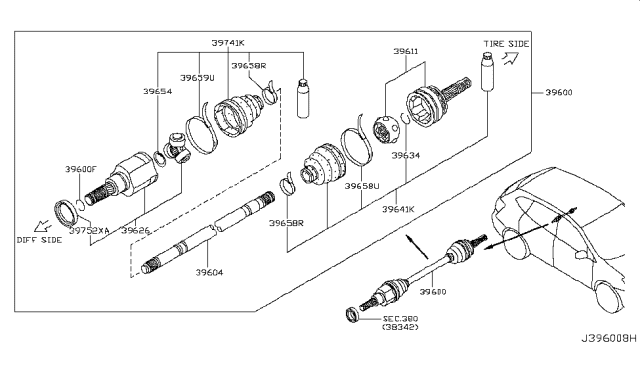

2010 Nissan Rogue Drive Shaft

The humble drive shaft. For those of us who remember the 2010 Nissan Rogue, it might conjure up memories of routine maintenance, perhaps even a repair bill or two. But let's not dwell on the past. Instead, let's use that familiar component as a springboard to discuss the radical transformation happening in the automotive world, a transformation that's reimagining mobility as we know it. The 2010 Rogue, with its conventional internal combustion engine and traditional drivetrain, represents a chapter that is rapidly closing.

The Electric Revolution: A Different Kind of Torque

The most obvious shift is the relentless march of electric vehicles (EVs). Battery technology is improving at an accelerating pace, delivering longer ranges, faster charging times, and lower costs. Companies like Tesla, Rivian, Lucid, and even legacy automakers are pouring billions into EV development, and the results are becoming increasingly compelling. The very architecture of EVs challenges the need for components like the traditional drive shaft in many applications. Think about it: an electric motor can be placed directly on the axle, delivering instantaneous torque with unmatched efficiency. This eliminates the long, rotating shaft that transmits power from the engine to the wheels, simplifying the powertrain and reducing weight. This isn't just about cleaner emissions; it's about a fundamentally different driving experience: smooth, responsive, and remarkably quiet.

However, let’s temper the excitement with a dose of reality. The widespread adoption of EVs faces significant hurdles. The charging infrastructure needs substantial investment to support a fully electric fleet. Battery supply chains are vulnerable and need diversification. The cost of raw materials, like lithium and cobalt, remains a concern. And, let's not forget the psychological barrier of range anxiety – the fear of running out of power before reaching a charging station. Overcoming these challenges requires a concerted effort from governments, automakers, and consumers alike. Innovation in battery technology, particularly solid-state batteries with increased energy density and improved safety, will be crucial.

Hybrid Systems: Bridging the Gap

While EVs are the long-term goal for many, hybrid systems offer a pragmatic and increasingly sophisticated bridge to a fully electric future. Hybrid technology has matured significantly since the early days of the Toyota Prius. Today's hybrids offer impressive fuel efficiency, reduced emissions, and a noticeable boost in performance thanks to the instant torque provided by electric motors. From mild hybrids to plug-in hybrids (PHEVs), there's a hybrid solution to suit a variety of driving needs. PHEVs, in particular, offer the best of both worlds: the ability to drive short distances on electric power alone, coupled with the range and convenience of a gasoline engine for longer trips.

In the context of the drive shaft, hybrid systems present an interesting evolution. While some hybrids retain a traditional drive shaft configuration, others utilize more complex power distribution systems that blend electric and internal combustion power in novel ways. Four-wheel drive hybrids, for example, may use an electric motor to power the rear wheels, eliminating the need for a mechanical connection to the front axle. This opens up possibilities for sophisticated torque vectoring and improved handling. However, the complexity of these hybrid powertrains adds to the cost and can potentially impact reliability. Streamlining the integration of electric and internal combustion components is a key area of ongoing development.

Smart Automotive Solutions: Beyond the Powertrain

The transformation of mobility extends far beyond the powertrain. Smart automotive solutions are reshaping the driving experience in profound ways. Advanced Driver-Assistance Systems (ADAS), such as adaptive cruise control, lane keep assist, and automatic emergency braking, are becoming increasingly commonplace, enhancing safety and convenience. Self-driving technology, while still in its early stages, holds the promise of revolutionizing transportation, particularly in urban environments. Imagine a future where autonomous vehicles optimize traffic flow, reduce congestion, and eliminate accidents. This vision, however, relies on overcoming significant technological, regulatory, and ethical hurdles.

Data is the lifeblood of smart automotive solutions. Vehicles are becoming increasingly connected, generating vast amounts of data that can be used to improve everything from navigation and traffic management to predictive maintenance and personalized in-car experiences. But this data also raises serious privacy concerns. Protecting consumer data and ensuring cybersecurity are paramount. The automotive industry must adopt robust data security protocols and be transparent about how vehicle data is collected, used, and shared.

The Role of Materials and Manufacturing

Underlying all these advancements are significant innovations in materials science and manufacturing processes. Lighter, stronger materials, such as carbon fiber and advanced alloys, are being used to reduce vehicle weight and improve fuel efficiency. Additive manufacturing, or 3D printing, is enabling the creation of complex parts with unprecedented precision and customization. The integration of sensors and electronics into vehicle components is blurring the lines between hardware and software. Even the humble drive shaft itself is benefiting from these advances, with lighter and more durable designs that improve performance and reduce noise, vibration, and harshness (NVH). As vehicles become more complex, the need for advanced manufacturing techniques and skilled technicians will only increase.

Challenges and Opportunities

The automotive industry faces numerous challenges in navigating this period of rapid change. The cost of developing new technologies is substantial, and the return on investment is uncertain. The industry must also adapt to changing consumer preferences, particularly among younger generations who are more likely to prioritize mobility services over car ownership. Furthermore, the shift to electric vehicles and autonomous driving will have a significant impact on the workforce, requiring retraining and upskilling to prepare workers for new roles in software development, data analysis, and advanced manufacturing.

However, these challenges also present tremendous opportunities. The transition to electric mobility can create new jobs in battery manufacturing, charging infrastructure, and renewable energy. The development of autonomous driving technology can lead to safer and more efficient transportation systems. And the increasing connectivity of vehicles can unlock new business models and revenue streams. The key to success lies in embracing innovation, fostering collaboration, and adapting to the evolving needs of consumers.

The automotive industry is on the cusp of a new era, one characterized by electric propulsion, autonomous driving, and connected services. The 2010 Nissan Rogue's drive shaft might seem like a relic of the past, but it serves as a reminder of how far we've come and how much further we have to go.

We are moving from a world where driving is solely about getting from point A to point B to a world where mobility is an integrated, personalized, and sustainable experience. And if you are still concerned about the 2010 Nissan Rogue Drive Shaft? Don't be! It served its purpose. Parts are still available if you need them.

A Visionary Note

Imagine a future where transportation is seamless, intelligent, and invisible. Where autonomous vehicles anticipate our needs, whisking us away to our destinations with effortless grace. Where traffic jams are a distant memory, and urban landscapes are transformed by the absence of parked cars. Where electric vehicles are powered by renewable energy, creating a truly sustainable transportation ecosystem. This future is not a fantasy; it's a goal we can achieve through continued innovation, collaboration, and a shared commitment to building a better world. The drive shaft, in its future iterations, whether physical or conceptual, will be a vital, yet perhaps unseen, component in that grand design. This is not just about building better cars; it's about reimagining the very fabric of our society and how we move within it.