2007 Nissan Frontier Camshaft Position Sensor Location

The 2007 Nissan Frontier, a mid-size pickup truck known for its ruggedness and reliability (especially when properly maintained), houses a critical component for engine management: the camshaft position sensor. This sensor plays a vital role in ensuring the engine runs smoothly and efficiently. Knowing its location, function, and potential issues is crucial for both DIY enthusiasts and professional mechanics. This article will delve into the specifics of the 2007 Frontier's camshaft position sensor, focusing on its location, common problems, and replacement procedures.

Understanding the Camshaft Position Sensor (CMP)

Before diving into the specifics of the 2007 Frontier, let's briefly define what a camshaft position sensor (CMP) actually does. The CMP sensor monitors the position of the camshaft, relaying this information to the engine control unit (ECU), which is the brain of the engine. The ECU uses this data, along with information from the crankshaft position sensor (CKP), to precisely time fuel injection and ignition. Without accurate CMP data, the engine won't run correctly, if at all. Common symptoms of a faulty CMP sensor include:

- Check Engine Light: This is often the first and most obvious sign. Diagnostic trouble codes (DTCs) such as P0340, P0341, P0342, and P0343 are frequently associated with CMP sensor issues.

- Engine Stalling: The engine may stall unexpectedly, particularly at idle or low speeds.

- Hard Starting: Difficulty starting the engine, or a prolonged cranking period, can also indicate a CMP sensor problem.

- Reduced Fuel Economy: Inaccurate timing can lead to inefficient combustion, resulting in decreased fuel mileage.

- Poor Engine Performance: Hesitation, misfires, and a general lack of power can occur.

The CMP sensor is typically a hall-effect sensor or a magnetic reluctance sensor. Hall-effect sensors use a magnetic field and a semiconductor to detect the passage of a tooth or notch on the camshaft. Magnetic reluctance sensors generate a voltage pulse as a tooth passes by. Both types provide the ECU with the necessary information to determine camshaft position.

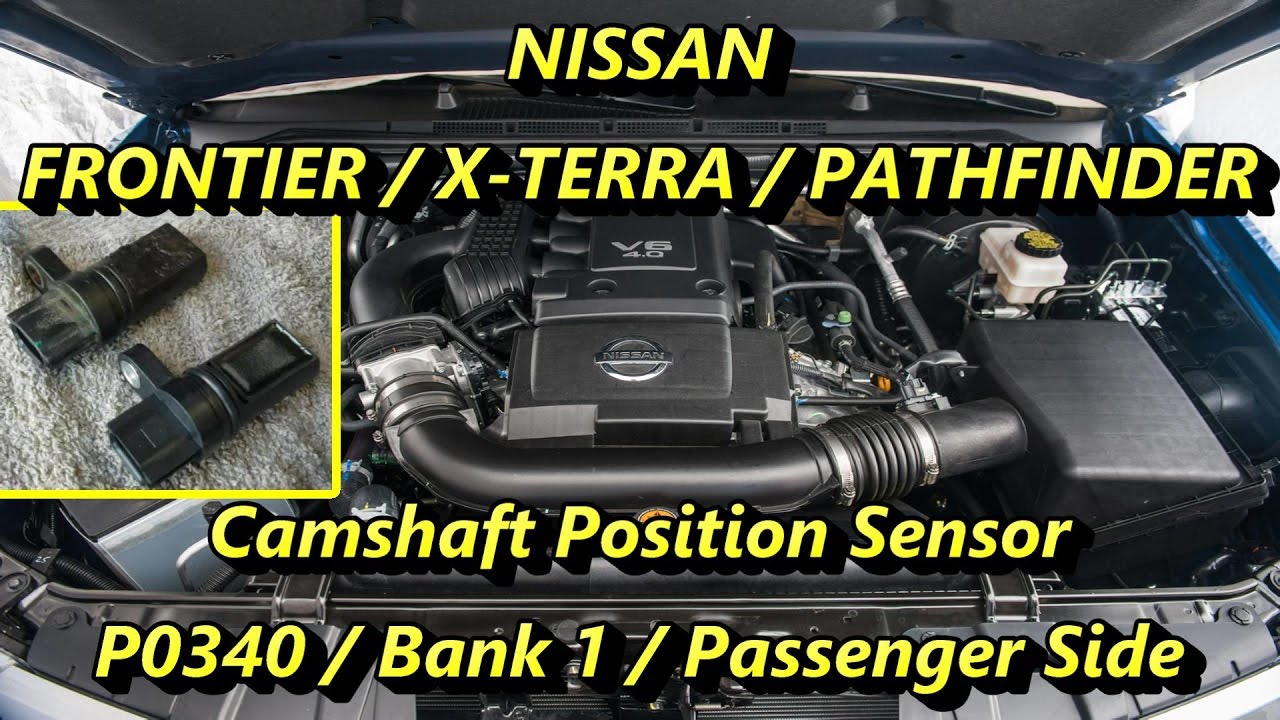

2007 Nissan Frontier Camshaft Position Sensor Location

Now, let's pinpoint the location of the CMP sensor on the 2007 Nissan Frontier. The precise location depends on which engine your Frontier is equipped with. The 2007 Frontier came with two engine options:

- 2.5L QR25DE Inline-4 Cylinder: On the 2.5L engine, the camshaft position sensor is located on the cylinder head, near the valve cover. Specifically, it's typically found towards the front of the engine, accessible without removing major components. It is usually on the intake side of the engine.

- 4.0L VQ40DE V6: For the 4.0L V6 engine, there are actually *two* camshaft position sensors. These are located on the rear of each cylinder head, near the valve covers. One sensor monitors the camshaft position on the driver's side (bank 2), and the other monitors the passenger side (bank 1). Due to their location at the rear of the engine, accessibility can be slightly more challenging than on the 2.5L engine.

Important Note: Always consult your vehicle's repair manual or a reliable online resource (like Alldata or Mitchell OnDemand) to confirm the exact location for your specific engine and model year. While the general location is consistent, minor variations can occur.

To visually locate the sensor, look for a small, cylindrical component with an electrical connector attached. It's usually secured by a single bolt or screw. The connector will have wires leading back to the engine wiring harness.

Replacing the Camshaft Position Sensor on the 2007 Frontier

Replacing a camshaft position sensor is a task that many DIY mechanics can tackle with the right tools and a bit of patience. Here's a general outline of the process:

- Gather Your Tools: You'll need a socket set, wrench set, screwdrivers (both flathead and Phillips head), a new CMP sensor (ensure it's the correct part for your engine), and potentially a scan tool to clear any DTCs after the replacement. Safety glasses and gloves are also recommended.

- Disconnect the Negative Battery Terminal: This is a crucial safety step to prevent electrical shock and accidental damage to the ECU.

- Locate the CMP Sensor: Refer to the location information above, and consult your vehicle's repair manual if needed.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the CMP sensor. Some connectors have a locking tab that needs to be depressed before the connector can be removed.

- Remove the Mounting Bolt/Screw: Use the appropriate socket or wrench to remove the bolt or screw that secures the CMP sensor.

- Remove the Old Sensor: Gently pull the old CMP sensor out of its bore. Note the orientation of the sensor as you remove it, as the new sensor will need to be installed in the same way.

- Install the New Sensor: Insert the new CMP sensor into the bore, ensuring it's properly aligned.

- Secure the Sensor: Tighten the mounting bolt/screw to the specified torque (refer to your repair manual for the correct torque value). Over-tightening can damage the sensor.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the CMP sensor, making sure it's securely attached.

- Reconnect the Negative Battery Terminal: Reconnect the negative battery terminal.

- Clear DTCs: Use a scan tool to clear any diagnostic trouble codes (DTCs) that may have been stored in the ECU.

- Start the Engine and Test: Start the engine and let it idle for a few minutes. Check for any signs of stalling, misfires, or other performance issues.

Important Considerations:

- OEM vs. Aftermarket: While aftermarket CMP sensors are often less expensive, it's generally recommended to use an Original Equipment Manufacturer (OEM) sensor or a reputable aftermarket brand known for quality and reliability. A poor-quality CMP sensor can lead to inaccurate readings and recurring problems.

- Proper Torque: Adhering to the specified torque value for the mounting bolt is critical. Over-tightening can damage the sensor, while under-tightening can cause it to loosen over time.

- Lubrication: Lightly lubricating the O-ring (if equipped) on the new sensor with clean engine oil can help with installation and prevent leaks.

Common Problems and Troubleshooting

Even with proper maintenance, CMP sensors can fail over time due to wear and tear, exposure to heat and vibration, and contamination. Here are some common problems and troubleshooting tips:

- Wiring Issues: Check the wiring harness and connector for any signs of damage, corrosion, or loose connections. Damaged wiring can interfere with the sensor's signal and cause false readings.

- Sensor Contamination: Oil leaks or debris can contaminate the CMP sensor, affecting its performance. Clean the sensor and surrounding area, and address any underlying oil leaks.

- Camshaft Damage: In rare cases, damage to the camshaft itself (such as worn lobes or damaged tone rings) can cause CMP sensor issues. This typically requires more extensive engine repairs.

- Incorrect Sensor: Ensure you are using the correct CMP sensor for your engine. Using the wrong sensor can result in inaccurate readings and engine performance problems.

If you suspect a CMP sensor problem, it's essential to diagnose it accurately. A scan tool can be invaluable for reading DTCs and monitoring sensor data. However, interpreting the data and performing further tests (such as checking the sensor's signal with an oscilloscope) may require specialized knowledge and equipment. If you're not comfortable performing these tests, it's best to consult a qualified mechanic.

Maintenance and Prevention

While CMP sensor failure is often unavoidable, there are steps you can take to prolong the sensor's lifespan and prevent premature failure:

- Regular Oil Changes: Maintaining clean engine oil is crucial for protecting all engine components, including the CMP sensor. Dirty oil can lead to sludge buildup and increased wear.

- Address Oil Leaks Promptly: Oil leaks can contaminate the CMP sensor and other engine components. Repair any oil leaks as soon as they're detected.

- Avoid Over-Revving: Excessive engine revving can put undue stress on the camshaft and other engine components, potentially shortening the lifespan of the CMP sensor.

Conclusion

The camshaft position sensor is a critical component for the proper operation of the 2007 Nissan Frontier's engine. Understanding its location, function, and potential problems is essential for both DIY enthusiasts and professional mechanics. By following the guidelines outlined in this article, you can effectively diagnose and address CMP sensor issues, ensuring your Frontier continues to run smoothly and reliably. Remember to always consult your vehicle's repair manual and use caution when working on your vehicle.