2008 Nissan Altima Alternator Connector

The 2008 Nissan Altima, a mid-size sedan known for its reliability and fuel efficiency, employed a specific alternator connector that has become a point of discussion among automotive professionals. This article delves into the technical specifications, engineering considerations, real-world performance, alternatives, reliability aspects, maintenance, and future trends related to the 2008 Altima's alternator connector.

Technical Specifications and Engineering Choices

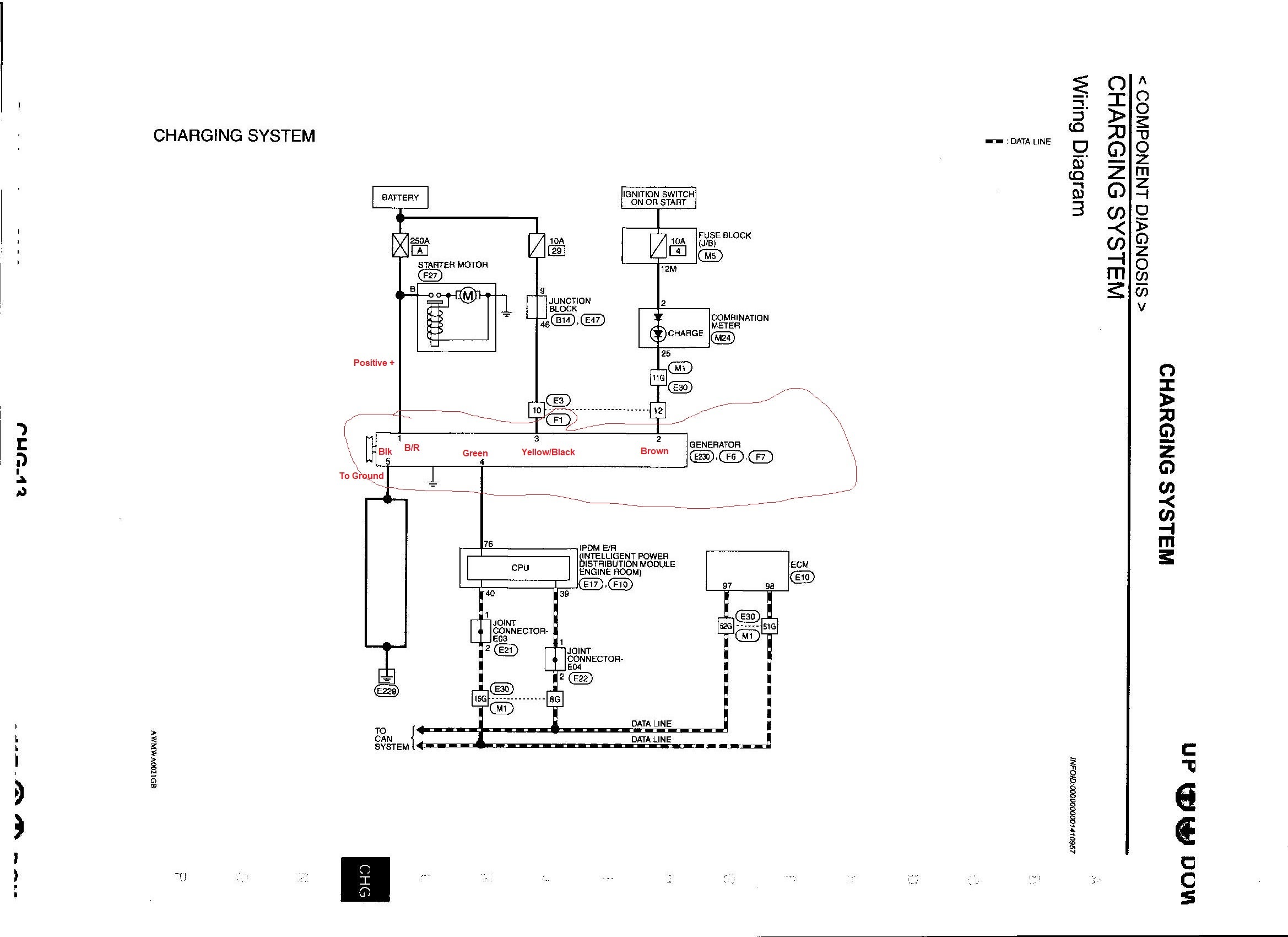

The alternator connector for the 2008 Nissan Altima typically features a 3-pin or 4-pin configuration, depending on the specific engine and trim level. These pins serve distinct purposes:

- Battery Sense (B-Terminal): This pin provides a direct connection to the battery, allowing the alternator to monitor the battery's voltage. This feedback is crucial for regulating the alternator's output and ensuring proper charging.

- Ignition (IG Terminal): This pin receives power when the ignition is turned on, signaling the alternator to begin operating. It acts as the remote turn-on circuit.

- Stator (S Terminal): Some models utilize a stator connection that provides feedback on the alternator's internal load, allowing the PCM (Powertrain Control Module) to monitor alternator performance. This aids in diagnostics and potentially allows for load management.

- Field Control (F Terminal/PCM Controlled): In some advanced alternator systems, this pin is connected to the PCM, allowing the computer to actively control the alternator's output voltage. This is less common in the base model 2008 Altima but appears in higher trim levels or hybrid variants.

The connector housing itself is typically made of a high-temperature, glass-filled nylon or similar polymer material designed to withstand the harsh under-hood environment, including heat, vibration, and exposure to chemicals. The terminals are often constructed from copper alloys, such as brass or phosphor bronze, and are plated with tin or nickel to resist corrosion and ensure good electrical conductivity. The wires leading to the connector are of appropriate gauge to carry the necessary current without excessive voltage drop.

Nissan's engineering choice of using this specific connector type was likely driven by a combination of factors, including cost-effectiveness, ease of assembly, and established reliability within their supply chain. The 3- or 4-pin design provides a sufficient number of connections for the required functionality without being overly complex. The materials used are chosen for durability and resistance to degradation in the engine compartment environment.

Real-World Performance and Comparison with Alternatives

The 2008 Altima's alternator connector generally performs adequately under normal operating conditions. However, it is a common failure point, particularly in older vehicles. The connector is susceptible to:

- Corrosion: Exposure to moisture and road salt can lead to corrosion on the terminals, resulting in poor electrical contact and intermittent charging issues.

- Heat Damage: The engine compartment's high temperatures can cause the plastic connector housing to become brittle and crack, potentially exposing the terminals to the elements or causing them to loosen.

- Vibration: Constant engine vibration can loosen the terminals within the connector, leading to poor contact and eventual failure.

Alternatives to the connector used in the 2008 Altima include more robust, sealed connectors with better environmental protection. For example, Deutsch connectors are known for their durability and resistance to harsh conditions. However, these connectors are often more expensive and may require more specialized tooling for installation. Some aftermarket repair solutions involve replacing the original connector with a generic, higher-quality weather-pack style connector, providing improved protection. Also, many repair shops opt to solder the wires together bypassing the connector completely, which resolves the connectivity issues, but it compromises the repairability of the system in the future.

Pros of the OEM Connector:

- Cost-effective

- Easy to assemble

- Widely available

- Designed to integrate seamlessly with the vehicle's wiring harness

Cons of the OEM Connector:

- Prone to corrosion

- Susceptible to heat damage

- Vulnerable to vibration-induced failures

- Relatively fragile compared to more robust connector designs

Reliability Aspects and Maintenance Tips

The reliability of the 2008 Altima's alternator connector can be improved through proactive maintenance. Here are some key maintenance tips:

- Regular Inspection: Periodically inspect the connector for signs of corrosion, cracking, or loose terminals.

- Cleaning and Lubrication: Clean the terminals with an electrical contact cleaner to remove any corrosion or debris. Apply a dielectric grease to the terminals to prevent future corrosion and improve electrical conductivity.

- Secure Mounting: Ensure the connector is securely mounted to prevent excessive vibration.

- Proper Wiring: Check for any frayed or damaged wires leading to the connector. Repair or replace any damaged wiring as needed.

- Voltage Testing: Use a multimeter to check the voltage at the alternator connector to ensure proper charging voltage. Compare the voltage readings with specifications in the service manual.

When replacing a faulty alternator connector, it is crucial to use a high-quality replacement that meets or exceeds the original manufacturer's specifications. Consider using a connector with improved environmental protection, such as a sealed connector or a connector with a more robust housing. It is also important to properly crimp or solder the wires to the new connector to ensure a reliable electrical connection.

Prevention is always the best approach. Applying dielectric grease to the connector during routine maintenance, even if no issues are present, can significantly extend its lifespan.

Future Trends

Future trends in automotive alternator connectors are likely to focus on increased durability, improved environmental protection, and enhanced diagnostic capabilities. Some potential developments include:

- Sealed Connectors: More widespread adoption of sealed connectors that are resistant to moisture, corrosion, and other environmental factors.

- High-Temperature Materials: Use of more advanced, high-temperature plastics and alloys that can withstand the extreme heat of the engine compartment.

- Integrated Diagnostics: Integration of sensors into the connector to monitor voltage, current, and temperature, providing real-time diagnostic data to the vehicle's control system.

- Wireless Connectivity: Exploration of wireless connectivity options for alternator control and monitoring, potentially eliminating the need for physical wires and connectors altogether.

- Smart Alternators and Load Management: Future vehicles will rely more heavily on smart alternators that communicate with the vehicle's computer to optimize charging based on driving conditions and electrical load. These systems require more sophisticated connectors with additional pins for data communication.

As vehicles become more electrified and incorporate more advanced electronic systems, the demands on alternator connectors will continue to increase. Manufacturers will need to develop connectors that are not only durable and reliable but also capable of handling higher voltages and currents.

Furthermore, the increasing focus on vehicle autonomy and over-the-air updates could lead to the development of connectors that can be remotely diagnosed and even reconfigured, enabling proactive maintenance and preventing potential failures. This would require incorporating communication protocols into the connector design, adding complexity but ultimately improving vehicle reliability.

Conclusion

The 2008 Nissan Altima's alternator connector, while generally reliable, is a common failure point due to its susceptibility to corrosion, heat damage, and vibration. Automotive professionals can improve the connector's lifespan through proactive maintenance, such as regular inspection, cleaning, and lubrication. When replacement is necessary, using a high-quality replacement connector with improved environmental protection is recommended. Looking ahead, future trends in alternator connectors will focus on increased durability, improved environmental protection, enhanced diagnostic capabilities, and seamless integration with advanced vehicle control systems. The automotive industry is constantly evolving, and staying informed about the latest developments in connector technology is essential for automotive professionals to provide high-quality service and maintain the reliability of modern vehicles.

The transition to electric vehicles (EVs) marks a significant shift away from traditional alternator systems. While EVs do not have alternators, they rely on sophisticated charging systems and high-voltage connectors that present their own unique challenges and opportunities. Automotive professionals need to adapt to this changing landscape by acquiring expertise in EV charging infrastructure, battery management systems, and high-voltage connector maintenance.