2010 Nissan Altima O2 Sensor

The 2010 Nissan Altima, like most modern vehicles, relies heavily on its oxygen (O2) sensors for optimal engine performance, fuel efficiency, and emissions control. These seemingly small components play a critical role in the engine's feedback loop, constantly monitoring the exhaust gases and providing vital data to the Engine Control Unit (ECU). Understanding how these sensors function, their location, potential failure modes, and basic troubleshooting is crucial for any Altima owner or aspiring automotive enthusiast.

O2 Sensor Fundamentals

At its core, an O2 sensor is an electrochemical device that measures the amount of oxygen present in the exhaust gas stream. This measurement is then converted into an electrical signal – a voltage – that is sent to the ECU. The ECU uses this information to adjust the air-fuel mixture, ensuring that the engine is running at or near its stoichiometric ratio (approximately 14.7:1, air to fuel). This ratio allows the catalytic converter to operate most efficiently, minimizing harmful emissions such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx).

There are typically two types of O2 sensors used in the 2010 Altima: upstream (or pre-catalytic converter) and downstream (or post-catalytic converter) sensors. The upstream sensor's primary function is to provide feedback for fuel trim control, ensuring the engine maintains the ideal air-fuel ratio. The downstream sensor monitors the efficiency of the catalytic converter. It compares the oxygen content of the exhaust gas after it has passed through the converter to the oxygen content before. A properly functioning catalytic converter will significantly reduce the oxygen content. A failing converter will show little or no change, which is detected by the downstream sensor.

Sensor Types and Construction

The 2010 Altima primarily utilizes zirconia O2 sensors, although titanium dioxide sensors might be found in some specific sub-models. Zirconia sensors are the more common type. Let's delve into the workings of a zirconia sensor:

A zirconia O2 sensor consists of a thimble-shaped ceramic element made of zirconium dioxide (ZrO2) coated with platinum electrodes. One side of the element is exposed to the exhaust gas, while the other is exposed to atmospheric air (reference air). Zirconium dioxide becomes an oxygen ion conductor at high temperatures. When there is a difference in oxygen concentration between the exhaust gas and the reference air, oxygen ions migrate through the zirconia element. This migration creates a voltage difference between the platinum electrodes. The higher the oxygen concentration in the exhaust (leaner mixture), the lower the voltage produced. Conversely, a lower oxygen concentration (richer mixture) results in a higher voltage. The ECU interprets this voltage signal and adjusts the fuel injectors accordingly.

Heating elements are also crucial for proper O2 sensor operation. Cold sensors do not function accurately. Most modern O2 sensors, including those in the 2010 Altima, are heated. This heating element brings the sensor to its operating temperature (typically around 600°F or 315°C) quickly, allowing for accurate readings even during cold starts and idling. The heating element is typically a small resistor integrated into the sensor body and powered by the vehicle's electrical system.

Location of O2 Sensors in the 2010 Altima

The precise location of the O2 sensors depends on the engine configuration of your 2010 Altima (2.5L inline-4 or 3.5L V6). Generally, you'll find:

- Upstream O2 sensors: Located in the exhaust manifold, before the catalytic converter. The 2.5L Altima will have one upstream sensor. The 3.5L Altima will have two, one for each bank of cylinders. These are critical for fuel trim adjustments.

- Downstream O2 sensors: Located after the catalytic converter, typically in the exhaust pipe. The 2.5L Altima will have one downstream sensor. The 3.5L Altima will have one or two, depending on the exhaust configuration. These are primarily for monitoring the catalytic converter's efficiency.

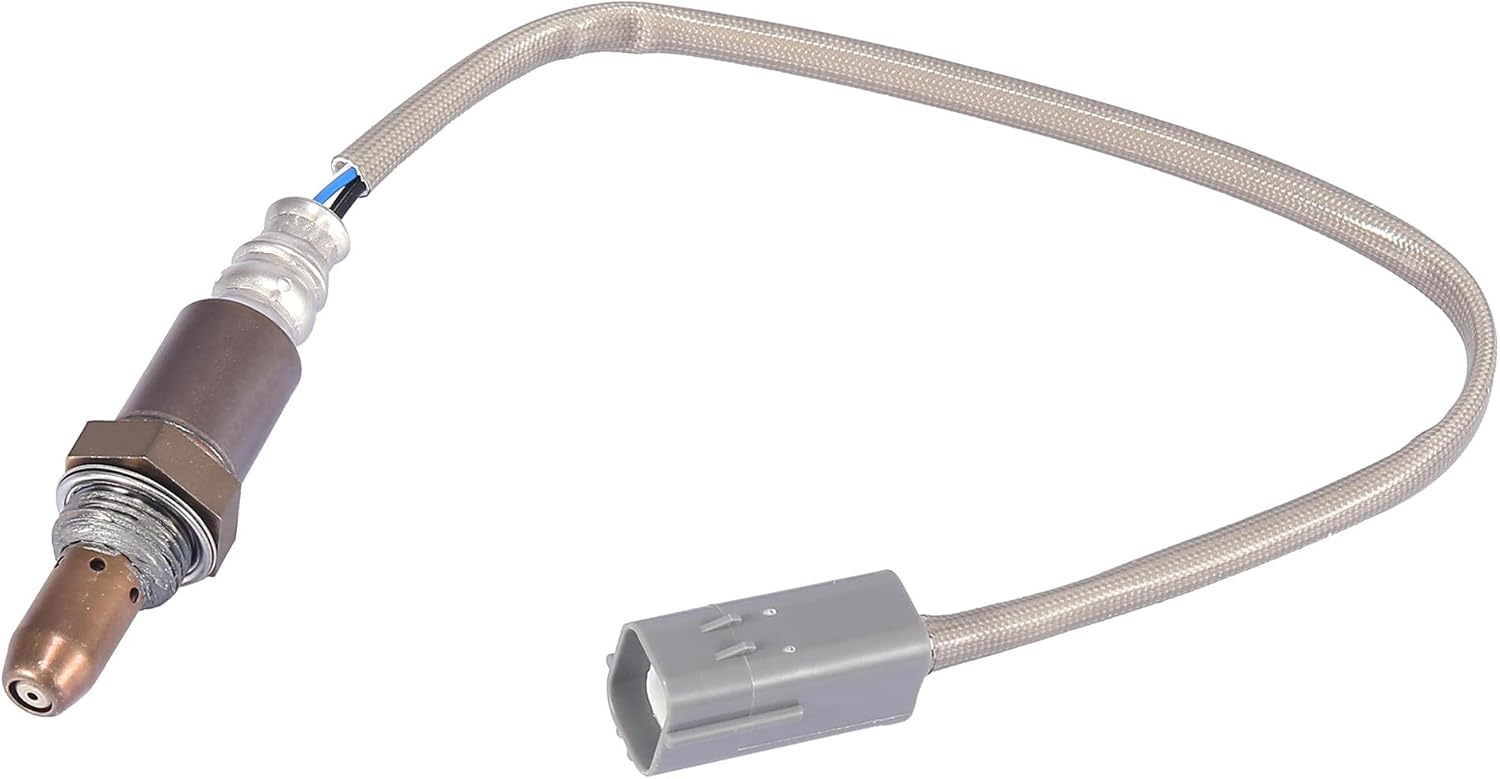

Visually, O2 sensors are typically cylindrical in shape with a wire harness connector. They are threaded into the exhaust system. Identifying the specific sensor (upstream vs. downstream) can be done by tracing the wiring harness to its connection point or by comparing the sensor part numbers.

Common O2 Sensor Problems and Symptoms

O2 sensors operate in a harsh environment, exposed to high temperatures, vibrations, and corrosive exhaust gases. Consequently, they are prone to failure over time. Common problems include:

- Contamination: Oil leaks, coolant leaks, or excessive use of fuel additives can contaminate the sensor element, hindering its ability to accurately measure oxygen levels.

- Carbon fouling: Rich running conditions or excessive idling can lead to carbon deposits on the sensor, affecting its performance.

- Physical damage: Impacts from road debris or improper installation can damage the sensor body or its electrical connections.

- Heater circuit failure: The heating element can fail, causing the sensor to take longer to reach its operating temperature, especially in colder climates.

- Wiring issues: Damaged or corroded wiring and connectors can disrupt the signal flow between the sensor and the ECU.

Symptoms of a faulty O2 sensor can include:

- Check Engine Light (CEL): This is the most common indicator. Diagnostic trouble codes (DTCs) related to O2 sensor performance will be stored in the ECU's memory.

- Poor fuel economy: A faulty upstream sensor can cause the engine to run rich, wasting fuel.

- Rough idling: An inaccurate air-fuel mixture can lead to unstable idling.

- Hesitation or stalling: The engine may hesitate during acceleration or even stall.

- Failed emissions test: A malfunctioning O2 sensor can prevent the catalytic converter from operating efficiently, resulting in high emissions.

- Reduced engine performance: The engine may feel sluggish or lack power.

Diagnosing O2 Sensor Problems

A proper diagnosis is crucial before replacing an O2 sensor. Here are some steps you can take:

- Read the diagnostic trouble codes (DTCs): Use an OBD-II scanner to retrieve the codes stored in the ECU. These codes will provide valuable information about the specific O2 sensor issue. Common codes include P0130-P0167 (O2 sensor circuit malfunction), P0420 (catalytic converter efficiency below threshold), and codes related to heater circuit failures.

- Inspect the sensor wiring and connectors: Look for any signs of damage, corrosion, or loose connections. Use a multimeter to check for continuity and voltage at the sensor connector. Refer to the 2010 Altima's wiring diagram for specific pin assignments and voltage specifications.

- Monitor O2 sensor data with a scan tool: A capable scan tool can display real-time data from the O2 sensors, allowing you to observe their voltage fluctuations. Upstream sensors should fluctuate rapidly between approximately 0.1V and 0.9V as the ECU adjusts the fuel mixture. Downstream sensors should exhibit a more stable voltage, indicating a consistent oxygen level after the catalytic converter.

- Check for exhaust leaks: Exhaust leaks upstream of the O2 sensor can introduce false oxygen readings, leading to incorrect fuel trim adjustments.

- Inspect for vacuum leaks: Vacuum leaks can cause a lean condition, affecting the O2 sensor readings.

Important Note: Before replacing an O2 sensor, it's crucial to address any underlying issues that may have caused the failure in the first place. For example, if an oil leak is contaminating the sensor, replacing the sensor without fixing the leak will only result in another failure.

Replacing an O2 Sensor

Replacing an O2 sensor is a relatively straightforward task for a DIY mechanic with basic tools and knowledge. However, it's essential to follow these steps carefully:

- Gather the necessary tools: You'll need an O2 sensor socket (a special socket with a slot for the sensor wiring), a ratchet, an extension, a torque wrench, penetrating oil, and possibly a wire brush.

- Disconnect the negative battery terminal: This will prevent electrical shocks and accidental damage to the ECU.

- Locate the faulty O2 sensor: Refer to the vehicle's service manual or online resources to identify the correct sensor.

- Apply penetrating oil: Spray penetrating oil around the sensor threads to loosen it. Let it soak for at least 15-30 minutes.

- Disconnect the sensor connector: Unplug the electrical connector from the sensor.

- Remove the old sensor: Use the O2 sensor socket and ratchet to carefully unscrew the sensor. Be careful not to strip the threads in the exhaust manifold.

- Clean the threads: Use a wire brush to clean the threads in the exhaust manifold.

- Apply anti-seize compound: Apply a small amount of anti-seize compound to the threads of the new sensor (if it's not pre-coated). This will prevent the sensor from seizing in the exhaust system in the future. Do not get anti-seize on the sensor element itself.

- Install the new sensor: Hand-tighten the new sensor into the exhaust manifold, then use the torque wrench to tighten it to the manufacturer's specified torque (typically around 30-35 lb-ft).

- Connect the sensor connector: Plug the electrical connector into the new sensor.

- Reconnect the negative battery terminal: Reconnect the negative battery terminal.

- Clear the DTCs: Use an OBD-II scanner to clear the diagnostic trouble codes from the ECU.

- Test drive the vehicle: Take the vehicle for a test drive to ensure that the new sensor is functioning correctly and that the check engine light does not reappear.

Important Safety Note: The exhaust system can be extremely hot. Allow the engine to cool completely before working on the O2 sensors.

Conclusion

The O2 sensors are essential components in the 2010 Nissan Altima's engine management system. By understanding their function, location, potential problems, and diagnostic procedures, you can effectively troubleshoot and maintain these critical sensors, ensuring optimal engine performance, fuel efficiency, and emissions control. Regular inspection and timely replacement of faulty O2 sensors can significantly improve the overall reliability and longevity of your Altima.