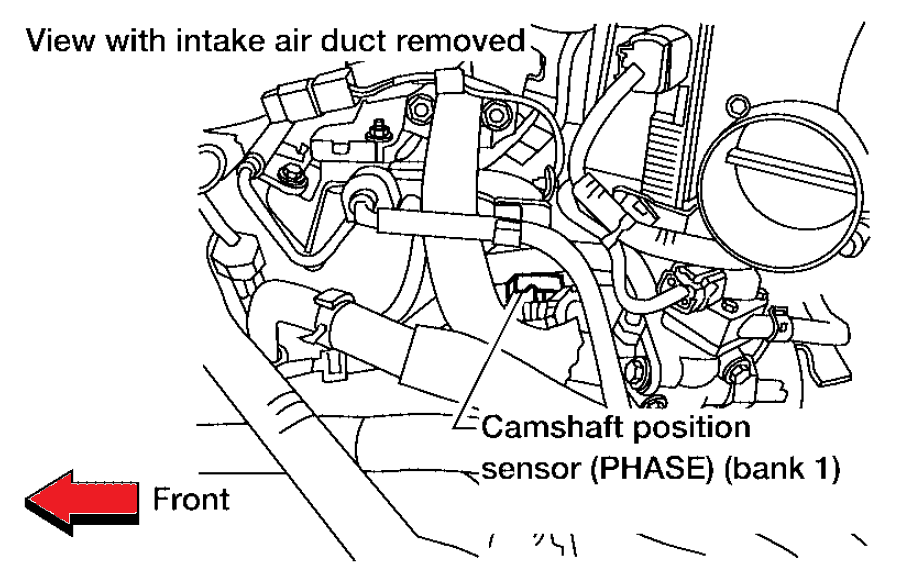

- Location: Mounted near the camshaft sprockets, typically under the valve covers.

- Connector Type: 3-pin connector (Power, Ground, Signal)

- OEM Part Numbers: Varies depending on the exact engine configuration, but generally similar to other Nissan VQ series engines of the era. Checking a parts catalog with the VIN is essential for accurate identification.

The engineering choice of using Hall-effect sensors provides several advantages. They are relatively robust, resistant to contamination, and offer a clean digital signal that's easily interpreted by the engine control unit (ECU). The placement of the sensors near the camshaft sprockets allows for accurate detection of the camshaft's position. The ECU uses this information, along with the crankshaft position sensor (CKP) data, to determine the precise timing of fuel injection and ignition events.

The digital square wave output is crucial. As the camshaft rotates, teeth or slots on the camshaft sprocket interrupt the magnetic field sensed by the Hall-effect sensor. This interruption causes the sensor to switch between "on" and "off" states, generating the square wave signal. The ECU then counts the pulses in this signal and calculates the camshaft's position and speed.

Real-World Performance and Diagnostics

A malfunctioning cam sensor in a 2005 Maxima can manifest in various ways, significantly impacting performance and drivability. Common symptoms include:

- Engine misfires: Incorrect timing leads to incomplete combustion.

- Rough idling: Unstable engine operation at idle.

- Loss of power: Reduced engine output, especially during acceleration.

- Difficulty starting: The engine may crank for an extended period before starting, or fail to start altogether.

- Check Engine Light (CEL): Diagnostic Trouble Codes (DTCs) related to cam sensor failure are typically stored in the ECU's memory. Common DTCs include P0340 (Camshaft Position Sensor A Circuit Malfunction) and P0345 (Camshaft Position Sensor A Circuit Bank 2).

- Fuel economy decrease: Inefficient combustion leads to increased fuel consumption.

Diagnosing a faulty cam sensor requires a systematic approach. A scan tool is essential to retrieve any stored DTCs. However, simply reading the codes isn't enough; further investigation is necessary. This includes:

- Visual inspection: Checking the sensor and its wiring harness for any signs of damage, corrosion, or loose connections.

- Voltage testing: Verifying that the sensor is receiving the correct supply voltage (typically 5V) and ground.

- Signal testing: Using an oscilloscope or multimeter to monitor the sensor's output signal while the engine is running. A healthy sensor will produce a clear and consistent square wave signal.

- Resistance testing: Comparing the sensor's resistance to the manufacturer's specifications.

- Wiring harness testing: Ensuring continuity and absence of shorts in the wiring between the sensor and the ECU.

It's important to differentiate cam sensor issues from other potential causes of similar symptoms. For example, a faulty crankshaft position sensor (CKP) can produce similar symptoms. Vacuum leaks, ignition system problems, and fuel delivery issues can also mimic cam sensor problems. Therefore, a thorough diagnostic process is crucial.

Comparison with Alternatives

While Hall-effect sensors are the dominant technology for CMP sensors, other alternatives exist, although less commonly used in automotive applications for this specific application:

- Variable Reluctance Sensors (VRS): These sensors generate an AC voltage signal based on the changing magnetic field as a toothed wheel rotates. VRS sensors are simpler and don't require an external power supply, but they are more susceptible to noise and their signal strength varies with engine speed. They are less precise than Hall-effect sensors at low speeds.

- Magnetoresistive Sensors: These sensors use the magnetoresistive effect, where a material's resistance changes in the presence of a magnetic field. Magnetoresistive sensors offer high sensitivity and accuracy, but they can be more expensive than Hall-effect sensors.

Pros and Cons of Hall-effect sensors (as used in the 2005 Maxima):

Pros:

- Robust and reliable

- Resistant to contamination

- Clean digital output signal

- Accurate at low speeds

- Cost-effective

Cons:

- Requires an external power supply

The choice of Hall-effect sensors for the 2005 Maxima reflects a balance between performance, reliability, and cost-effectiveness. Their robustness and accurate signal make them well-suited for the demanding environment under the hood.

Reliability Aspects and Maintenance Tips

Cam sensors, while generally reliable, are not immune to failure. Common causes of failure include:

- Heat: Prolonged exposure to high engine temperatures can degrade the sensor's internal components.

- Vibration: Engine vibrations can cause stress on the sensor and its wiring harness.

- Contamination: Oil leaks or coolant leaks can damage the sensor.

- Electrical issues: Short circuits or open circuits in the wiring harness can cause the sensor to fail.

Maintenance tips to prolong the life of cam sensors include:

- Regular oil changes: Using high-quality oil and changing it at the recommended intervals helps to keep the engine clean and reduce heat buildup.

- Inspecting for leaks: Regularly checking for oil or coolant leaks around the sensors. Addressing leaks promptly prevents contamination.

- Checking wiring: Periodically inspecting the sensor's wiring harness for any signs of damage or corrosion.

- Using OEM or reputable aftermarket parts: When replacing a cam sensor, using a high-quality replacement part ensures proper fit and function.

When replacing a cam sensor, it's crucial to follow the manufacturer's instructions carefully. This typically involves disconnecting the battery, removing the sensor, installing the new sensor, and reconnecting the battery. In some cases, relearn procedures may be necessary after replacement.

Future Trends

The automotive industry is rapidly evolving, with advancements in engine technology and sensor technology. Future trends related to cam sensors include:

- More sophisticated sensors: Sensors with integrated diagnostics and self-calibration capabilities.

- Wireless sensors: Eliminating the need for wiring harnesses, reducing weight and complexity.

- Advanced materials: Using more durable and heat-resistant materials to extend sensor lifespan.

- Integration with other systems: Cam sensor data being used by other vehicle systems, such as adaptive cruise control and lane departure warning.

As engines become more complex and fuel efficiency demands increase, the role of cam sensors will become even more critical. Precise engine timing will be essential for optimizing performance and reducing emissions.

Conclusion

The 2005 Nissan Maxima's cam sensors are integral to its engine's performance and reliability. Understanding their technical specifications, potential failure modes, and maintenance requirements is crucial for automotive professionals. As the automotive industry continues to innovate, sensors will play an increasingly important role in vehicle operation. The future of automotive technology hinges on the ability to develop and integrate advanced sensor systems that are more reliable, accurate, and efficient. This necessitates a continuous learning approach for automotive professionals to stay abreast of the latest advancements and diagnostic techniques, ensuring they can effectively service and maintain the vehicles of tomorrow. The shift towards electric vehicles and hybrid powertrains may reduce the direct dependence on traditional camshaft-based timing mechanisms, but the principles of accurate rotational position sensing will undoubtedly continue to be vital in various motor control and drivetrain applications.