2006 Nissan Maxima Cam Sensor

The 2006 Nissan Maxima, known for its blend of sporty performance and near-luxury features, relies on a sophisticated engine management system to deliver that experience. A critical component of this system is the camshaft position sensor, often referred to as the cam sensor. While seemingly small and simple, the cam sensor plays a vital role in engine operation. Let's dive into what this sensor does, why it's important, how to identify potential problems, and what you can do about it.

What is a Cam Sensor and What Does it Do?

Think of your engine as a precisely choreographed dance of fuel, air, and spark. The cam sensor is one of the key timekeepers in this dance. Its primary job is to tell the engine control unit (ECU), also known as the engine computer, the exact position of the camshaft. The camshaft, in turn, controls the opening and closing of the intake and exhaust valves. This information is crucial for the ECU to accurately determine:

- Fuel Injection Timing: Knowing the camshaft position allows the ECU to inject fuel at the optimal moment in each cylinder, maximizing efficiency and power. Think of it like a chef knowing precisely when to add the seasoning for the best flavor.

- Ignition Timing: Similarly, the ECU uses the cam sensor data to fire the spark plugs at the precise instant required for combustion. This ensures a complete and powerful burn of the fuel-air mixture.

- Crankshaft Position Correlation: The cam sensor works in tandem with the crankshaft position sensor (crank sensor). The crank sensor monitors the position of the crankshaft (which is connected to the pistons). The ECU compares the signals from both sensors to ensure everything is in sync. This comparison is vital for detecting timing issues and potential mechanical problems. Imagine a synchronized swimming team; the ECU needs to know that the cam sensor and crank sensor are performing their routines in perfect unison.

Without a properly functioning cam sensor, the ECU is essentially blind to the position of the camshaft. This can lead to a variety of engine performance problems.

How the Cam Sensor Works: The Technology Behind the Signal

Most cam sensors used in the 2006 Maxima are Hall effect sensors. This type of sensor relies on the Hall effect, which is the production of a voltage difference across an electrical conductor, transverse to an electric current in the conductor and a magnetic field perpendicular to the current. Here's a simplified explanation:

- A Rotating Target: A toothed wheel (or a wheel with strategically placed magnets) is attached to the camshaft. As the camshaft rotates, so does this wheel.

- Magnetic Field: The sensor itself contains a permanent magnet.

- Hall Effect Chip: A semiconductor chip (the Hall effect sensor) sits within the magnetic field.

- Signal Generation: As the teeth (or magnets) on the rotating wheel pass the sensor, they disrupt the magnetic field. This disruption causes a change in the voltage output of the Hall effect sensor.

- ECU Interpretation: The ECU interprets these voltage changes as the camshaft's position. The pattern of voltage pulses corresponds to the different positions of the camshaft.

Some older vehicles, like certain early 1990s Honda Accords, used a different type of cam sensor called an optical sensor. These sensors used a light beam and a slotted disc to detect camshaft position. However, Hall effect sensors are generally more robust and reliable, making them the preferred choice for modern vehicles like the 2006 Maxima.

Symptoms of a Failing Cam Sensor in a 2006 Nissan Maxima

A failing cam sensor can cause a range of symptoms, some more obvious than others. Here are some common signs to watch out for:

- Check Engine Light: This is often the first indication that something is wrong. The ECU will typically store a diagnostic trouble code (DTC) related to the cam sensor, such as P0340 ("Camshaft Position Sensor Circuit Malfunction") or P0345 ("Camshaft Position Sensor A Circuit Malfunction (Bank 2)"). It's crucial to have the code read by a scan tool to confirm the issue.

- Engine Stalling: The engine may stall unexpectedly, especially at idle or low speeds. This is because the ECU is not receiving accurate camshaft position information, leading to improper fuel injection or ignition timing.

- Rough Idling: The engine may idle roughly, with noticeable vibrations or shaking. This can be due to misfires caused by incorrect timing.

- Hard Starting or No Starting: In some cases, a completely failed cam sensor can prevent the engine from starting at all. The ECU may not allow fuel injection or spark if it doesn't receive a valid signal from the cam sensor.

- Reduced Engine Performance: You may notice a decrease in power, acceleration, and fuel economy. The engine might feel sluggish or hesitant.

- Engine Misfires: A faulty cam sensor can cause the engine to misfire, leading to a loss of power and increased emissions. This is especially noticeable during acceleration.

It's important to note that these symptoms can also be caused by other problems, such as a faulty crank sensor, a clogged fuel filter, or a vacuum leak. Therefore, proper diagnosis is essential.

Diagnosing a 2006 Nissan Maxima Cam Sensor Problem

Diagnosing a cam sensor problem requires a systematic approach. Here are some steps you can take:

- Read the Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve any stored DTCs from the ECU. This will provide valuable clues about the nature of the problem. Common codes related to the cam sensor include P0340, P0341, P0342, P0343, P0344, P0345, P0346, P0347, P0348, and P0349. Note which bank the code refers to (Bank 1 or Bank 2), as the Maxima has two camshafts (and potentially two cam sensors).

- Visual Inspection: Inspect the cam sensor and its wiring harness for any obvious signs of damage, such as cracked plastic, frayed wires, or corrosion. Make sure the connector is securely attached to the sensor.

- Wiring Continuity Test: Use a multimeter to check the continuity of the wires connecting the cam sensor to the ECU. Refer to the vehicle's wiring diagram to identify the correct wires.

- Sensor Output Voltage Test: With the engine running (if possible), use a multimeter to measure the voltage output of the cam sensor. Compare the reading to the manufacturer's specifications. A fluctuating voltage indicates that the sensor is at least attempting to function. A consistently high or low voltage suggests a problem.

- Oscilloscope Test (Advanced): An oscilloscope can be used to visualize the cam sensor's signal waveform. This allows you to see the shape and timing of the signal, which can reveal subtle problems that might not be apparent with a multimeter. This method requires more specialized equipment and knowledge.

Important Safety Tip: Disconnect the negative battery cable before working on any electrical components of your vehicle.

Replacing the Cam Sensor on a 2006 Nissan Maxima

Replacing a cam sensor is generally a straightforward task, but it's important to follow these steps:

- Gather Your Tools and Parts: You'll need a new cam sensor, sockets, wrenches, a ratchet, and potentially a torque wrench. Be sure to purchase the correct sensor for your 2006 Nissan Maxima. Check parts diagrams to verify the correct location.

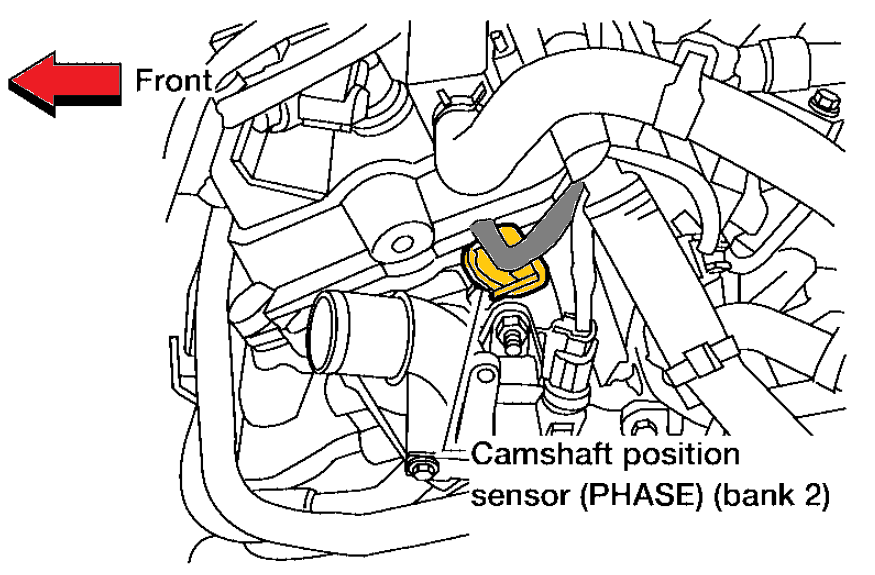

- Locate the Cam Sensor: The cam sensor is typically located on the engine block near the camshaft. Consult your vehicle's repair manual or online resources to find the exact location. On the 2006 Maxima, there will be one sensor per cylinder bank, so identifying the correct bank from your diagnostic code is important.

- Disconnect the Wiring Harness: Disconnect the electrical connector from the old cam sensor. Be careful not to damage the connector or the wiring.

- Remove the Old Sensor: Use a socket or wrench to remove the bolt or bolts holding the sensor in place. Gently pull the sensor out of the engine block.

- Install the New Sensor: Insert the new cam sensor into the engine block. Make sure it's properly seated.

- Tighten the Mounting Bolts: Tighten the mounting bolts to the specified torque. Overtightening can damage the sensor or the engine block.

- Reconnect the Wiring Harness: Reconnect the electrical connector to the new cam sensor. Make sure it's securely attached.

- Clear the Diagnostic Trouble Codes: Use an OBD-II scanner to clear any stored DTCs from the ECU.

- Test Drive the Vehicle: Take the vehicle for a test drive to ensure that the problem has been resolved.

Practical Takeaways

- Know the Symptoms: Be aware of the symptoms of a failing cam sensor, such as a check engine light, engine stalling, rough idling, and reduced performance.

- Read the Codes: Use an OBD-II scanner to read any stored DTCs. This will help you pinpoint the problem.

- Inspect the Wiring: Visually inspect the cam sensor and its wiring harness for any signs of damage.

- Test the Sensor: Use a multimeter to test the sensor's output voltage.

- Replace if Necessary: If the cam sensor is faulty, replace it with a new one.

- Consider a Professional: If you're not comfortable performing the diagnosis or replacement yourself, take the vehicle to a qualified mechanic.

- Preventative Maintenance: While not strictly preventative maintenance, regular oil changes help maintain optimal engine health, which can indirectly affect the lifespan of sensors like the cam sensor. Clean oil helps prevent sludge buildup, which could potentially interfere with the sensor's operation.

Understanding the function and potential issues with the cam sensor in your 2006 Nissan Maxima will empower you to diagnose problems more effectively and make informed decisions about repairs. By being proactive and addressing these issues promptly, you can keep your Maxima running smoothly and reliably for years to come.