2009 Nissan Versa Rear Brakes

The 2009 Nissan Versa, a compact hatchback and sedan, relies on a drum brake system in its rear wheels, a relatively simple and robust design that has been a staple in automotive engineering for decades. While disc brakes offer superior performance, especially in stopping power and heat dissipation, drum brakes offer cost-effectiveness and ease of maintenance, making them a suitable choice for the rear axle of many economy vehicles. This in-depth guide explores the mechanics and workings of the 2009 Nissan Versa’s rear drum brakes.

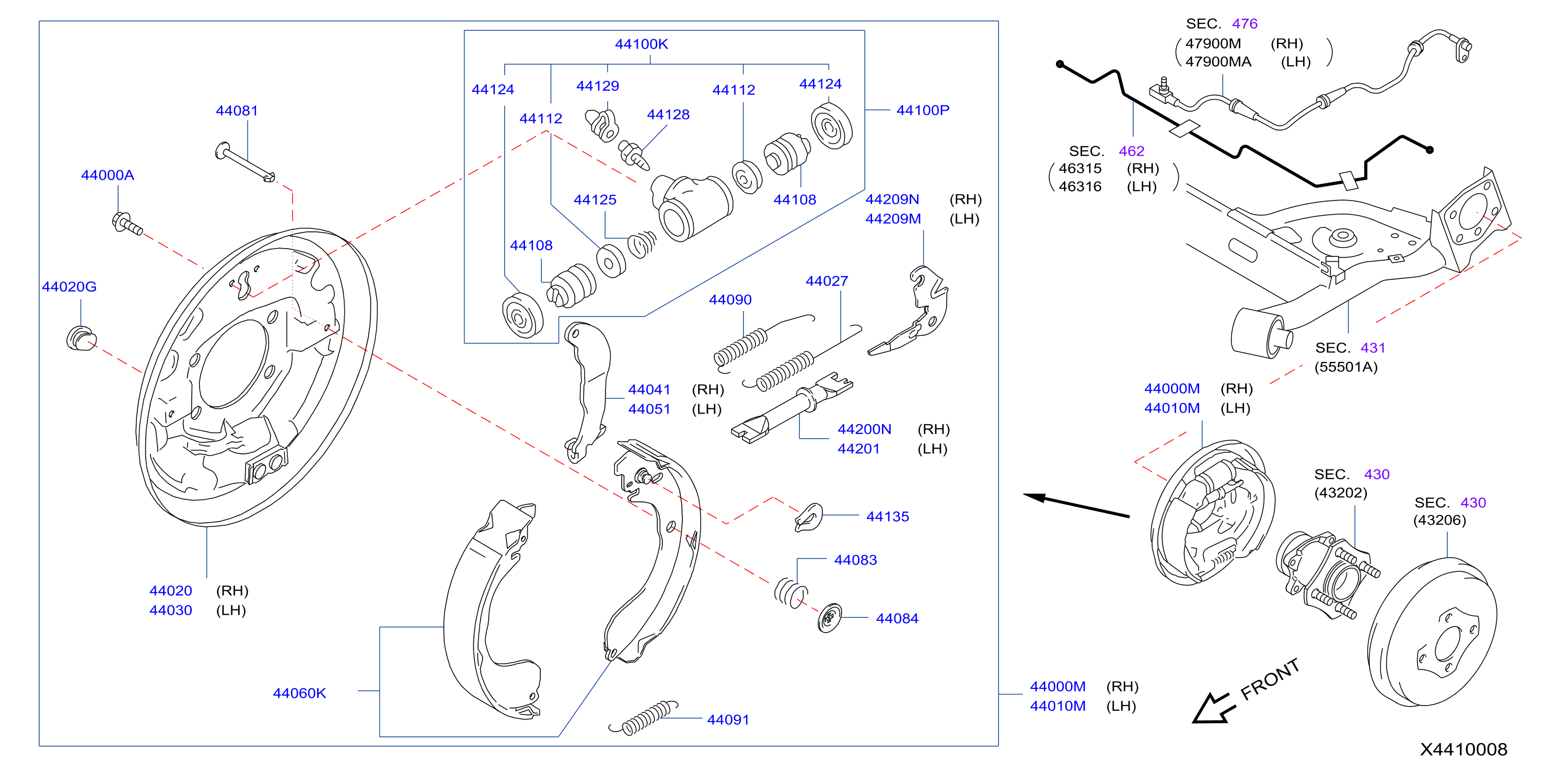

Anatomy of the Drum Brake

At its core, a drum brake system consists of several key components, all working in concert to convert the driver's input into braking force. Understanding each component is crucial to grasping the overall operation of the system. These are the main elements involved in the system:

The Brake Drum

The brake drum is a hollow, cylindrical component that rotates along with the wheel. It's typically made of cast iron and forms the outer surface against which the brake shoes are pressed. The inner surface of the drum is precisely machined to provide a smooth, consistent friction surface.

The Brake Shoes

Inside the drum are two brake shoes, crescent-shaped metal platforms lined with friction material (brake linings). The brake linings are typically made of a composite material designed to withstand high temperatures and provide a high coefficient of friction. These shoes are forced outwards against the inner surface of the drum when the brake pedal is pressed.

The Wheel Cylinder

The wheel cylinder is a hydraulic actuator located at the top of the backing plate. It contains pistons that are forced outwards by hydraulic pressure from the master cylinder when the brake pedal is depressed. These pistons, in turn, push the brake shoes outwards.

The Return Springs

Return springs are responsible for pulling the brake shoes back away from the drum when the brake pedal is released. These springs ensure that the shoes do not drag against the drum when braking is not required, preventing premature wear and reducing fuel consumption.

The Adjuster Mechanism

As the brake linings wear down over time, the distance the shoes need to travel to contact the drum increases. The adjuster mechanism automatically compensates for this wear, maintaining the proper shoe-to-drum clearance and ensuring consistent brake pedal feel. Typically, these systems are star wheel adjusters, and use either an automated or manual system to keep the clearance to the drum appropriate.

The Backing Plate

The backing plate is a stationary metal plate that provides a mounting point for all the other components of the drum brake system, including the wheel cylinder, brake shoes, return springs, and adjuster mechanism.

How Drum Brakes Work: A Step-by-Step Explanation

The operation of the drum brake system can be broken down into a series of steps:

- Brake Pedal Activation: The driver presses the brake pedal, which in turn actuates the master cylinder.

- Hydraulic Pressure: The master cylinder generates hydraulic pressure, which is transmitted through the brake lines to the wheel cylinders at each wheel.

- Wheel Cylinder Activation: The hydraulic pressure entering the wheel cylinder forces its pistons outwards.

- Shoe Expansion: The pistons push the brake shoes outwards, pressing the brake linings against the inner surface of the rotating brake drum.

- Friction and Deceleration: The friction between the brake linings and the drum generates braking force, slowing the rotation of the wheel and bringing the vehicle to a stop.

- Release: When the brake pedal is released, the hydraulic pressure in the system drops.

- Shoe Retraction: The return springs pull the brake shoes back away from the drum.

- Wheel Rotation Resumes: The drum is now free to rotate, and the vehicle can resume its normal speed.

Self-Actuation: A Unique Drum Brake Feature

One characteristic of drum brakes is the phenomenon known as self-actuation or servo action. As the leading shoe (the shoe positioned in the direction of drum rotation) contacts the drum, the friction force tends to pull the shoe further into contact with the drum. This effect amplifies the braking force, requiring less effort from the driver.

However, this self-actuation can also be a drawback. If the linings are contaminated or the drum surface is uneven, the self-actuation effect can lead to uneven braking and brake grabbing. This is why it's crucial to keep the brake components clean and in good condition.

Maintenance and Inspection

Regular inspection and maintenance are essential for ensuring the proper functioning and longevity of the drum brake system. Key maintenance procedures include:

- Lining Inspection: Periodically inspect the brake linings for wear and tear. Replace the linings when they reach the minimum thickness specification.

- Drum Inspection: Check the brake drums for cracks, scoring, or excessive wear. If the drum is damaged beyond repair, it should be replaced. Resurfacing is an option in some cases, but drums have a minimum thickness that shouldn't be violated.

- Hardware Inspection: Inspect the return springs, adjuster mechanism, and other hardware for corrosion or damage. Replace any worn or damaged components.

- Lubrication: Lubricate the moving parts of the adjuster mechanism and the contact points between the shoes and the backing plate with a high-temperature brake lubricant.

- Adjustment: Ensure that the brake shoes are properly adjusted to maintain the correct shoe-to-drum clearance.

- Brake Fluid Flush: Replace brake fluid per manufacturer recommendation to prevent corrosion and maintain consistent brake performance.

Neglecting maintenance can lead to a number of problems, including reduced braking performance, uneven braking, noise, and premature wear of the brake components.

Advantages and Disadvantages of Drum Brakes

Like any engineering design, drum brakes have their own set of advantages and disadvantages:

Advantages:

- Cost-Effective: Generally less expensive to manufacture than disc brakes.

- Simplicity: Relatively simple design, making them easier to maintain and repair.

- Parking Brake Integration: Easily integrates with a parking brake system.

- Reduced Pad Wear: The enclosed nature of drum brakes reduces pad wear from debris on the road.

Disadvantages:

- Heat Dissipation: Poor heat dissipation compared to disc brakes, leading to brake fade under heavy use.

- Water Sensitivity: More susceptible to water contamination, which can reduce braking performance.

- Self-Actuation Issues: Self-actuation can lead to uneven braking and grabbing.

- More Complex Replacement: Replacing linings can be more complex than replacing disc brake pads.

Conclusion

The 2009 Nissan Versa's rear drum brakes, while seemingly simple, represent a carefully engineered solution for providing adequate braking performance at a reasonable cost. Understanding the components, operation, and maintenance requirements of these brakes is key to ensuring their continued reliability and safety. While disc brakes are increasingly common even on smaller vehicles, the drum brake remains a viable and cost-effective option for certain applications, and a thorough understanding of their workings is a valuable asset for any automotive enthusiast or technician. By taking proper care of the drum brake system, owners can ensure that their Versa continues to stop safely and reliably for years to come.