2007 Nissan Altima 02 Sensor

The 2007 Nissan Altima, like many modern vehicles, relies heavily on its oxygen (O2) sensors to maintain optimal engine performance, fuel efficiency, and emissions control. These seemingly small components play a crucial role in the feedback loop that governs the air-fuel mixture. Understanding how they function, their types, and potential issues can be incredibly valuable for any car enthusiast or aspiring mechanic. This guide will delve into the technical details of the 2007 Altima's O2 sensor system.

The Role of Oxygen Sensors

At the heart of the combustion process is the precise ratio of air to fuel. This ratio, ideally 14.7 parts air to 1 part fuel by weight (known as the stoichiometric ratio), ensures complete and efficient burning. Deviations from this ratio result in either a rich mixture (excess fuel) or a lean mixture (excess air). Both extremes negatively impact performance, emissions, and can even damage the engine.

O2 sensors are strategically placed in the exhaust system to measure the amount of oxygen present. This information is then relayed to the Engine Control Module (ECM), the car's onboard computer. The ECM uses this data to adjust the fuel injectors, ensuring the engine operates as close to the stoichiometric ratio as possible. Without functioning O2 sensors, the ECM would be operating blind, leading to reduced fuel economy, increased emissions, and potential engine damage.

Types of O2 Sensors in the 2007 Altima

The 2007 Altima typically employs two types of O2 sensors: upstream (also called pre-catalytic converter or air-fuel ratio sensor) and downstream (also called post-catalytic converter) sensors. While both measure oxygen levels, their primary functions differ.

Upstream (Air-Fuel Ratio) Sensor

The upstream sensor, located *before* the catalytic converter, is a wideband sensor, often referred to as an Air-Fuel Ratio (AFR) sensor. Unlike traditional O2 sensors that only indicate whether the mixture is rich or lean, AFR sensors provide a precise measurement of the air-fuel ratio. This allows the ECM to make fine-tuned adjustments to the fuel injectors, resulting in more efficient and cleaner combustion. The upstream sensor is critical for closed-loop fuel control.

Technically, the upstream sensor utilizes a complex electrochemical cell. It contains a Nernst cell and a pump cell. The Nernst cell generates a voltage proportional to the difference in oxygen concentration between the exhaust gas and a reference oxygen concentration. The pump cell then actively pumps oxygen either into or out of a diffusion gap to maintain a stoichiometric mixture within the Nernst cell. The current required by the pump cell is directly proportional to the actual air-fuel ratio in the exhaust stream. This current signal, rather than a simple voltage signal, is what the ECM interprets.

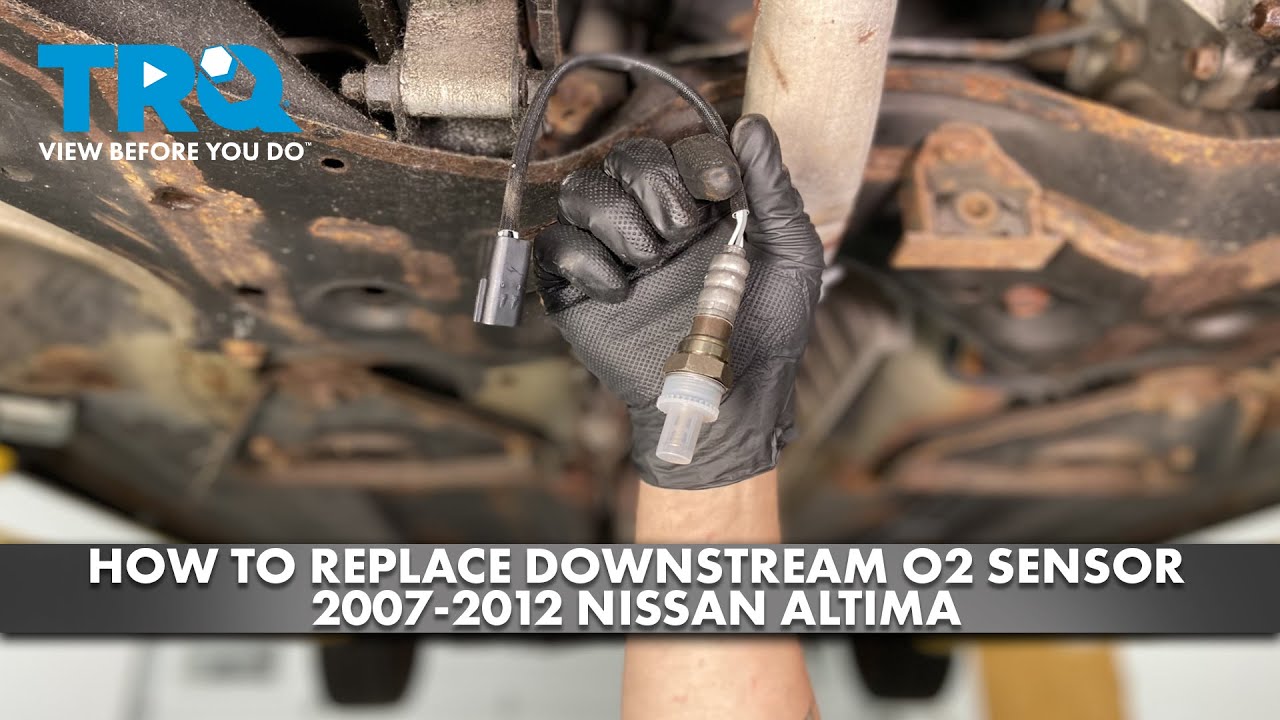

Downstream Sensor

The downstream sensor is positioned *after* the catalytic converter. Its primary function is to monitor the efficiency of the catalytic converter. It doesn't need to be a wideband sensor because its main task is to verify that the catalytic converter is properly reducing pollutants in the exhaust stream. If the downstream sensor detects a similar oxygen level to the upstream sensor, it indicates that the catalytic converter is not functioning correctly.

Downstream sensors typically generate a voltage signal ranging from 0.1 to 0.9 volts. A low voltage (around 0.1V) indicates a lean mixture (high oxygen content), while a high voltage (around 0.9V) indicates a rich mixture (low oxygen content). When the catalytic converter is functioning correctly, the downstream sensor should exhibit a relatively stable voltage, indicating that the converter is effectively storing and releasing oxygen.

Sensor Construction and Operation

Both upstream and downstream O2 sensors rely on a zirconium dioxide (ZrO2) or titanium dioxide (TiO2) ceramic element. This element is coated with a thin layer of platinum, which acts as a catalyst to promote the chemical reactions necessary for oxygen measurement.

The sensor's operation depends on temperature. To achieve accurate readings, the sensor must reach a certain operating temperature, typically around 600°F (315°C). To facilitate rapid warm-up, most modern O2 sensors are equipped with an internal heating element. This heater is powered by the car's electrical system and allows the sensor to quickly reach operating temperature, even during cold starts. The ECM controls the heater circuit, and a fault in the heater circuit will trigger a diagnostic trouble code (DTC).

Troubleshooting O2 Sensor Issues

Several symptoms can indicate a failing O2 sensor, including:

- Poor fuel economy

- Rough idling

- Hesitation or stalling

- Increased emissions

- Check engine light illumination (with specific O2 sensor-related DTCs)

When diagnosing O2 sensor problems, it's essential to use a scan tool to read any stored DTCs. Common O2 sensor-related codes include:

- P0130-P0167: O2 Sensor Circuit Malfunction (Bank 1 Sensor 1, Bank 1 Sensor 2, etc.)

- P0171: System Too Lean (Bank 1)

- P0172: System Too Rich (Bank 1)

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

However, it's crucial to remember that these codes may not always indicate a faulty O2 sensor. Other issues, such as vacuum leaks, faulty fuel injectors, or exhaust leaks, can also trigger similar codes. Therefore, a thorough diagnostic process is necessary.

Here's a basic troubleshooting process:

- Read and record all DTCs: This provides a starting point for the diagnosis.

- Inspect the sensor wiring and connectors: Look for any signs of damage, corrosion, or loose connections.

- Check the sensor's resistance: Use a multimeter to measure the resistance of the heater circuit. Compare the reading to the manufacturer's specifications.

- Monitor the sensor's output voltage: Use a scan tool to monitor the sensor's output voltage while the engine is running. The upstream sensor should exhibit rapid voltage fluctuations, while the downstream sensor should be relatively stable. If the sensor is sluggish or unresponsive, it may be faulty.

- Perform a smoke test: This can help identify any vacuum leaks that could be affecting the air-fuel mixture.

- Check for exhaust leaks: Exhaust leaks *before* the O2 sensor can introduce extra oxygen and skew the sensor readings.

If all other potential causes have been ruled out, and the O2 sensor is still suspected of being faulty, it may be necessary to replace it. When replacing an O2 sensor, it's crucial to use a high-quality replacement that is specifically designed for the 2007 Nissan Altima. Generic or universal O2 sensors may not provide accurate readings or function properly.

Catalytic Converter Efficiency and O2 Sensor Data

The P0420 code (Catalyst System Efficiency Below Threshold) warrants special attention. While it *can* indicate a failing catalytic converter, it's often triggered by issues with the upstream O2 sensor. If the upstream sensor is providing inaccurate readings, the ECM may incorrectly adjust the fuel mixture, leading to excessive emissions that overwhelm the catalytic converter. In such cases, replacing the upstream O2 sensor may resolve the P0420 code without requiring catalytic converter replacement.

To diagnose a P0420 code, compare the activity of the upstream and downstream O2 sensors. A healthy catalytic converter will significantly dampen the fluctuations observed by the downstream sensor. If the downstream sensor mirrors the upstream sensor's activity, the catalytic converter is likely not functioning efficiently. However, remember to always address any potential upstream O2 sensor issues *before* condemning the catalytic converter.

Conclusion

The oxygen sensors in the 2007 Nissan Altima are critical components that play a vital role in engine management and emissions control. Understanding their function, types, and potential issues can empower car owners and enthusiasts to diagnose and resolve problems effectively. By following a systematic troubleshooting process and using the right tools, you can ensure that your Altima's O2 sensors are functioning optimally, contributing to improved fuel economy, reduced emissions, and a smoother driving experience. Ignoring O2 sensor issues can lead to more severe engine problems down the road, making proactive maintenance and timely repairs essential.