2013 Nissan Altima O2 Sensor

The 2013 Nissan Altima, part of the fifth generation (L33) model, represents a significant stride in Nissan's mid-size sedan offerings. Among its many components, the oxygen (O2) sensors play a crucial role in maintaining engine efficiency and reducing emissions. This article delves into the technical specifications, engineering choices, real-world performance, and long-term reliability aspects of the 2013 Altima's O2 sensor system, offering insights for automotive professionals.

Technical Specifications and Functionality

The 2013 Altima typically utilizes two types of O2 sensors: upstream (pre-catalytic converter) and downstream (post-catalytic converter). These sensors are critical for the engine control unit (ECU) to accurately monitor and adjust the air-fuel mixture. The 2.5L QR25DE inline-4 engine, the more common engine option, generally employs two O2 sensors, while the 3.5L VQ35DE V6 engine will have four sensors - two upstream and two downstream.

Upstream O2 Sensors

Upstream sensors are typically wideband air-fuel ratio sensors. These sensors provide a precise measurement of the air-fuel ratio entering the catalytic converter. Unlike traditional zirconia O2 sensors that produce a voltage signal which varies around stoichiometry (14.7:1 air-fuel ratio), wideband sensors output a current signal that is proportional to the air-fuel ratio across a wider range. The 2013 Altima uses these precise measurements to ensure the engine operates at peak efficiency and optimal performance. The specific connector type and pinout will vary but are typically four-wire sensors (heater, signal, ground, and a calibration/pumping current wire).

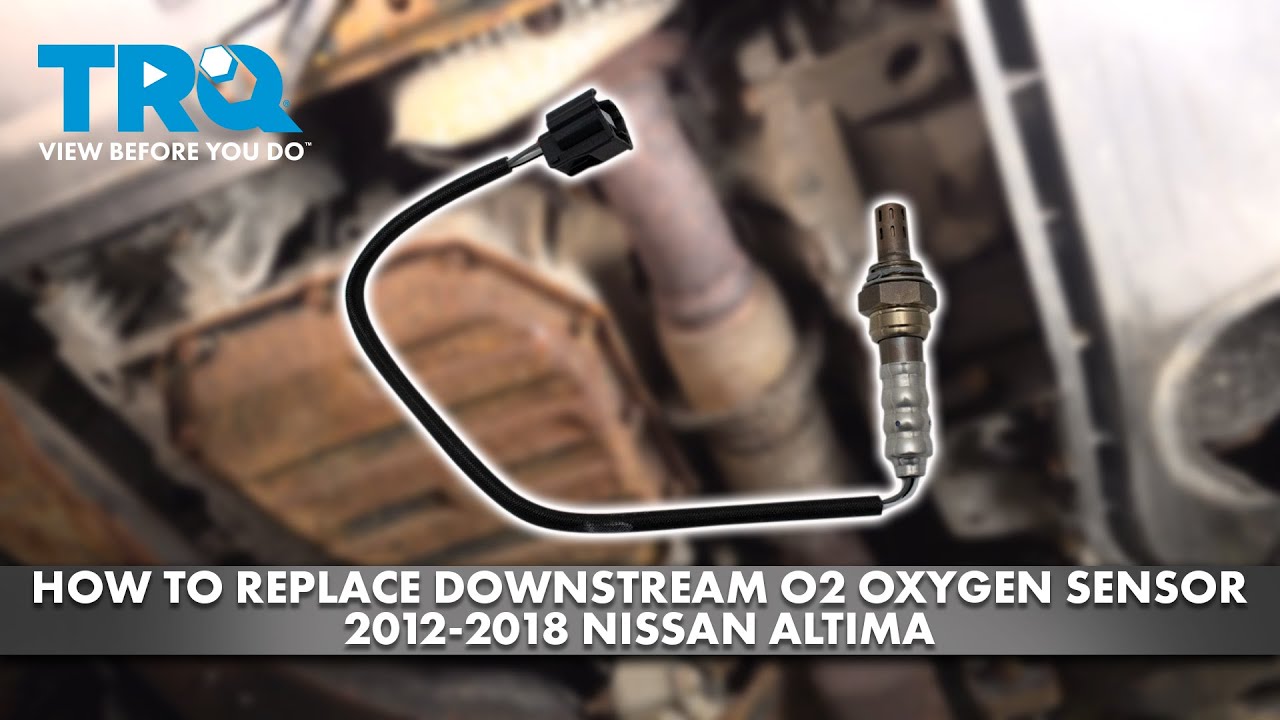

Downstream O2 Sensors

Downstream sensors, located after the catalytic converter, are typically standard zirconia O2 sensors. Their primary function is to monitor the efficiency of the catalytic converter. The downstream sensor detects the oxygen content in the exhaust after it has passed through the converter. A properly functioning catalytic converter will reduce the oxygen content, resulting in a different signal compared to the upstream sensor. If the downstream sensor signal closely matches the upstream signal, it indicates that the catalytic converter is not operating efficiently, potentially triggering a diagnostic trouble code (DTC).

The sensors typically operate within a temperature range of 300-800°C (572-1472°F). The heater element within the sensor ensures it reaches operating temperature quickly, allowing for accurate readings even during cold starts. The sensors are constructed using durable materials like zirconia and platinum to withstand the harsh exhaust environment.

Engineering Choices and Alternatives

Nissan's choice of wideband sensors for the upstream position reflects a commitment to precise air-fuel control. The advantages of wideband sensors compared to traditional narrowband sensors include:

- Improved accuracy: Wideband sensors provide a more linear and accurate reading of the air-fuel ratio across a wider range.

- Enhanced engine control: The ECU can use this precise information to make finer adjustments to fuel injection and ignition timing, resulting in better fuel economy and reduced emissions.

- Faster response time: Wideband sensors react more quickly to changes in the air-fuel ratio, allowing for more responsive engine control.

While other manufacturers might opt for a different combination of sensor types, the wideband/zirconia combination offers a balance between accuracy, cost, and reliability. Alternative sensor technologies, such as titania O2 sensors, are less common due to their slower response time and greater sensitivity to contamination.

OEM sensors are typically manufactured by companies like Denso or NTK (NGK), both of whom are known for their quality and reliability. Aftermarket alternatives are available from various brands, but it is crucial to choose reputable brands to ensure accurate readings and longevity. Cheaper, unbranded sensors often exhibit performance issues and can trigger false DTCs.

Real-World Performance and Reliability

In real-world scenarios, the 2013 Altima's O2 sensors contribute significantly to the vehicle's overall performance and emissions compliance. A properly functioning O2 sensor system ensures optimal fuel efficiency, smooth engine operation, and minimal emissions. However, the harsh operating environment can lead to sensor degradation over time.

Common symptoms of a failing O2 sensor include:

- Decreased fuel economy: An inaccurate O2 sensor can cause the ECU to miscalculate the air-fuel mixture, leading to excessive fuel consumption.

- Rough idling or stalling: An incorrect air-fuel mixture can also cause the engine to idle roughly or stall.

- Increased emissions: A malfunctioning catalytic converter (often related to a faulty O2 sensor) can result in higher emissions.

- Check engine light (CEL): The ECU will typically trigger a CEL with codes such as P0130-P0167, P0420 (catalytic converter efficiency below threshold), indicating a problem with the O2 sensor or catalytic converter system.

The reliability of the O2 sensors can be affected by factors such as:

- Contamination: Oil leaks, coolant leaks, and excessive carbon buildup can contaminate the sensor, leading to inaccurate readings.

- Physical damage: Impacts from road debris can damage the sensor.

- Normal wear and tear: Over time, the sensor's sensing element can degrade, reducing its accuracy and response time.

The typical lifespan of an O2 sensor is around 60,000 to 100,000 miles, but this can vary depending on driving conditions and maintenance practices. Frequent short trips, aggressive driving, and neglecting regular maintenance can shorten the sensor's lifespan.

Maintenance Tips and Best Practices

Regular maintenance is crucial for extending the lifespan of the O2 sensors and maintaining optimal engine performance. Here are some maintenance tips for automotive professionals:

- Visual inspection: Regularly inspect the O2 sensors for any signs of physical damage or contamination.

- Diagnostic scan: Use a diagnostic scan tool to check for any O2 sensor-related DTCs.

- Live data monitoring: Monitor the O2 sensor voltage or current readings using a scan tool to assess their performance. Compare upstream and downstream readings to evaluate catalytic converter efficiency.

- Proper installation: When replacing an O2 sensor, use the correct torque specifications and apply anti-seize compound to the threads to prevent future corrosion.

- Address underlying issues: If a sensor fails prematurely, investigate the underlying cause, such as oil leaks or coolant leaks, and address them to prevent future sensor failures.

- Use quality replacement parts: Use reputable OEM or aftermarket O2 sensors to ensure accurate readings and longevity.

When diagnosing O2 sensor issues, it's important to differentiate between a faulty sensor and other engine-related problems that can affect the sensor readings. For example, a vacuum leak can cause a lean air-fuel mixture, which will affect the upstream O2 sensor readings. Similarly, a faulty fuel injector can cause a rich air-fuel mixture.

Future Trends and Automotive Industry Outlook

The automotive industry is rapidly evolving, with increasing emphasis on fuel efficiency, reduced emissions, and advanced engine management systems. Future trends in O2 sensor technology include:

- More sophisticated sensors: Development of more precise and durable sensors with extended lifespans.

- Integrated sensors: Integration of O2 sensors with other sensors, such as NOx sensors and particulate matter sensors, to provide a more comprehensive picture of the exhaust composition.

- Improved diagnostic capabilities: Advanced diagnostic algorithms that can detect sensor degradation and predict sensor failures before they occur.

- Sensors for alternative fuels: Development of O2 sensors specifically designed for vehicles running on alternative fuels, such as ethanol and hydrogen.

As emission regulations become stricter and vehicles become more complex, the role of O2 sensors will continue to be critical. Automotive professionals need to stay updated on the latest O2 sensor technologies and diagnostic techniques to effectively service and repair modern vehicles.

The shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) will undoubtedly impact the demand for traditional O2 sensors in the long term. However, HEVs will still rely on internal combustion engines and O2 sensor systems, while the servicing and maintenance of existing gasoline-powered vehicles will continue to require skilled technicians with expertise in O2 sensor diagnosis and repair for many years to come. Furthermore, advances in synthetic fuels and carbon capture technologies could potentially extend the lifespan of internal combustion engines, preserving the relevance of O2 sensor technology.

The automotive industry is undergoing a transformation, but the fundamental principles of engine management and emissions control remain important. Automotive professionals who embrace lifelong learning and adapt to new technologies will be well-positioned to thrive in the evolving automotive landscape. Understanding the intricacies of components like the O2 sensor in the 2013 Nissan Altima, while seemingly specific, provides a solid foundation for understanding broader trends and advancements in automotive technology. By focusing on both the present and future of automotive systems, professionals can ensure they remain valuable assets in a rapidly changing industry.