2012 Nissan Altima Mass Air Flow Sensor

The 2012 Nissan Altima, a popular mid-size sedan, relies on a Mass Air Flow (MAF) sensor as a crucial component of its engine management system. This article delves into the technical specifications, engineering choices, real-world performance, and reliability aspects of the MAF sensor used in this vehicle, comparing it with alternatives and providing maintenance tips for automotive professionals.

Technical Specifications and Engineering Choices

The 2012 Nissan Altima typically uses a hot-wire MAF sensor. This type of sensor is widely employed across various automotive brands due to its relatively simple design and good accuracy. Nissan, in this model year, utilized a design that measured the mass of air entering the engine by measuring the amount of current needed to maintain a heated wire at a constant temperature. As more air flows across the wire, more current is required to keep the wire at its operating temperature. This current reading is then converted into an electrical signal sent to the Engine Control Unit (ECU).

Technical specifics often include:

- Operating Voltage: Typically 5V DC

- Output Signal: Analog voltage signal that varies with airflow. The range usually falls between 0V and 5V.

- Sensor Type: Hot-wire anemometer

- Housing Material: Durable plastic composite resistant to heat and chemicals found in the engine bay.

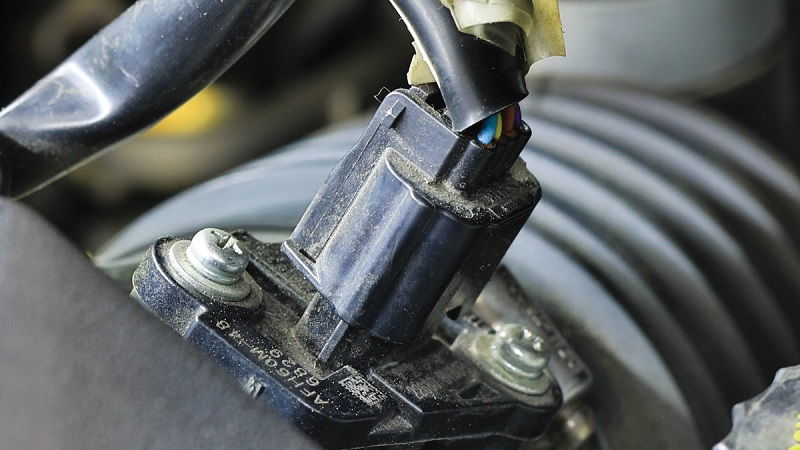

- Mounting Location: Typically located in the intake tract, between the air filter box and the throttle body.

- Connector Type: A multi-pin connector, usually with four or five pins for power, ground, signal, and (sometimes) intake air temperature.

Nissan's engineering choice of using a hot-wire MAF sensor reflects a balance between cost, performance, and reliability. Other technologies, like Karman vortex sensors, existed, but hot-wire sensors generally offer better response time and accuracy, especially in measuring rapidly changing airflow. The sensor is designed to withstand the harsh environment of the engine compartment, including temperature fluctuations, vibrations, and exposure to contaminants. The ECU uses the MAF sensor reading, along with other sensor data, to calculate the correct amount of fuel to inject for optimal combustion.

Comparison with Alternatives

While hot-wire MAF sensors were a common choice, other technologies exist, each with its own advantages and disadvantages:

- Karman Vortex Sensors: These sensors use a bluff body to create vortices in the airflow. The frequency of these vortices is proportional to the airflow rate.

- Pros: Less sensitive to contamination than hot-wire sensors.

- Cons: Slower response time, less accurate at low airflow rates, and generally bulkier.

- Hot-Film Sensors: Similar to hot-wire sensors, but use a thin film instead of a wire.

- Pros: More robust and less prone to breakage than hot-wire sensors.

- Cons: More expensive to manufacture.

- MAP (Manifold Absolute Pressure) Sensors: Some vehicles use a MAP sensor as the primary method of determining engine load. These systems estimate airflow based on manifold pressure and engine speed.

- Pros: Simpler design, less prone to contamination.

- Cons: Less accurate than MAF sensors, especially in engines with variable valve timing or forced induction.

Nissan's choice of a hot-wire MAF for the 2012 Altima balances cost-effectiveness with the need for accurate airflow measurement, which is crucial for maintaining good fuel economy and emissions performance.

Real-World Performance and Reliability

In the real world, the MAF sensor in the 2012 Altima performs reasonably well. However, it is not immune to problems. Common issues include contamination from dirt, oil, and other debris. A dirty MAF sensor can cause a variety of symptoms, including:

- Poor fuel economy

- Rough idling

- Hesitation during acceleration

- Stalling

- Check Engine Light (CEL) with codes such as P0101 (MAF Sensor Circuit Range/Performance) or P0102 (MAF Sensor Circuit Low Input).

Reliability is generally good, but the lifespan of the MAF sensor can be affected by factors such as the quality of the air filter and the maintenance habits of the vehicle owner. A neglected air filter can allow more contaminants to reach the MAF sensor, shortening its lifespan.

The hot-wire design, while offering good accuracy, is inherently more susceptible to contamination compared to other technologies. The thin wire is easily coated with debris, altering its thermal characteristics and affecting its ability to accurately measure airflow. This is a key trade-off to consider.

Maintenance Tips for Automotive Professionals

Proper maintenance is crucial for ensuring the longevity and performance of the MAF sensor. Here are some tips for automotive professionals:

- Regular Inspection: Inspect the MAF sensor during routine maintenance. Look for signs of contamination, such as dirt, oil, or debris on the sensing element.

- Proper Cleaning: If the MAF sensor is dirty, clean it using a MAF sensor cleaner specifically designed for this purpose. Do not use carburetor cleaner or other harsh solvents, as these can damage the sensor.

- Air Filter Replacement: Emphasize the importance of regular air filter replacement to vehicle owners. A clean air filter will prevent contaminants from reaching the MAF sensor.

- Careful Handling: Handle the MAF sensor with care. The sensing element is delicate and can be easily damaged.

- Accurate Diagnosis: Use a scan tool to diagnose MAF sensor problems accurately. Check the MAF sensor readings at idle and during acceleration. Compare the readings to the manufacturer's specifications.

- Check for Air Leaks: Inspect the intake system for air leaks. Air leaks can cause inaccurate MAF sensor readings and lead to engine performance problems.

- Use Quality Replacement Parts: When replacing a MAF sensor, use a high-quality replacement part from a reputable manufacturer. Aftermarket MAF sensors can vary in quality and accuracy.

- Verify the Fix: After cleaning or replacing the MAF sensor, verify the fix by clearing the diagnostic trouble codes and monitoring the MAF sensor readings with a scan tool.

Future Trends

The automotive industry is moving towards more advanced engine management systems that rely on a combination of sensors and sophisticated algorithms. Future trends in MAF sensor technology include:

- Digital MAF Sensors: These sensors provide a digital output signal, which is less susceptible to noise and interference than analog signals.

- Integrated Sensors: Combining MAF sensors with other sensors, such as temperature and humidity sensors, into a single unit.

- Sensorless Systems: Advanced engine control strategies that rely on models and algorithms to estimate airflow without the need for a dedicated MAF sensor. This is more common in newer vehicles that rely more heavily on MAP sensors and predictive modeling.

While MAF sensors may eventually be phased out in some applications, they will likely remain an important component of engine management systems for many years to come, particularly in older vehicles and in applications where high accuracy is required.

Furthermore, the rise of electric vehicles (EVs) doesn't negate the need for professionals skilled in diagnosing and maintaining internal combustion engines (ICE). Hybrid vehicles, which combine both electric and ICE technologies, will continue to be prevalent, demanding expertise in both domains. As such, understanding components like the MAF sensor in older, yet still common vehicles like the 2012 Nissan Altima remains crucial for automotive technicians.

Forward-Looking Note

The automotive industry is undergoing a rapid transformation, driven by factors such as electrification, automation, and connectivity. Automotive professionals must adapt to these changes by continuously learning and upgrading their skills. Staying up-to-date with the latest technologies and diagnostic techniques is essential for success in this dynamic field. While new technologies emerge, understanding the fundamentals of engine management systems, including the role of sensors like the MAF sensor, will continue to be valuable for automotive professionals in the years to come. A deep understanding of these foundational technologies provides a strong base upon which to learn and adapt to the rapidly evolving world of automotive engineering and repair.