2012 Nissan Maxima Alternator Connector

Alright, let's talk about the alternator connector on a 2012 Nissan Maxima. It's a crucial component often overlooked until problems arise. This article dives deep into its function, typical failure modes, testing procedures, and replacement strategies. Think of this as your definitive guide to understanding and troubleshooting this vital connection.

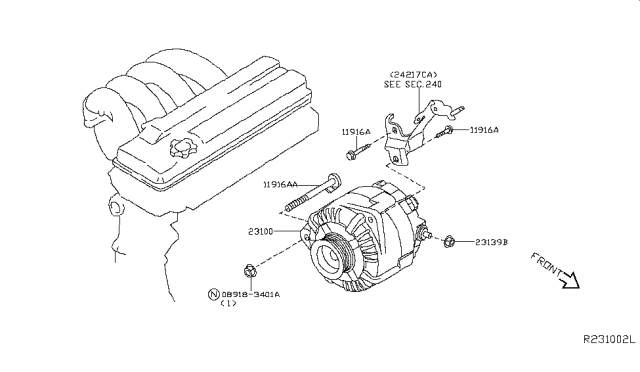

Understanding the 2012 Maxima Alternator Connector

The alternator connector, sometimes referred to as the voltage regulator connector or field connector (though the field is controlled by the ECM in this specific model), is the electrical interface between the vehicle's wiring harness and the alternator itself. On the 2012 Maxima, it's typically a 3-pin connector. The connector provides several essential functions:

- Battery Voltage Sense: This wire tells the alternator the current voltage of the battery. The alternator uses this information to determine how much to charge.

- Ignition Switch Signal: This wire tells the alternator when the engine is running (or at least when the ignition is switched on). Without this signal, the alternator won't charge, even if the engine is running.

- ECM Control/Status: This wire facilitates communication between the Engine Control Module (ECM) and the alternator. The ECM monitors the alternator's performance and adjusts its output based on various factors like engine load and temperature. Modern alternators, like the one on your 2012 Maxima, are often ECM-controlled, meaning the ECM dictates the charging voltage based on sensor data.

It's important to remember that the exact wire colors can sometimes vary slightly depending on the specific sub-model and manufacturing date. Always consult a wiring diagram specific to your vehicle's VIN for absolute certainty.

Common Failure Modes

The alternator connector is exposed to harsh conditions: engine heat, vibration, and moisture. Over time, this can lead to several failure modes:

- Corrosion: This is the most common culprit. Moisture and road salt can seep into the connector, causing the terminals to corrode. Corrosion increases resistance, reducing the flow of electricity and potentially causing intermittent charging or a complete failure. You might see a white or green powdery residue on the terminals.

- Loose Connections: Vibration can loosen the terminals within the connector. This can cause intermittent charging, flickering lights, or even stalling.

- Broken Wires: The wires leading to the connector can become brittle and break, especially near the connector itself due to repeated bending and flexing.

- Melted Connector: Excessive current draw, often caused by a faulty alternator or a short circuit in the charging system, can overheat the connector and cause it to melt or deform. A melted connector is a serious fire hazard and requires immediate attention.

- Pin Fretting: This occurs when there is a minute movement of the connector pins in their sockets. Over time, this wears away the plating on the pins, causing increased resistance and potential signal disruption.

Diagnosing Connector Problems

Identifying a faulty alternator connector requires a systematic approach. Here's a step-by-step guide:

- Visual Inspection: Start with a thorough visual inspection. Look for signs of corrosion, loose wires, melted plastic, or damage to the connector body. A magnifying glass can be helpful for spotting subtle corrosion.

- Voltage Drop Testing: This is a crucial test to determine if there's excessive resistance in the connector. To perform a voltage drop test:

- Set your multimeter to DC voltage.

- With the engine running and the alternator charging (if possible), place one probe on the battery positive terminal and the other probe on the alternator's output terminal. Ideally, the voltage drop should be less than 0.5 volts. A higher voltage drop indicates excessive resistance in the charging circuit, potentially caused by the connector.

- Perform similar voltage drop tests on the ground side, connecting one probe to the alternator case and the other to the battery negative terminal. Again, aim for a voltage drop of less than 0.5 volts.

- Voltage drops higher than 0.5V indicate excessive resistance and requires a further investigation.

- Continuity Testing: With the engine off and the ignition key removed, use a multimeter set to continuity to test the individual wires leading to the connector. Disconnect the connector from the alternator first.

- Test each wire for continuity from the connector to its termination point (e.g., the ECM or ignition switch). A lack of continuity indicates a broken wire.

- Also, check for shorts to ground. There should be no continuity between any of the connector pins and the vehicle's chassis ground.

- Load Testing: If the connector *appears* to be fine visually and passes basic continuity tests, but you still suspect a problem, consider a load test. This involves using a specialized tool to apply a load to the circuit and see if the connector can handle the current. This test is typically performed by professional mechanics.

Repair and Replacement

Depending on the severity of the damage, you have a few options:

- Cleaning and Repair: If the corrosion is minor, you might be able to clean the terminals with a wire brush or specialized electrical contact cleaner. Apply dielectric grease to the terminals after cleaning to prevent future corrosion. If a wire is broken but has enough slack, you can splice it back together using a crimp connector or solder joint. Always use proper soldering techniques and heat shrink tubing to ensure a reliable connection.

- Terminal Replacement: If the terminals are severely corroded or damaged, you can replace them individually. You'll need a terminal extraction tool to remove the old terminals from the connector housing. Purchase new terminals that are compatible with the connector and crimp them onto the wires using a proper crimping tool.

- Connector Replacement: If the connector housing is melted or severely damaged, it's best to replace the entire connector. You can purchase a new connector pigtail from an auto parts store or online retailer. The pigtail will come with a short length of wire attached. Splice the new pigtail into the existing wiring harness, using the same wiring diagram to ensure correct connections. Never just guess at the wire connections!

- Wiring Harness Repair: In severe cases, the damage may extend beyond the connector and into the wiring harness. In this situation, you may need to repair or replace the entire section of the wiring harness. This is a more complex repair that may require the assistance of a professional mechanic.

Important Considerations During Replacement

Before starting any repair, here are some safety considerations:

- Disconnect the Battery: Always disconnect the negative battery cable before working on the electrical system. This prevents accidental short circuits and potential injury.

- Use Proper Tools: Use the correct tools for the job. A proper crimping tool, wire stripper, and soldering iron will ensure a reliable and safe repair.

- Refer to a Wiring Diagram: Always refer to a wiring diagram specific to your vehicle's VIN to ensure correct wire connections.

- Protect the Wires: Protect the wires from abrasion and damage by using wire loom or electrical tape.

- Test Your Work: After completing the repair, test the charging system to ensure that the alternator is charging properly.

Preventative Maintenance

Preventing connector problems is always better than fixing them. Here are a few tips for keeping your alternator connector in good condition:

- Regular Inspection: Inspect the connector regularly for signs of corrosion or damage.

- Dielectric Grease: Apply dielectric grease to the terminals to prevent corrosion.

- Secure the Connector: Ensure that the connector is securely attached to the alternator. A loose connector can vibrate and cause damage.

- Keep the Engine Bay Clean: A clean engine bay will help prevent corrosion and other problems.

By understanding the function, failure modes, and repair procedures for the 2012 Nissan Maxima alternator connector, you can effectively diagnose and resolve charging system problems and keep your vehicle running smoothly. Always remember to prioritize safety and consult a professional mechanic if you're unsure about any aspect of the repair.