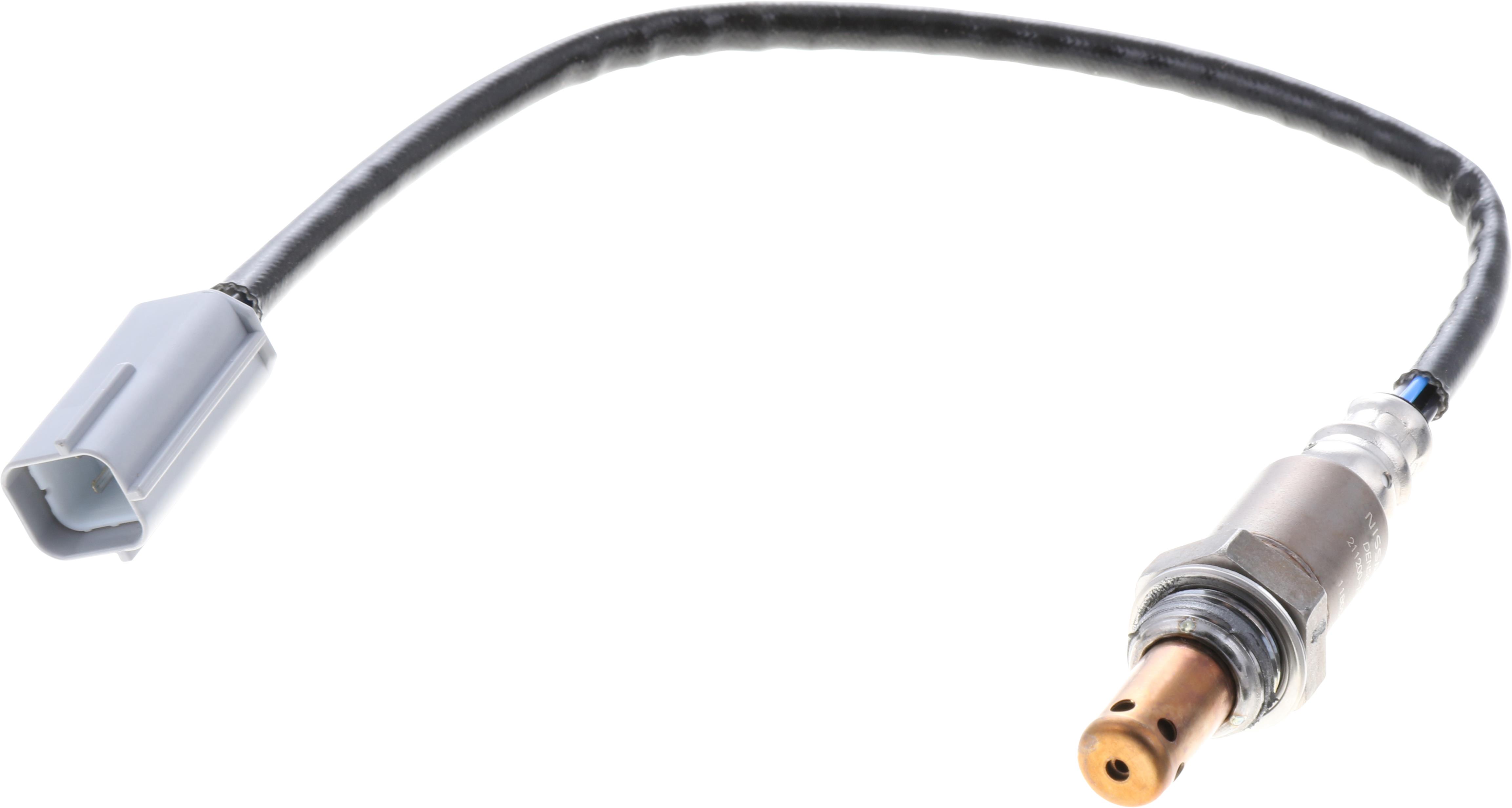

2011 Nissan Altima O2 Sensor

The 2011 Nissan Altima, a mainstay in the mid-size sedan market, relies on a carefully calibrated engine management system to achieve optimal fuel efficiency and emissions control. A critical component of this system is the oxygen (O2) sensor, specifically the upstream and downstream sensors. This article provides an in-depth look at the 2011 Altima's O2 sensor technology, covering technical specifications, engineering choices, real-world performance, comparisons with alternatives, reliability aspects, maintenance tips, and future trends.

Technical Specifications and Sensor Types

The 2011 Altima typically utilizes two types of O2 sensors: upstream (air-fuel ratio sensor) and downstream (catalytic converter monitor). The upstream sensor, located before the catalytic converter, is often a wideband air-fuel ratio sensor on the 2.5L engine and sometimes on the 3.5L V6, although zirconia sensors are also found. These sensors provide real-time data about the air-fuel mixture entering the engine. The downstream sensor, positioned after the catalytic converter, is a standard zirconia sensor. Its primary function is to monitor the converter's efficiency by comparing its oxygen levels to the upstream sensor.

Upstream (Air-Fuel Ratio) Sensor:

- Type: Wideband or Zirconia

- Function: Measures the air-fuel ratio in the exhaust gas stream before the catalytic converter.

- Output: Variable voltage or current signal, representing the air-fuel ratio. Wideband sensors offer a wider range and faster response time compared to traditional zirconia sensors.

- Wiring: Typically 4-5 wires (heater circuit, sensor signal, ground, and sometimes a calibration wire).

Downstream (Catalytic Converter Monitor) Sensor:

- Type: Zirconia

- Function: Monitors the oxygen storage capacity of the catalytic converter by comparing oxygen levels to the upstream sensor.

- Output: Voltage signal (typically 0-1 volt), indicating oxygen content.

- Wiring: Typically 3-4 wires (heater circuit, sensor signal, and ground).

The heater circuit in both sensor types is crucial for proper operation, especially during cold starts. It brings the sensor to its operating temperature (typically around 600°F) quickly, ensuring accurate readings and reducing emissions.

Engineering Choices and Rationale

Nissan's choice of sensor types reflects a balance between cost, performance, and regulatory compliance. The use of wideband sensors upstream allows for more precise air-fuel ratio control, leading to improved fuel economy and reduced emissions. While zirconia sensors are less expensive, wideband sensors provide a significant advantage in modern engine management systems that demand quick and accurate feedback.

The location of the sensors is also strategically chosen. The upstream sensor must be positioned close to the exhaust manifold to provide timely data to the ECU. The downstream sensor's placement after the catalytic converter is essential for monitoring the converter's performance. The ECU compares the signals from both sensors to determine if the catalytic converter is functioning correctly. A failing converter will result in similar signals from both sensors, indicating that the converter is not effectively reducing pollutants.

The materials used in the sensors are also carefully selected to withstand the harsh environment of the exhaust system. Zirconia, a ceramic material, is known for its durability and ability to conduct oxygen ions at high temperatures. The sensor's protective housing shields the internal components from contaminants and extreme temperatures.

Real-World Performance and Diagnostic Considerations

In the real world, the O2 sensors play a vital role in maintaining the 2011 Altima's performance and fuel efficiency. A faulty O2 sensor can lead to a variety of issues, including:

- Reduced fuel economy

- Increased emissions

- Rough idling

- Hesitation during acceleration

- Check engine light (CEL) illumination with diagnostic trouble codes (DTCs) such as P0130-P0167 (O2 sensor circuit malfunctions), P0420 (Catalyst System Efficiency Below Threshold)

Diagnosing O2 sensor problems requires a scan tool to read DTCs and monitor sensor data. Technicians should look for:

- Slow response times

- Sticking at certain voltage levels

- Inconsistent readings

- Failure to heat up properly

It's crucial to inspect the sensor wiring and connectors for damage, corrosion, or loose connections. A visual inspection can often reveal obvious problems. Using a multimeter to check the heater circuit resistance is also a good practice. Correct heater resistance values vary by manufacturer and sensor type but are typically in the range of 2-15 ohms.

It's important to remember that other engine problems, such as vacuum leaks or fuel injector issues, can also cause O2 sensor-related DTCs. Therefore, a thorough diagnostic process is essential to identify the root cause of the problem.

Comparison with Alternatives

Alternatives to the factory-installed O2 sensors include aftermarket sensors from various manufacturers. These sensors can vary significantly in quality and performance.

Pros of Aftermarket O2 Sensors:

- Lower cost (in some cases)

- Wider availability

Cons of Aftermarket O2 Sensors:

- Potentially lower quality and shorter lifespan

- Inaccurate readings

- Compatibility issues with the vehicle's ECU

- May not meet OEM specifications

O2 Sensor Brand Comparison:

Denso and Bosch: Often considered OEM suppliers and generally provide reliable performance. They tend to be more expensive than other aftermarket brands, but the quality is typically higher.

NTK (NGK): Another reputable brand with a good track record for O2 sensor performance and durability.

Other Aftermarket Brands: Can be significantly cheaper but may have inconsistent quality. Research and customer reviews are essential before purchasing.

While aftermarket sensors can be a cost-effective option, it's generally recommended to use OEM or reputable brands to ensure proper function and longevity. A faulty or inaccurate O2 sensor can lead to more serious engine problems down the road.

Reliability Aspects and Maintenance Tips

The lifespan of an O2 sensor can vary depending on driving conditions, fuel quality, and maintenance practices. Generally, O2 sensors are expected to last between 60,000 and 100,000 miles. However, certain factors can shorten their lifespan:

- Contamination: Oil leaks, coolant leaks, and excessive use of fuel additives can contaminate the sensor and reduce its accuracy.

- Overheating: Engine misfires and other issues can cause the sensor to overheat, leading to premature failure.

- Poor Fuel Quality: Fuel containing excessive sulfur or other contaminants can damage the sensor.

Maintenance Tips:

- Use high-quality fuel.

- Address engine misfires promptly.

- Repair any oil or coolant leaks that could contaminate the sensor.

- Avoid excessive use of fuel additives.

- Consider replacing O2 sensors as part of a preventative maintenance schedule (around 80,000 miles).

When replacing O2 sensors, use the correct tool (O2 sensor socket) to avoid damaging the sensor or exhaust manifold. Apply anti-seize compound to the sensor threads to prevent corrosion and make future removal easier. Be sure to properly torque the sensor to the manufacturer's specifications.

Future Trends in O2 Sensor Technology

The automotive industry is constantly evolving, and O2 sensor technology is no exception. Future trends include:

- More advanced sensor materials: Researchers are developing new sensor materials that are more durable, accurate, and resistant to contamination.

- Integration with onboard diagnostics: O2 sensors are becoming increasingly integrated with onboard diagnostic systems, providing more detailed information about engine performance and emissions control.

- Smart sensors: Future O2 sensors may incorporate onboard processing capabilities, allowing them to perform self-diagnostics and communicate directly with the ECU.

- Sensors for alternative fuels: As alternative fuels become more prevalent, O2 sensors will need to be adapted to accurately measure the exhaust gas composition of these fuels.

The shift towards electric vehicles (EVs) will eventually reduce the demand for traditional O2 sensors. However, hybrid vehicles will continue to rely on internal combustion engines and O2 sensor technology for the foreseeable future. Furthermore, advancements in hydrogen fuel cell technology may lead to the development of specialized sensors for monitoring fuel cell performance.

Conclusion

The O2 sensors in the 2011 Nissan Altima are critical components of the engine management system, playing a vital role in fuel efficiency, emissions control, and overall vehicle performance. Understanding the technical specifications, engineering choices, and diagnostic considerations related to these sensors is essential for automotive professionals. By following proper maintenance practices and staying informed about future trends, technicians can ensure the continued reliability and performance of the Altima and other vehicles on the road. The automotive industry is undergoing a significant transformation, driven by electrification, automation, and connectivity. As these technologies continue to evolve, automotive professionals must adapt their skills and knowledge to meet the challenges and opportunities of the future.